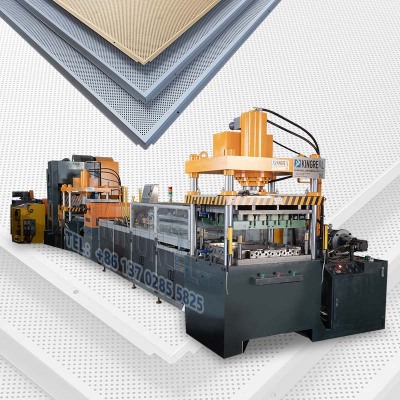

Metal Ceiling Tiles Fleece Gluing Machine

KINGREAL CEILING MACHINERY can provide the metal perforated ceiling coating machine, which mainly used to stick a non-woven the back of the perforated ceiling tile.

KINGREAL CEILING MACHINERY can customize different metal ceiling tile production line manufacturing solutions to suit the needs of KINGREAL CEILING MACHINERY's customers. Please feel free to contact us.

- KINGREAL CEILING MACHINERY

- China

Details

Video About Metal Ceiling Tiles Glue Coating Machine

What is Fleece Coating Machine For Metal Ceilings?

KINGREAL CEILING MACHINERY Metal Ceiling Tile Glue Coating Machine, also called Acoustic Fabric Sticking Machine, which is design for laminating ceiling fabrics. It can make the non-woven to be automatically laid, positioned and laminated to improve the efficiency and quality of the work.

This Acoustic Sheet Coating Machine mainly contains following procedures: Automatic loading, Cutting, Textile Sticking, Flattening, Final Product Output. It is the first choice for metal ceiling tiles manufacturers. The use of Perforated Ceiling Coating Machine reduces manual operations and errors, improving the quality and efficiency of the work.

This sheet coating machine increases efficiency and reduces labour costs, while also ensuring the quality and consistency of the acoustic ceiling panels. It is often used for sticking an acoustic non-woven on the back of the perforated ceiling tile.

KINGREAL CEILING MACHINERY Metal Ceiling Tiles Fleece Coating Machine Installation Cases

As an important part of the metal ceiling machine, KINGREAL CEILING MACHINERY metal ceiling tiles fleece gluing machine has achieved remarkable success in the market and has been widely sold to many countries and regions such as the UAE, Saudi Arabia, Indonesia, Turkey, Egypt and Qatar.

Customers in these markets generally give high praise to the efficiency and reliability of KINGREAL CEILING MACHINERY metal ceiling tiles fleece gluing machine. In order to ensure that customers can make full use of KINGREAL CEILING MACHINERY metal ceiling tiles fleece gluing machine, KINGREAL CEILING MACHINERY engineering team will go to the customer's factory for on-site installation and commissioning services. This service not only ensures the smooth operation of the equipment, but also helps customers quickly integrate the collaborative operation of the patch machine and the metal ceiling tile production line in actual production.

KINGREAL CEILING MACHINERY metal ceiling tiles fleece gluing machine is perfectly matched with the aluminum ceiling tile machine to form a complete patch ceiling production process. Through this process, customers can achieve efficient production and ensure that each piece of ceiling has excellent appearance and performance.

The metal ceiling tiles fleece gluing machine is designed to improve production efficiency and reduce material waste while ensuring the quality and durability of the patch.

Working Process of Fleece Coating Machine For Metal Ceilings

Fleece Sticking Section -- Drying Section -- Air-Fan Cooling Section

Specification of Glue Coating Machine

| Weight (KG) | 5000 |

| Core Components | PLC, Motor |

| Textile install speed | 10PCS/min |

| Suitable perforated ceiling tile size | 600*600mm, 300*300mm or other size |

| Voltage | 380 / 50 HZ / 3 PHASE |

What Can Glue Coating Machine Provide?

※ Lower labor cost

|  |

Combination With Metal Ceiling Tile Production Line

Sticking an acoustic fleece on the back of the perforated ceiling tile can increase the degree of sound-absording of the metal ceiling panels. As a professional metal cailing tile making machine suppplier in China, KINGREAL CEILING MACHINERY also can provide complete metal ceiling tile production line, including different sizes of metal ceiling tile production line and perforated ceiling tiles production line.

Combination Acoustic Fabric Sticking Machine and metal ceiling tile production line is a choice of many of KINGREAL CEILING MACHINERY ceiling tiles manufacturer customers, also is beneficial for facilitating consistency in metal ceiling panels production.

|  |

| 30*30 cm / 60*60 cm / 60*120 cm Metal Ceiling Tile Production Line | Perforated Metal Ceiling Production Line |

Why Are Acoustic Ceiling Panels so Popular?

The main function of an acoustic metal ceiling is to reduce noise and echoes in the room and to improve sound quality and speech intelligibility. It absorbs sound waves from audio equipment, human voices, machine noise etc. and reduces their bounce and diffusion in the room, thus reducing noise levels and improving the clarity of sound.

Acoustic ceilings are often used in recording studios, concert halls, theatres, conference rooms, restaurants and other places where good sound quality and a comfortable environment are required.

How KINGREAL CEILING MACHINERY Ensure The Quality of Metal Ceiling Tiles Fleece Gluing Machine

Establish a strict quality system

In order to better control the quality of the machine, KINGREAL CEILING MACHINERY has established its own factory and technical team. KINGREAL CEILING MACHINERY has established standardized work process standards to ensure that the machine maintains a high standard from manufacturing to debugging. From the selection of parts to the debugging of the machine, KINGREAL CEILING MACHINERY team works strictly in accordance with the standards. To provide customers with professional and high-quality machines, in order to fulfill this promise, KINGREAL CEILING MACHINERY has subdivided the work into every step.

Quality certified

KINGREAL CEILING MACHINERY has passed ISO9000 certification and has the ability of ISO9000 quality system management. It has also passed the international CE certificate certification.

KINGREAL CEILING MACHINERY in Diverse Exhibition

KINGREAL CEILING MACHINERY attaches great importance to market promotion and brand building, and actively participates in various international exhibitions. It has participated in the Canton Fair, Russian exhibitions and industry exhibitions in other regions many times to showcase KINGREAL CEILING MACHINERY innovative technologies and product solutions. At these exhibitions, KINGREAL CEILING MACHINERY metal ceiling machine, baffle ceiling machine, open cell ceiling machine, linear strip ceiling machine and metal sheet perforation line and other special machines attracted a lot of attention and inquiries from customers.

The exhibition is not only a platform for product display, but also an important opportunity to communicate with customers and understand market needs. At the exhibition, customers can actually see the operation of KINGREAL CEILING MACHINERY equipment, and have in-depth exchanges with technical experts to obtain professional technical support and solutions. This face-to-face communication greatly enhances customers' trust in the KINGREAL CEILING MACHINERY brand, and also helps us collect valuable market feedback information.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)