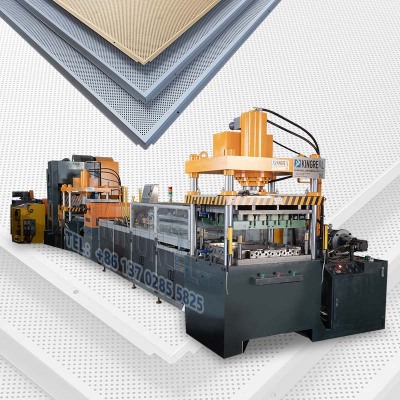

Aluminum Ceiling Tile Machine

KINGREAL CEILING MACHINERY aluminum ceiling tile machine can provide customized manufacturing solutions according to customer drawings. It has the characteristics of fast production speed, high degree of automation and high precision.

- KINGREAL CEILING MACHINERY

- China

Details

Video About Aluminum Ceiling Tile Machine

Introduction to Aluminum Ceiling Tile Machine

In modern architecture and interior decoration, metal ceiling tiles are not only the embodiment of functional design, but also an important part of aesthetics. KINGREAL CEILING MACHINERY Aluminum ceiling tile machine is designed for the production of decorative metal ceiling panels, which can flexibly respond to market demand and meet customers' requirements for different thicknesses, widths and materials. Whether it is home, hotel, office, hospital or subway station, KINGREAL CEILING MACHINERY can provide high-quality aluminum ceiling tile production line manufacturing solutions.

KINGREAL CEILING MACHINERY aluminum ceiling tile production line is known for its high automation, high precision and high-speed production. By changing the mold, customers can easily achieve the production of two types of metal ceiling panels, Clip In metal ceiling tile and Lay In metal ceiling board, on the same aluminum ceiling tile machine. This flexibility enables the aluminum ceiling tile production line to quickly adapt to market changes and meet diverse customer needs.

In addition, KINGREAL CEILING MACHINERY can equip the aluminum ceiling tile machine with different components and adjust parameters according to the specific requirements of customers. Whether it is production speed, material selection, or specific functions, KINGREAL CEILING MACHINERY team of engineers can provide professional customized solutions to ensure the efficient operation of the aluminum ceiling tile production line.

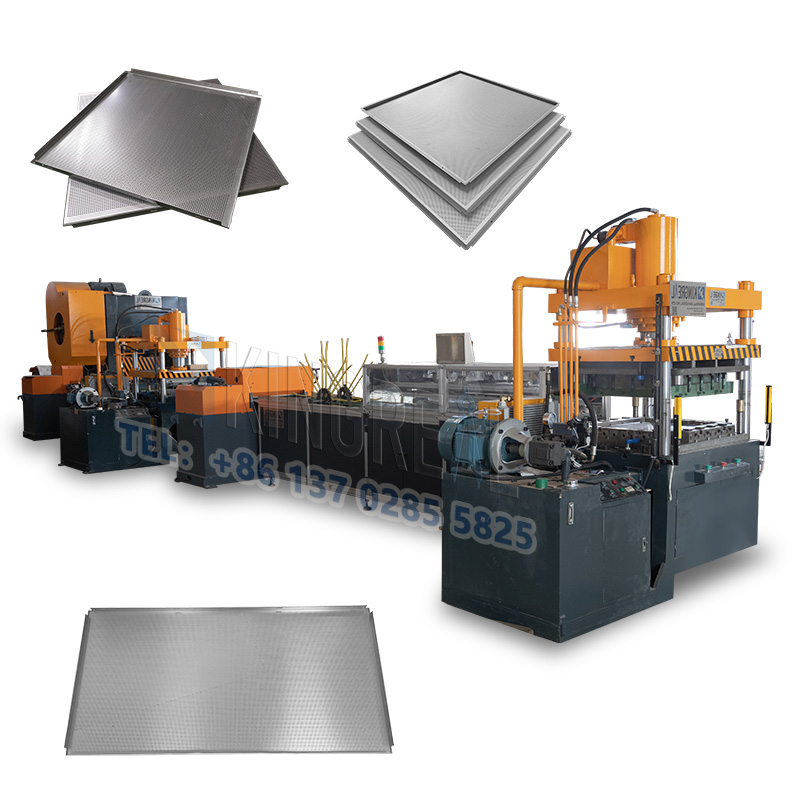

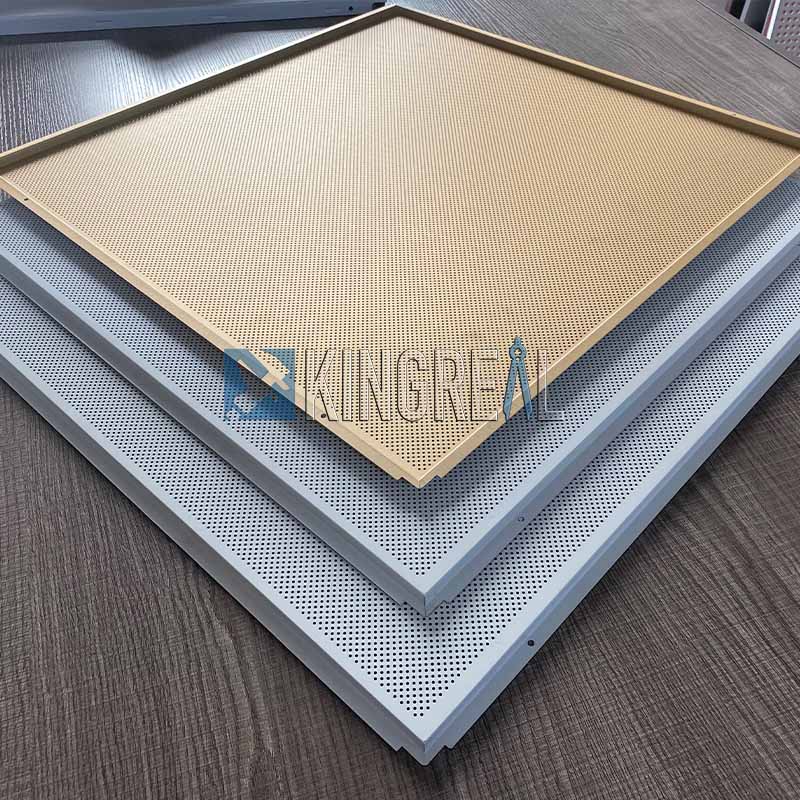

The aluminum ceiling tiles produced by KINGREAL CEILING MACHINERY aluminum ceiling tile machine are also guaranteed in quality. Each piece of metal ceiling board is burr-free and has a smooth surface. The aluminum ceiling boards produced under the same parameters are highly consistent, ensuring the stability and reliability of customers during mass production.

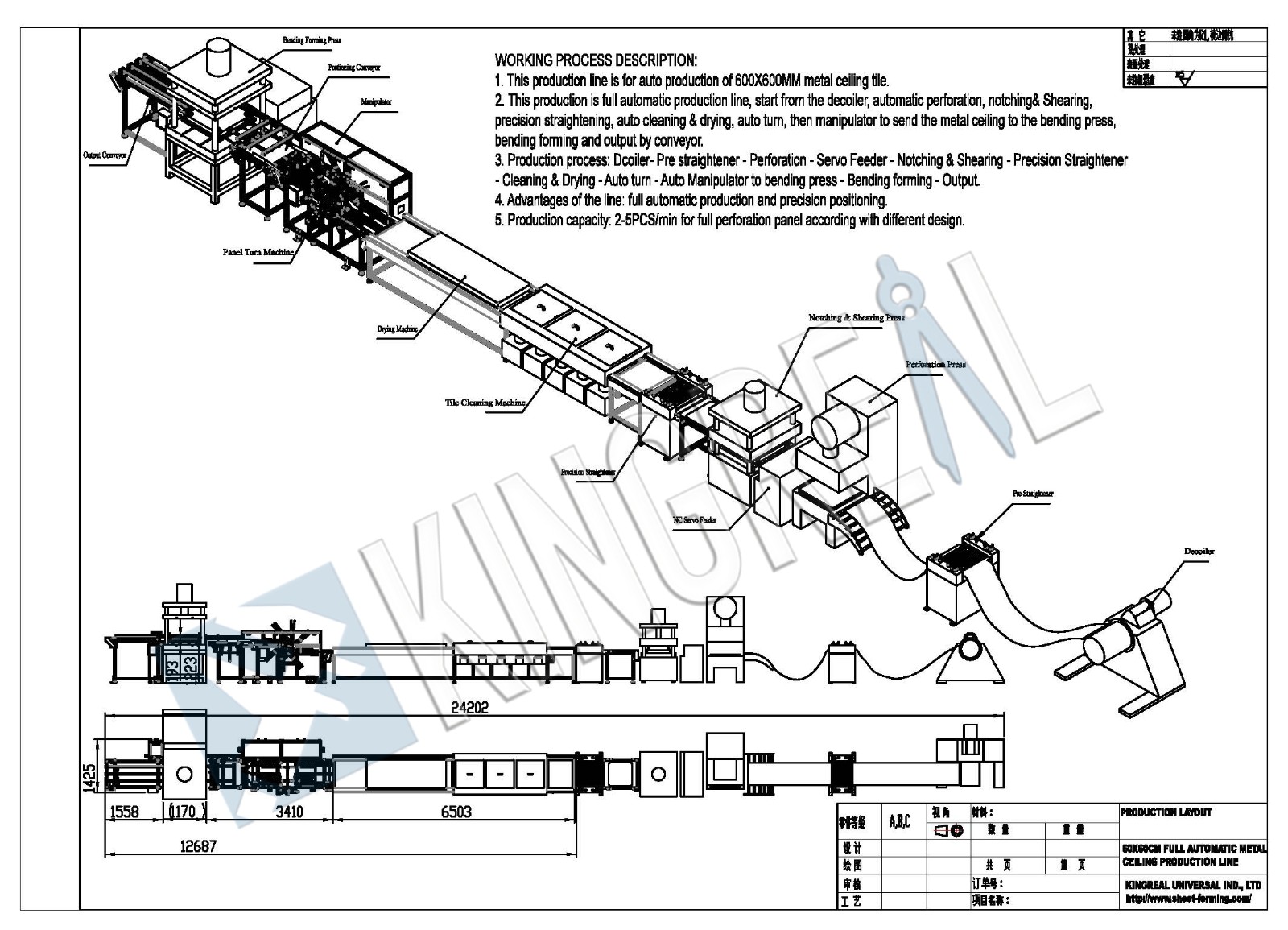

Workflow of Aluminum Ceiling Tile Production Line

Hydraulic Decoiler

↓

Precision Straightener

↓

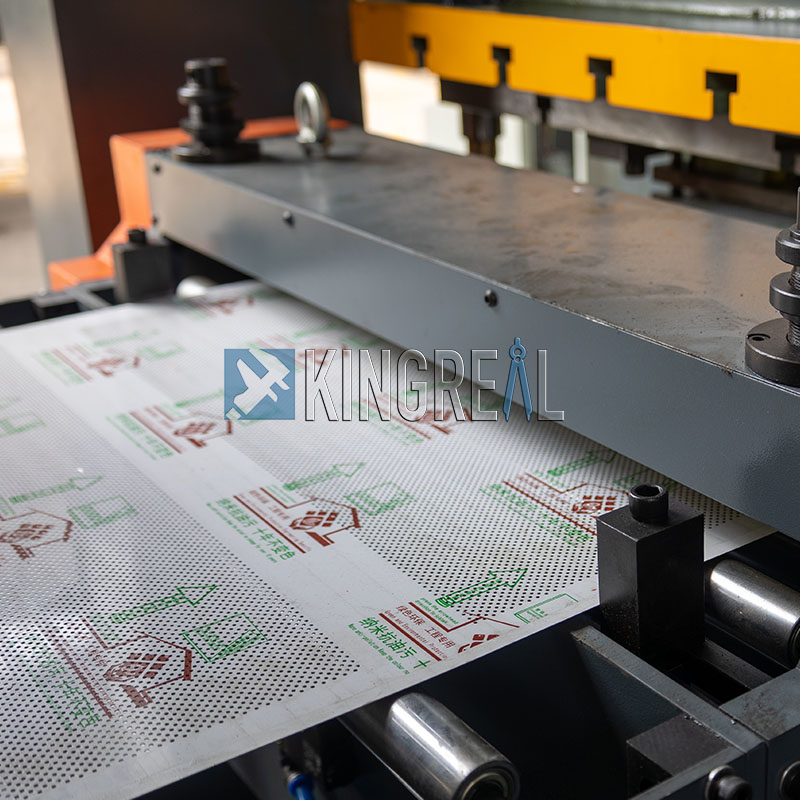

Punching Machine

↓

Servo Feeding Machine

↓

Notching And Shearing Press

↓

2nd Precision Straightener

↓

Flipping machine

↓

Automatic tiles feeding machine

↓

Auto Bending Forming Machine

Parameters of Aluminum Ceiling Tile Machine

| Hydraulic decoiler | Width of material | <700mm |

| Maximum load | 5 tons | |

| Precision straightener | Width of material | <700mm |

| Thickness of material | 0.3-2.2mm | |

| Feeding speed | 25m/min | |

| High speed punching machine | Output pressure force | 125 tons |

| Punching rows | 4 rows for gi steel material 8 rows for aluminum material | |

| Punching stroke | 20mm | |

| Adjustable thickness | 10mm | |

| Punching pierce | 150-180times/min(3-5pcs tiles/min) | |

| Hydraulic notching & shearing press | Cylinder pressure force | 60 tons |

| Cylinder stroke | 200mm | |

| 120 ton hydraulic bending press (automatic) | Main cylinder pressure force | 100 tons |

| Master cylinder stroke | 350mm | |

| Lower cylinder pressure force | 20 tons | |

| Lower cylinder pressure stroke | 150mm |

Main Components of Aluminum Ceiling Tile Production Line

| Components | Auto Aluminum ceiling tile machine | Semi-automatic Auto Aluminum ceiling tile machine |

| Hydraulic Decoiler | Automatically unfold the metal coil to adapt to different diameters and ensure stable material supply | |

| Precision Straightener | A total of 21 rollers, 10 rollers on the top and 11 rollers on the bottom, the purpose is to straighten the metal strip before punching | |

| Punching Machine | There are punching machines with different parameters to choose from, and by replacing the punching die, one aluminum ceiling tile machine can produce metal ceiling boards with different hole sizes | |

| Servo Feeding Machine | Accuracy ±0.02mm, motor power 3.0KW, the purpose is to automatically send the metal coil to the next component | |

| Notching And Shearing Press | Automatically adjust the cutting parameters to adapt to different material thicknesses to ensure accuracy | |

| 2nd Precision Straightener | Secondary flattening of metal sheets to ensure surface flatness | |

| Flipping Machine | Automatically flip the material to reduce the risk of workers' operation and improve efficiency | No flipping machine, manual flipping is required, increasing labor intensity |

| Automatic Tiles Feeding Machine | Automatically feed the sheet into the bending forming machine to improve production efficiency | No automatic tiles feeding manipulator, relying on manual operation |

| Auto Bending Forming Machine | Fast and accurate pressing and forming, adapting to a variety of product types | No automatic bending forming machine, manual intervention may affect production speed and finished product consistency |

Why choose KINGREAL CEILING MACHINERY Aluminum Ceiling Tile Machine?

1. Fully automated, improved productivity

KINGREAL CEILING MACHINERY fully automated aluminum ceiling tile production line integrates a number of advanced technologies, greatly improving production efficiency while effectively reducing labor costs. KINGREAL CEILING MACHINERY aluminum ceiling tile machine is equipped with automated components such as flipping machines, automatic tiles feeding machines and auto bending forming machines.

1.1 Flipping machine for metal ceiling machine The flipping machine design in the aluminum ceiling tile production line allows the material plate to automatically flip 180 degrees, thereby ensuring the continuity and smoothness of the production process. This automated step not only reduces the need for manual handling, but also reduces the errors that may occur due to human operation. |  |

1.2 Automatic tiles feeding machine for metal ceiling machine The automatic tiles feeding machine can accurately deliver the material to the position of the forming press, reducing the instability and delays caused by traditional manual feeding. Through this link, the aluminum ceiling tile production line can achieve a higher production speed and ensure that each production link can operate efficiently. |  |

1.3 Auto bending forming machine for metal ceiling machine The auto bending forming machine is a crucial equipment in the aluminum ceiling tile machine process. KINGREAL CEILING MACHINERY auto bending forming machine can complete the forming of the aluminum ceiling tiles in one press, ensuring the consistency and high quality of the product. This efficient production method enables companies to meet the needs of large orders in a short time. |  |

2. Flexible solution selection

In order to meet the needs of different customers in the market, KINGREAL CEILING MACHINERY provides two aluminum ceiling tile production line solutions: fully automatic and semi-automatic.

2.1 Fully automatic aluminum ceiling tile production line The fully automatic aluminum ceiling tile machine is suitable for large-scale production, which can effectively reduce labor costs and production time, and is suitable for enterprises pursuing high efficiency and high output. |  |

2.2 Semi-automatic aluminum ceiling tile production line For some small and medium-sized enterprises, or customers who are new to metal ceiling tile production, the semi-automatic aluminum ceiling tile production line is an ideal choice. Although the semi-automatic aluminum ceiling tile machine eliminates equipment such as flipping machines and automatic tiles feeding machines, the technical parameters of other key components such as decoilers, precision straighteners, perforation presses, servo feeding machines, and notching and shearing presses are the same as those of fully automatic aluminum ceiling tile production lines. As the scale of production expands, customers can also easily upgrade to fully automatic aluminum ceiling tile machines to ensure the flexibility and sustainable development of the enterprise. |  |

3. Diversified product sizes and types KINGREAL CEILING MACHINERY aluminum ceiling tile production line can produce metal ceiling panels of various sizes and types to meet the personalized needs of different customers. The sizes of metal ceiling boards that can be produced by KINGREAL CEILING MACHINERY aluminum ceiling tile production line include but are not limited to: 600 x 600 mm, 300 x 300 mm, 300 x 600 mm, 300 x 1200 mm, 600 x 1200 mm. In addition, the types of metal ceiling tiles that can be produced by the aluminum ceiling tile production line include Lay In aluminum ceiling tiles, Lay On aluminum ceiling tiles, Clip In aluminum ceiling tiles and Tegular aluminum ceiling tiles, ensuring that the market needs for metal ceiling boards of different styles and functions can be met. |  |

4. Perfect match with metal ceiling tile perforation line In order to meet customers' diverse needs for metal ceiling boards, KINGREAL CEILING MACHINERY aluminum ceiling tile machine can perfectly match with the metal ceiling tile perforation line to produce metal ceiling tiles without holes, half holes and full holes. Common punching diameters include φ0.8 mm, φ1.8 mm, φ2.3 mm, φ2.5 mm and φ3.0 mm, ensuring the flexibility and adaptability of the product. |  |

5. Efficient production process

KINGREAL CEILING MACHINERY aluminum ceiling tile production line can be perfectly matched with a variety of components to form a complete and efficient metal ceiling board production process. These components include:

5.1 Acoustic fleece sticking machine The acoustic fleece sticking machine can automatically apply sound-absorbing cloth to the metal ceiling panel to produce sound-absorbing metal ceiling tiles with good sound insulation. This function greatly increases the added value of the product and meets customers' needs for a comfortable environment. |  |

5.2 Metal sheet cleaning machine The metal sheet cleaning machine is responsible for cleaning the surface of the produced metal ceiling board, removing dust and oil, and ensuring that the product is in perfect condition before leaving the factory. A good cleaning process not only improves the appearance of the product, but also provides convenience for subsequent installation. |  |

5.3 Feeding trolley The feeding trolley equipped with the decoiler makes the production process more efficient and automated, reduces the complexity of manual operation, and improves the overall metal ceiling tiles production efficiency. |  |

6. Precision manufacturing to ensure product quality KINGREAL CEILING MACHINERY aluminum ceiling tile production line adopts precision manufacturing technology to ensure the high quality of each component. For example, the precision straightener adopts a 21-roller design, including 10 upper rollers and 11 lower rollers, which makes the plate flatter during the production process and improves the quality of the finished product. At the same time, the punching die uses CR12 or CR12MOV material, and the hardness reaches HRC58-60 after heat treatment, ensuring the durability and service life of the die. |  |

How to Ensure the Quality of Aluminum Ceiling Tile Machine?

● Professional design team KINGREAL CEILING MACHINERY has an experienced professional design team that can design solutions based on the drawings provided by customers and in combination with actual production needs. This means that the machine parameters and performance customized by KINGREAL CEILING MACHINERY for each customer are unique, ensuring that personalized production requirements are met. ● Professional manufacturing team KINGREAL CEILING MACHINERY manufacturing team is composed of professionals with more than ten years of aluminum ceiling tile machine manufacturing experience per person, who maintain a rigorous and serious attitude in every production process. In order to ensure the quality of each aluminum ceiling tile production line, KINGREAL CEILING MACHINERY also has a special team to regularly test and evaluate the machine components in the workshop to ensure that all components meet strict quality standards. Through these two efforts, KINGREAL CEILING MACHINERY can effectively guarantee the high quality of the aluminum ceiling tile machine and meet the expectations and needs of customers. |  |

Aluminum Ceiling Tile Machines to Meet a Variety of Needs

KINGREAL CEILING MACHINERY aluminum ceiling tile production line can process and produce different metal raw materials such as aluminum or iron, and can produce various types of metal ceiling boards such as plain metal ceiling tiles, perforated metal ceiling boards, aluminum ceiling panels with sound-absorbing cloth, Clip In metal ceiling tiles, Lay In metal ceiling panels, Tegular metal ceiling tiles and so on.

If you have special aluminum ceiling tiles needs, please consult KINGREAL CEILING MACHINERY. KINGREAL CEILING MACHINERY engineers will provide you with customized aluminum ceiling tile production line manufacturing solutions to ensure that your production needs are optimally solved.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)