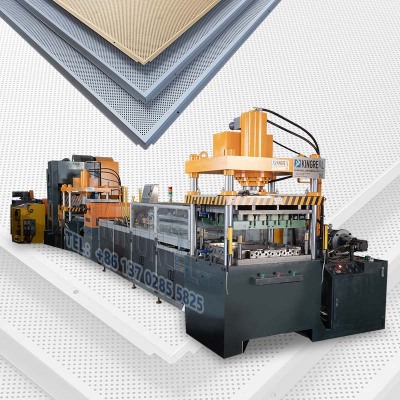

Metal Ceiling Machine

KINGREAL CEILING MACHINERY can provide different solutions for metal ceiling machines according to the actual production situation of customers. And KINGREAL CEILING MACHINERY can also provide false ceiling channel machines (u channel machines, wall angle machines, furring channel machines, CD UD profile machines), ceiling t bar machines, spring tee clip in carrier roll forming machines, A-type carrier roll forming machines and other roll forming machines to meet customers' needs for a complete ceiling system.

- KINGREAL CEILING MACHINERY

- China

Details

Video About Metal Ceiling Machine

Introduction of Metal Ceiling Machine

KINGREAL CEILING MACHINERY can provide different solutions for metal ceiling machines according to the actual production situation of customers. Including fully automatic metal ceiling tile production lines, semi-automatic metal ceiling tile production lines, etc., and KINGREAL CEILING MACHINERY metal ceiling machines can produce various types of metal ceiling tiles such as clip in ceiling tile, lay in ceiling tile, tegular ceiling tile, etc., and can also provide metal ceiling tiles of different sizes according to customer needs, such as 30x30cm, 60x60cm, 60x120cm, etc. In addition, KINGREAL CEILING MACHINERY can also provide a one-stop solution for metal ceiling systems. Provide false ceiling channel machines (u channel machines, wall angle machines, furring channel machines, CD UD profile machines), ceiling t bar machines, spring tee clip in carrier roll forming machines, A-type carrier roll forming machines and other roll forming machines. The profiles produced by these roll forming machines are necessary for installing metal ceiling boards. Use these roll forming machines with metal ceiling machines, KINGREAL CEILING MACHINERY provides customers with a complete set of metal ceiling tile solutions. |  |

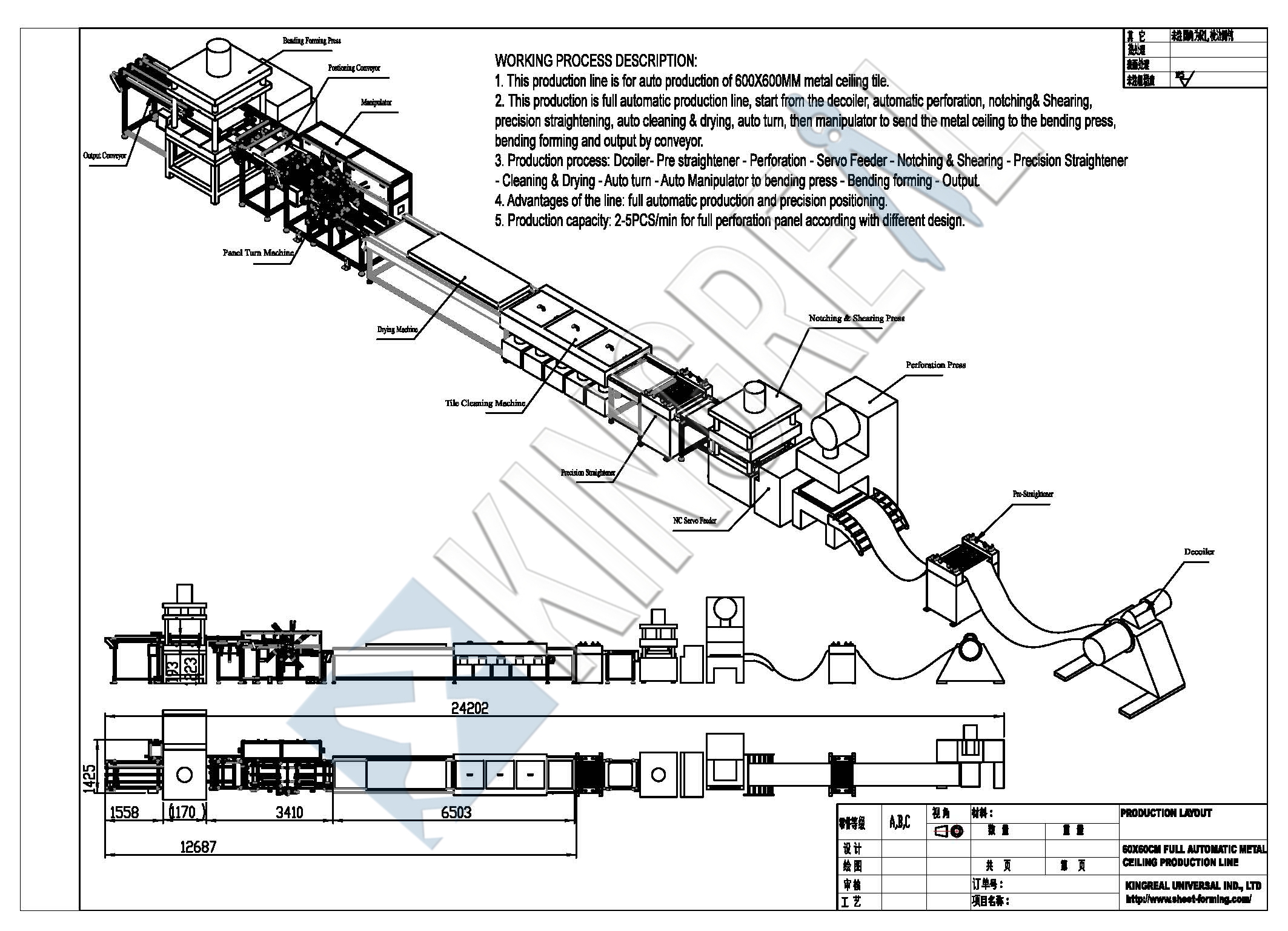

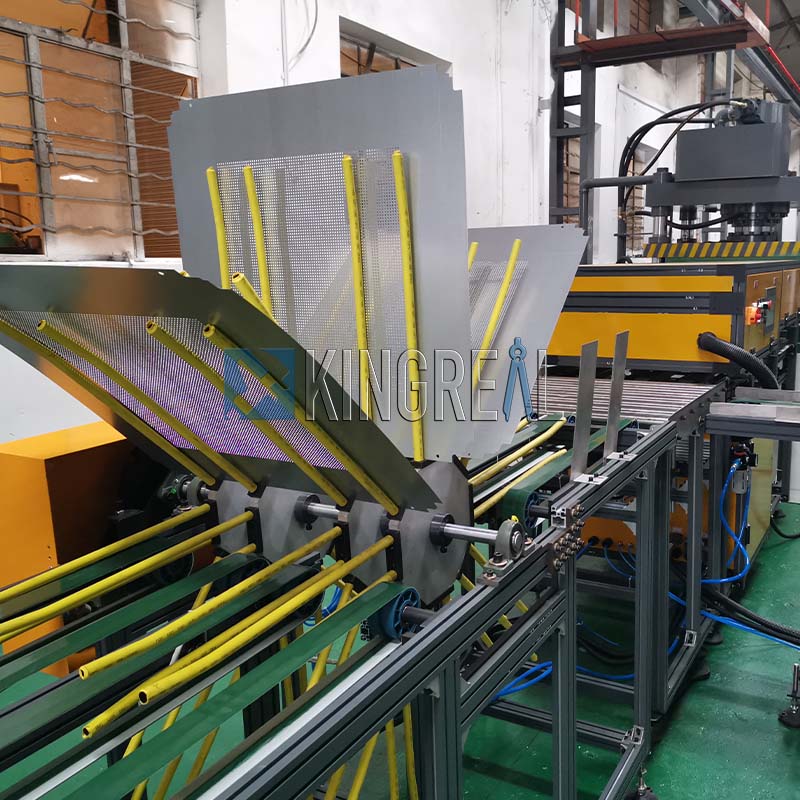

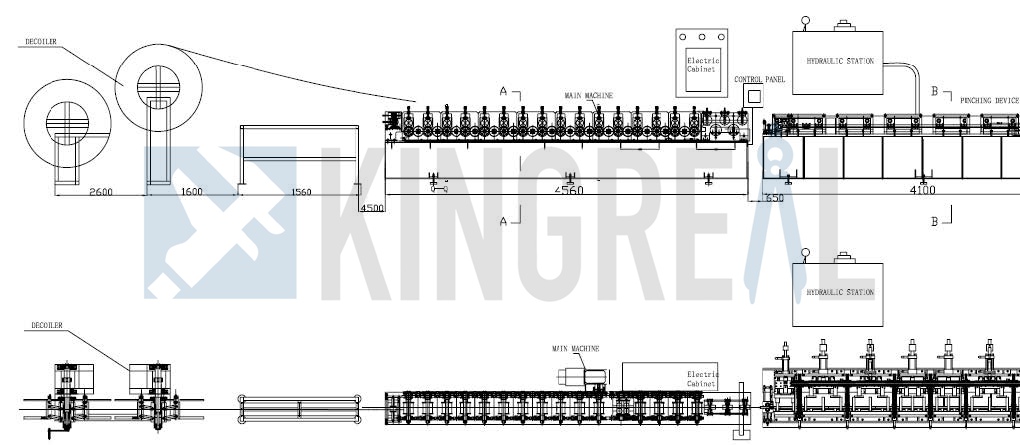

Working Process of Metal Ceiling Machine

Hydraulic Decoiler -- Precision Straightener -- Punching Machine -- Servo Feeding Machine -- Notching And Shearing Press -- 2nd Precision Straightener -- Flipping machine -- Automatic tiles feeding machine--Auto Bending Forming Machine

Parameters of Metal Ceiling Machine

Metal Ceiling Tile Production Line | ||

| Hydraulic decoiler | Width of material | <700MM |

| Maximum load | 5Tons | |

Precision straightener | Width of material | <700MM |

| Thickness of material | 0.3-2.2MM | |

| Feeding speed | 25m/min | |

High speed punching machine | Output pressure force | 125Tons |

| Punching rows | 4rows for gi steel material, 8rows for aluminum material | |

| Punching stroke | 20MM | |

| Adjustable thickness | 10MM | |

| Punching pierce | 150-180times/min | |

Hydraulic notching & shearing press | Cylinder pressure force | 60Tons |

| Cylinder stroke | 200MM | |

120Ton hydraulic bending press (automatic) | Main cylinder pressure force | 100Tons |

| Master cylinder stroke | 350MM | |

| Lower cylinder pressure force | 20Tons | |

| Lower cylinder pressure stroke | 150MM | |

Advantages of Metal Ceiling Machine

Highly flexible metal ceiling tile production line. KINGREAL CEILING MACHINERY metal ceiling machine can produce a variety types of metal ceiling tiles such as clip-in ceiling tiles, lay-in ceiling tiles, tegular ceiling tiles, etc. By simply replacing the cutting mold, one metal ceiling tile production line can produce both clip in ceiling panel and lay in ceiling panels.

High-speed metal ceiling machine. KINGREAL CEILING MACHINERY metal ceiling tile production line has a fast production speed, from unwinding to discharging (including perforation) The production speed is about 5-6 pieces per minute.

Can be perfectly matched with the metal ceiling tile perforation line. In addition to producing plain metal ceiling tiles, KINGREAL CEILING MACHINERY metal ceiling tile production line can also be equipped with a metal ceiling tile perforation line to meet customers' production needs for half-hole ceiling panels or full-hole ceiling panels.

Can produce metal ceiling panels of different sizes. KINGREAL CEILING MACHINERY metal ceiling machine can produce metal ceiling tiles of regular sizes such as 30x30cm, 60x60cm, 60x120cm, etc. At the same time, if you have special production requirements for metal ceiling board dimensions, you are welcome to send drawings and parameters to KINGREAL CEILING MACHINERY. Engineers will design a personalized metal ceiling tile production line manufacturing plan based on your actual production situation.

Complete Metal Ceiling System

Solution 1: False ceiling channel machine and metal ceiling machine

Matching scheme of metal ceiling tile production line and false ceiling channel machine:

In theory, CD and UD produced by false ceiling channel machine can be spliced with any size and type of metal ceiling panel produced by metal ceiling machine. In the ,metal ceiling system, CD profile is the main load-bearing member, and UD profile is used as peripheral support to guide and fix CD profile. CD and UD are made of high-quality galvanized steel to ensure strength, durability and corrosion resistance, which is perfectly suitable for ceiling structure to form a light and strong support system. |  |

Introduction of false ceiling channel machine:

False ceiling channel machine usually produces 60x27mm CD profile and 28x27mm UD profile with galvanized coil as raw material. Smart touch screen and precision-made roll forming machine ensure the stability, efficiency and finished product accuracy of production. |  |

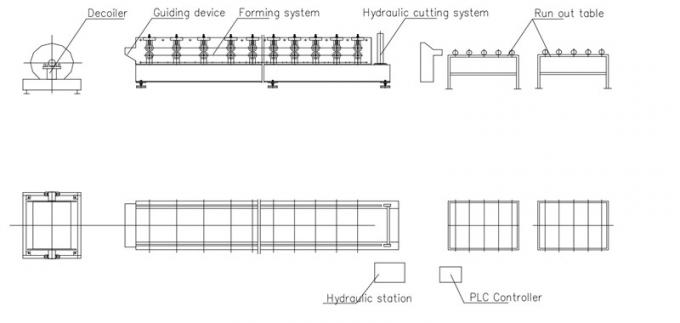

Workflow of false ceiling channel machine:

Decoiler --Main Roll Forming Machine--Cutting Station--Product Table |  |

Parameters of false ceiling channel machine:

| False Ceiling Channel Machine | |

| Material | GI strip |

| Material thickness | 0.3-0.8MM |

| Roller station | 12 |

| Roller material hardness 30-40 HRC | Cr 12 |

Working speed | 50m/min |

Solution 2: Main ceiling channel machine and metal ceiling machine

The matching solution of metal ceiling tile production line and false ceiling channel machine:

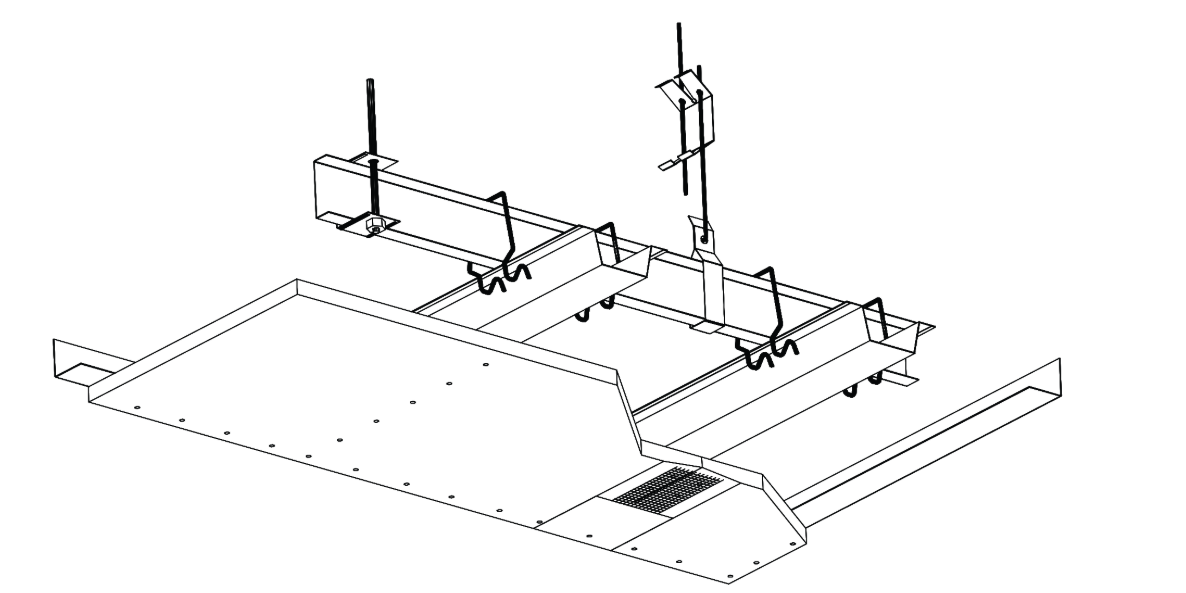

The hat channel produced by the furring channel machine is used as the main support part for fixing the metal ceiling panel in the metal ceiling system. The u channel produced by the u channel machine is used as the main part to support the ceiling part to the suspension system. In the ceiling system, the wall angle produced by the wall angle machine constitutes the perimeter of the suspended ceiling, provides support for the metal ceiling tiles, and hides the joints between the wall and the ceiling, thereby achieving a neat and beautiful finish. |  |

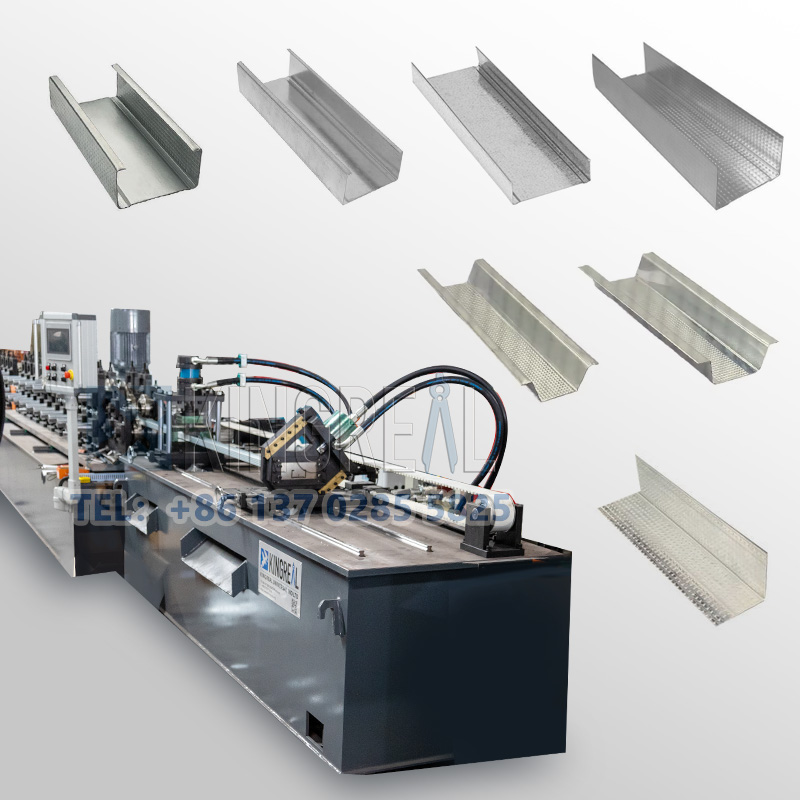

Introduction of false ceiling channel machine:

The main ceiling channel machine consists of three types of machines: u channel machine, wall angle machine, and furring channel machine. Usually, GI steel or PPGI with a thickness of 0.4-1.0mm is used as the metal raw material to produce furring channels, u channel and wall angles of the size required by customers. In order to improve the competitiveness of the finished product, KINGREAL CEILING MACHINERY can provide two solutions to produce finished products with customer brand logos. The first method is to install an inkjet device on the roll forming machine, and the inkjet system prints the customer's required logo on the surface of the finished product while forming. The second method is to engrave the customer's brand logo on the forming roller. When the metal coil is rolled, the two steps of forming and engraving the logo on the surface are completed at the same time. |  |

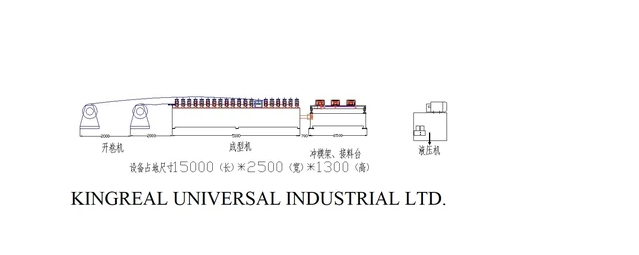

Workflow of false ceiling channel machine:

Hydraulic Decoiler -- Main Roll Forming Machine -- Shearing System -- Product Table |  |

Parameters of main ceiling channel machine:

| Raw material | Gi steel, pre-painted gi steel |

| Product shape | Wall angle, u channel, hat channel |

| Production capacity | 120m/min |

| Electricity requirement | 380v 50 Hz 3 Phases |

| Power consumption | 30KW |

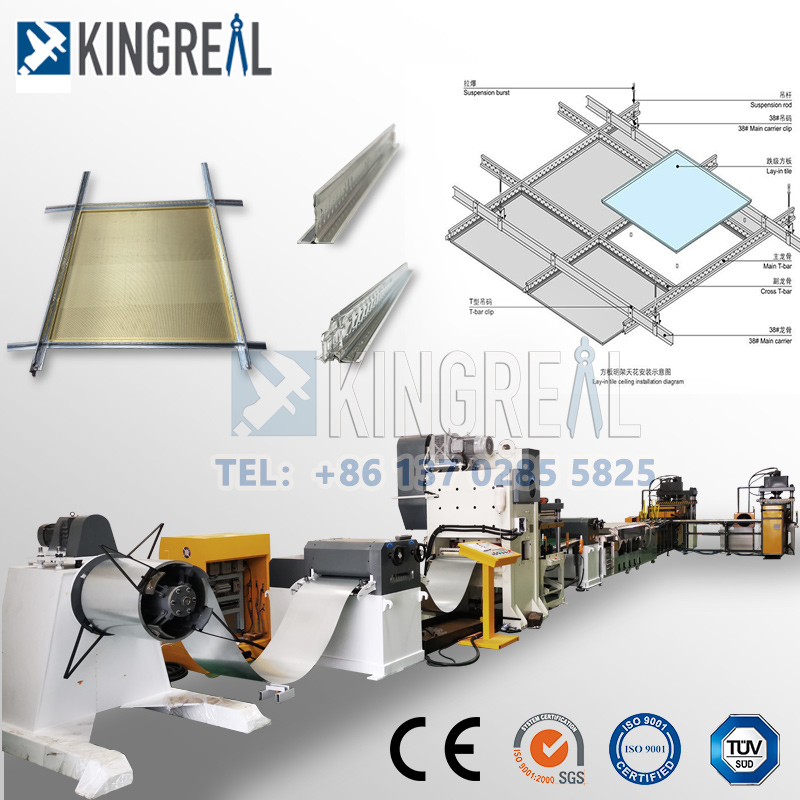

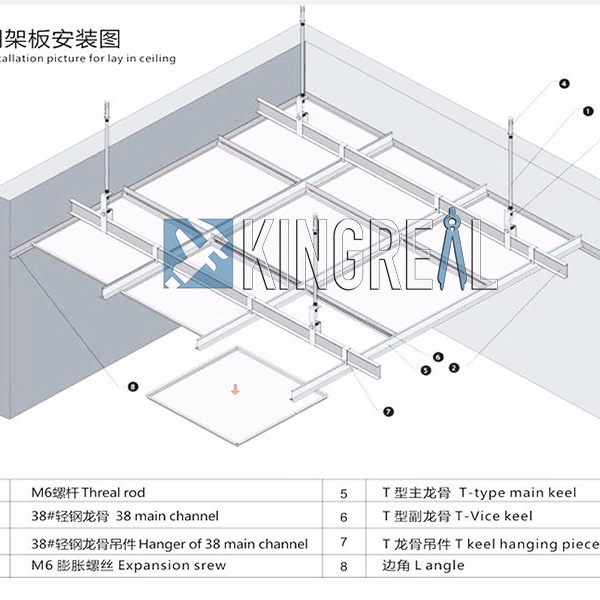

Solution 3: Ceiling t bar machine and lay in ceiling production line

The combination of lay in ceiling production line and ceiling t grid machine:

The main t and cross t produced by the ceiling t bar machine are a frame to support metal ceiling tiles. The main t and cross t are connected to each other to form a stable structure. The lay in ceiling tiles are located inside the grille built by the ceiling t bar, forming a complete, beautiful and practical ceiling system. |  |

Introduction of ceiling t grid machine:

KINGREAL CEILING MACHINERY ceiling t grid machine can produce main t, cross t and wall angle of various sizes, and according to the different needs of customers for usage scenarios and purposes, KINGREAL CEILING MACHINERY can also provide flat ceiling t bar machines, silhouette ceiling t grid machines, FUT t grid machines, and black line ceiling t bar machines. In order to ensure the safety of customers' production and reduce safety hazards, KINGREAL CEILING MACHINERY can equip the ceiling t bar machine with a protective shield. |  |

Workflow of ceiling t bar machine:

Hydraulic Decoiler -- Main Roll Forming Machine -- Punching and shearing station--Product table |  |

Parameters of ceiling t grid machine:

Roller Stands | 18 Sets, 2sets of rollers for alignment (main t) 18 Sets,1sets of rollers for alignment (main t) |

| Roller Material | Cr12 Mold Steel, Average hardness HRC55 |

| Production Speed | 0-33m/min |

| Machine Frame | 20mm thickness base panel, 6mm side panel,45#Steel |

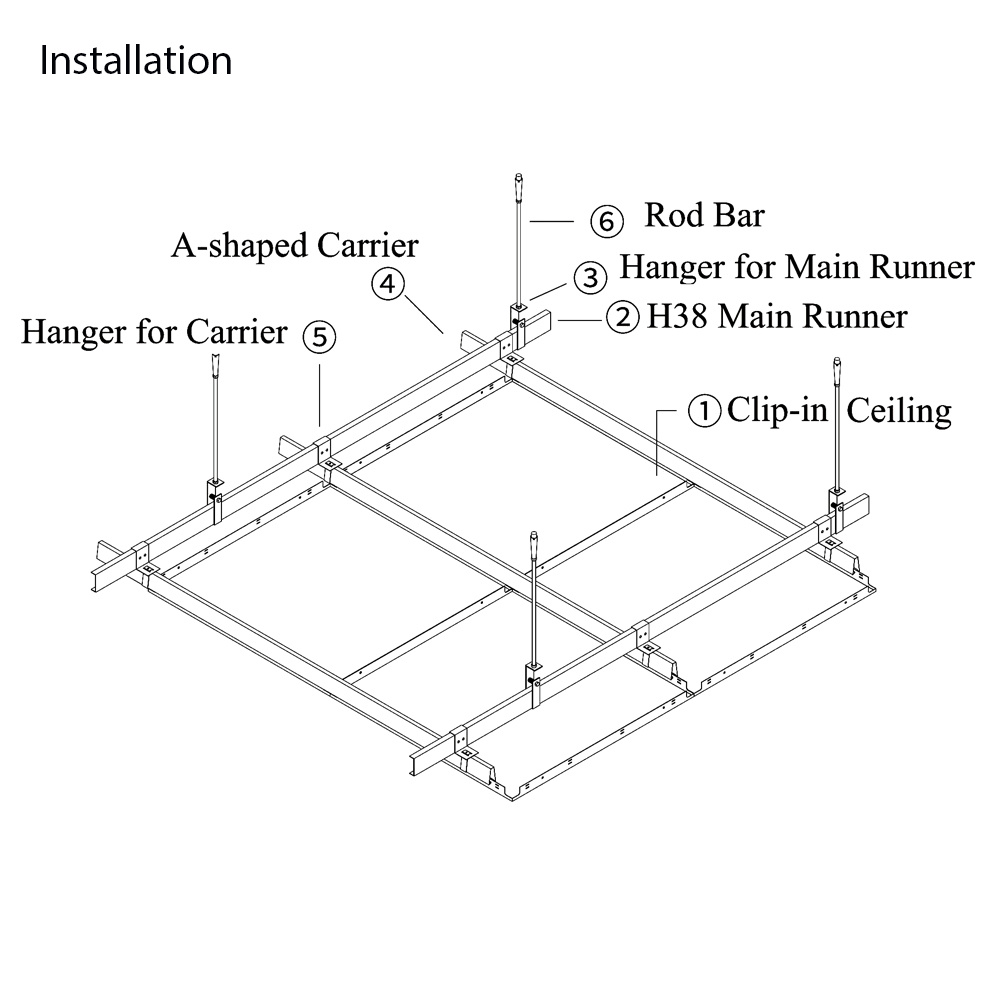

Solution 4: A-type carrier roll forming machines and clip in ceiling machine

Metal ceiling machine and A-type carrier roll forming machine matching solution:

The A-type carrier produced by the A-type carrier roll forming machine is a hidden keel system. When used with the clip in ceiling tile produced by the clip in ceiling production line, it can create a beautiful ceiling surface with hidden design, stable structure and smooth surface. |  |

Introduction to A-type carrier roll forming machine:

This A-type carrier roll forming machine is generally used for metal ceiling panels with large size or large thickness range. For example, the size of a 0.6-0.7 thickness iron ceiling tile is 600X1200mm. This A-type carrier roll forming machine can produce A-type carriers of different sizes, which can be set through the PLC control system. Just enter the required specifications into the operating system with a touch screen, and the whole machine can be adjusted according to the needs. The hydraulic follow shearing station can cut the product length according to the needs. |  |

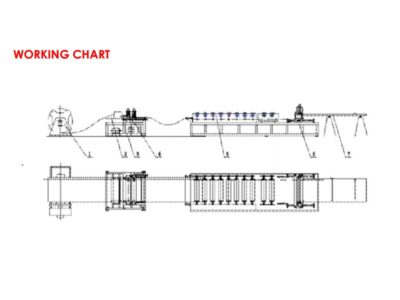

Workflow of A-type carrier roll forming machine:

Decoiler --Roll Forming Machine--Cutting Station |  |

Parameters of A-type carrier roll forming machine:

| Raw materials | galvanized steel strip |

| A-type carrier sizes | According with customer's drawing |

| Maximum forming speed | 30m/min |

| Shearing method | Saw blade shearing with following cutting |

| Roll forming stands | 18 Rollers station |

| Control method | PLC control and touch screen |

| Length detect | Omron encoder |

| Machine power | ~18KW |

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)