Main Channel Making Machine

In order to meet the requirements of different usage scenarios and production material thickness, KINGREAL CEILING MACHINERY provides a variety of efficient Main Channel Making Machines, including CW UW Making Machine and U Channel Machine. U Channel Machines are mainly used to produce false ceiling channels, which are widely used in ceiling supports of buildings, while CW UW Making Machines are mainly used for wall support structures. These two types of Main Channel Making Machines not only improve production efficiency, but also play an important role in the construction industry, helping to carry and separate spaces.

- KINGREAL CEILING MACHINERY

Details

Video About Main Channel Making Machine

Introduction of Main Channel Making Machine

In order to meet the requirements of different usage scenarios and production material thickness, KINGREAL CEILING MACHINERY provides a variety of efficient Main Channel Making Machines, including CW UW Making Machine and U Channel Machine. U Channel Machines are mainly used to produce false ceiling channels, which are widely used in ceiling supports of buildings, while CW UW Making Machines are mainly used for wall support structures. These two types of Main Channel Making Machines not only improve production efficiency, but also play an important role in the construction industry, helping to carry and separate spaces.

The design of the Main Channel Making Machine takes into account different building needs. KINGREAL CEILING MACHINERY Main Channel Making Machine can be customized according to the specific requirements of customers to ensure that various building specifications and standards are met. Whether it is a CW UW Making Machine or an U Channel Machine, KINGREAL CEILING MACHINERY can provide customers with corresponding production Main Channel Making Machine.

|  |

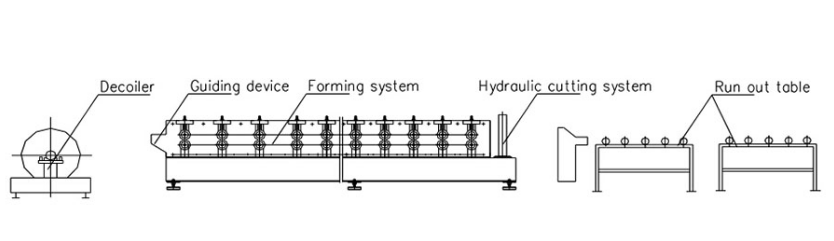

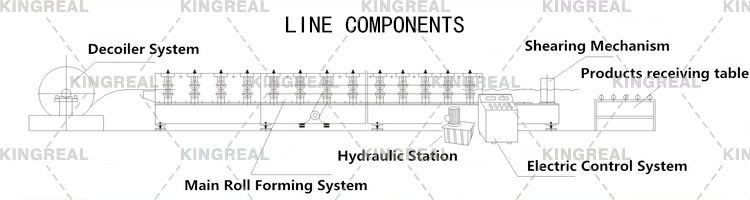

Workflow of Main Channel Making Machine

Hydraulic Decoiler ↓ Main Roll Forming Machine ↓ Fly Shearing System ↓ Product Table |  |

Decoiler ↓ Main Roll Forming Machine ↓ Hydraulic Fly Punching and Shearing System ↓ Product Table |  |

Product Display

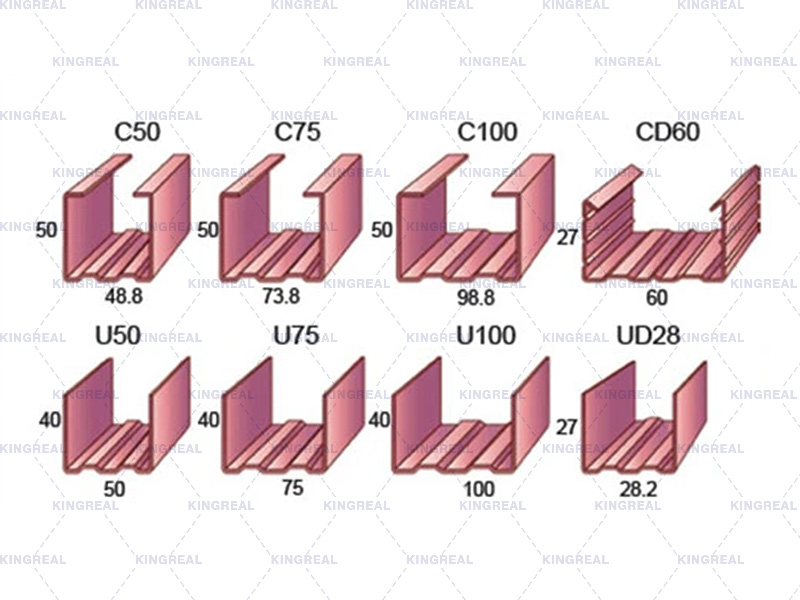

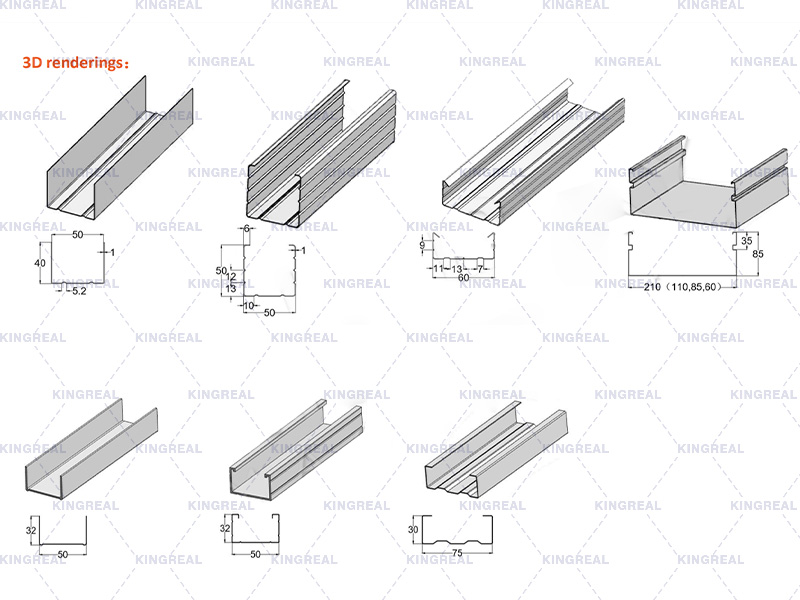

Although CW UW Making Machines and U Channel Machines are widely used in construction projects, they have significant differences in finished product size and use.

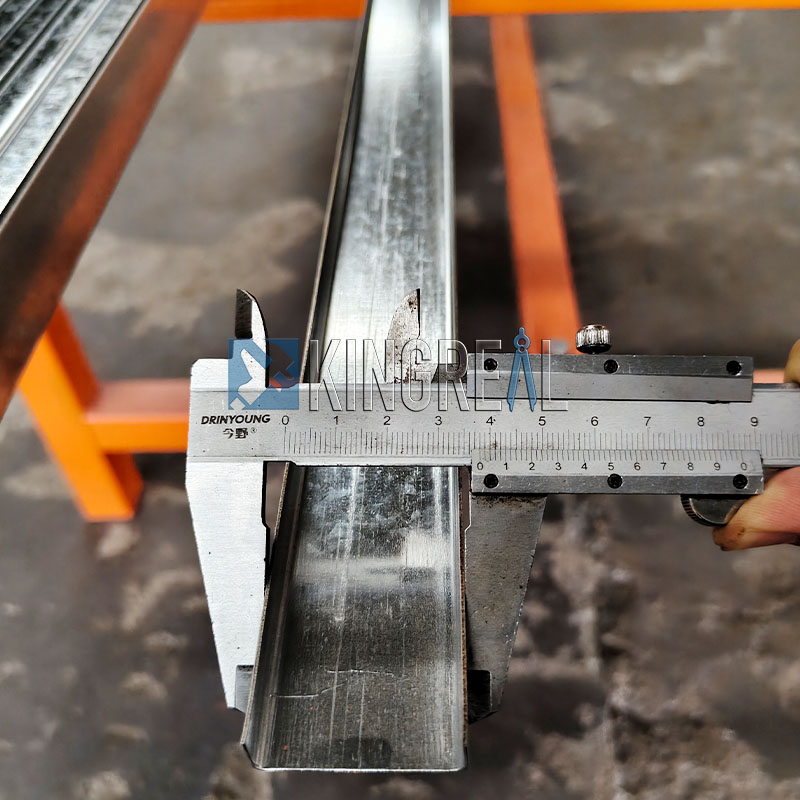

Product Size: CW UW by CW UW Making Machine CW: 50x50x3000mm, 75x50x3000mm, 100x50x3000mm UW: 50x40x3000mm, 75x40x3000mm, 100x40x3000mm CD UD by U Channel Machine CD: 60x27mm UD: 28x27mm Purpose of Main Channel Making Machine: U Channel Machine: Mainly used for ceiling support, often used in combination with spring tee and Clip-in ceiling tiles to provide stable ceiling structure support. CW UW Making Machine: Designed for wall support, it can effectively bear the weight of the wall and provide solid structural support. |  |

|

Advantages of Main Channel Making Machine

Advantages of CW UW Making Machine

(1)Decoiler selection for CW UW Making Machine

KINGREAL CEILING MACHINERY is equipped with two types of decoilers for CW UW Making Machines - single-head decoiler and double-head decoiler. Each of these two types of decoilers has its own unique advantages and can meet different production needs.

● Single-head decoiler for CW UW Making Machine The single-head decoiler is a standard decoiler suitable for general production needs. It has a simple structure, is easy to use, and has low maintenance costs. For small-scale production or start-ups, the single-head decoiler is an ideal choice. It can effectively complete the unwinding task of the material and ensure the smooth progress of the production process. |  |

● Double-head decoiler for CW UW Making Machine The double-head decoiler is a more technologically advanced option, which allows the material to be unwound on the left side while loading on the right side. This design greatly improves production efficiency and ensures the possibility of continuous production. When the material on the left side is exhausted, the operator only needs to turn the decoiler 180° to continue using the material on the right side. This flexible design enables the double-head decoiler to effectively reduce downtime and improve overall production efficiency in a large-scale production environment. |  |

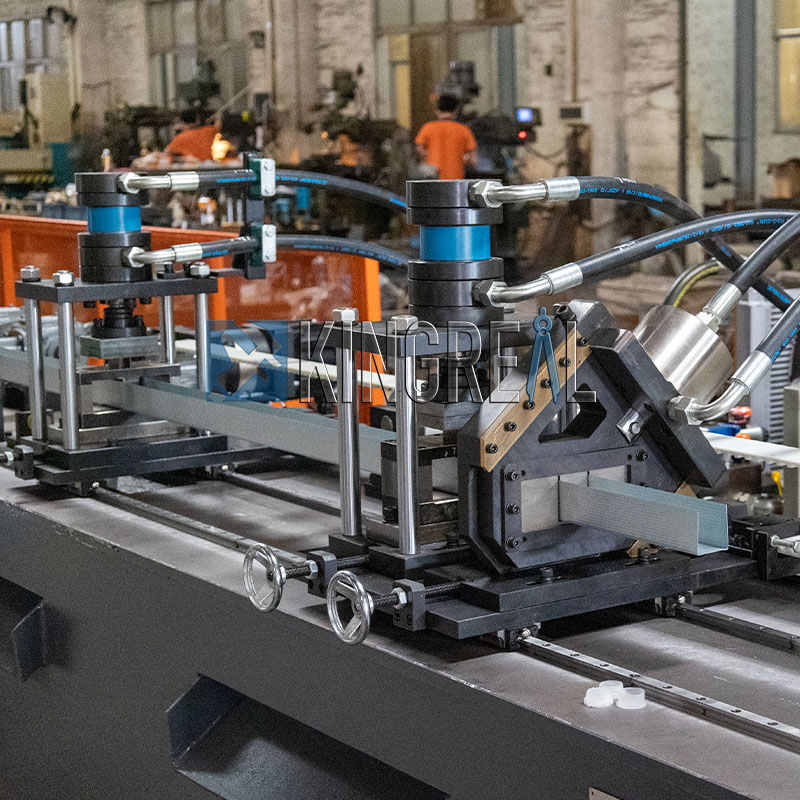

(2)Flying punching and shearing system for CW UW Making Machine Another significant advantage of the CW UW Making Machine is its fly punching and shearing system. By replacing the cutting knife mold, the system allows users to easily produce two different shapes of finished products, CW and UW, on the same machine. More importantly, the roller mold with LOGO can be installed on the punching station to produce finished products with customer brand logo. Customers can customize products according to their needs to improve product competitiveness. |  |

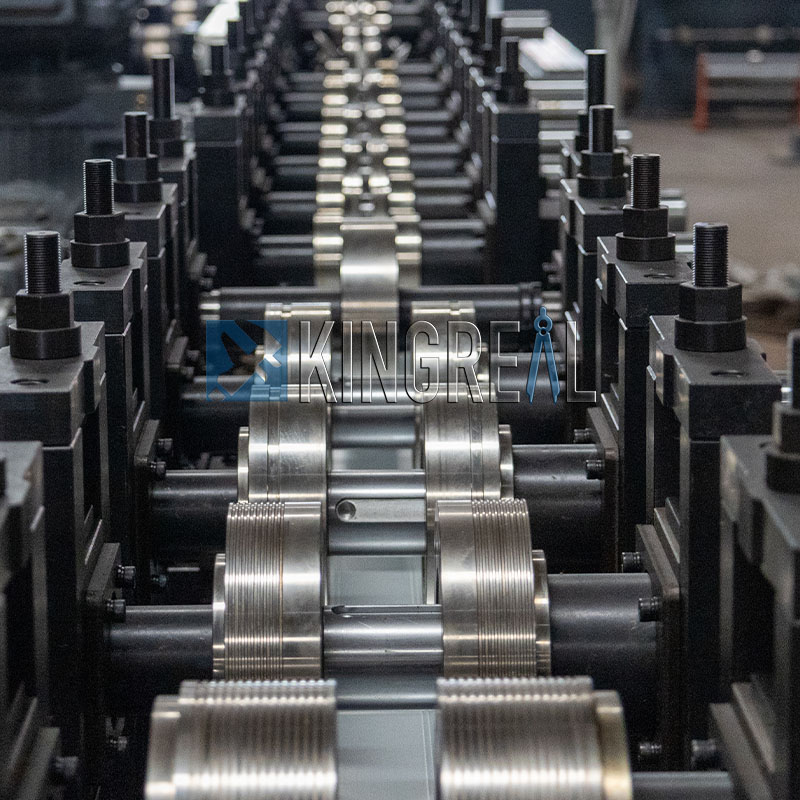

(3)Adjustable width roller set for CW UW Making Machine KINGREAL CEILING MACHINERY roll forming machine is equipped with an adjustable width roller set. Users only need to enter the required finished product parameters on the control panel, and the roll forming machine can automatically adjust the roller width to produce CW or UW of different sizes. This intelligent design not only improves production efficiency, but also greatly reduces the complexity of manual operation. Whether it is small batch production or large-scale production, CW UW Making Machine can be easily switched to quickly respond to changes in market demand. |  |

Advantages of U Channel Machine

(1)High-speed U Channel Machine The production speed of the U Channel Machine is as high as 120 m/ min, which greatly improves production efficiency, especially suitable for the needs of large-scale construction projects. By continuously reducing production time, enterprises can complete more projects in a shorter time, thereby improving overall profitability. |  |

(2)Efficient servo motor for U Channel Machine The U Channel Machine is equipped with a 4.4KW Yaskawa servo motor to ensure the stability and efficiency of the roll forming machine during operation. The introduction of servo motors makes the motion control of the rollers more precise and improves the forming accuracy. This efficient drive system not only improves the consistency of the products, but also reduces the downtime caused by equipment failure, further improving production efficiency. |  |

(3)High-quality components for U Channel Machine The U Channel Machine adopts an advanced electrical system and an intelligent touch screen operating system to ensure the stable operation and automated production of the equipment. Users can easily set and adjust production parameters through the touch screen, which improves the convenience of operation. The intuitive interface design allows operators to quickly get started even if they are beginners, reducing training costs and time. |  |

Quality Assurance

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)