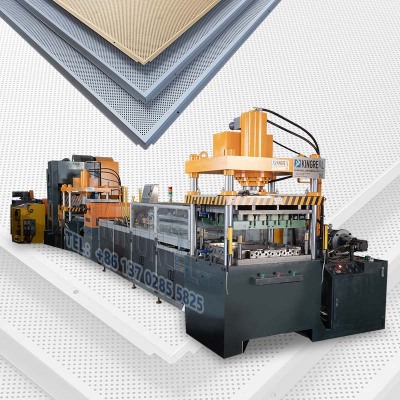

Semi Auto Suspended Ceiling Tiles Production Line

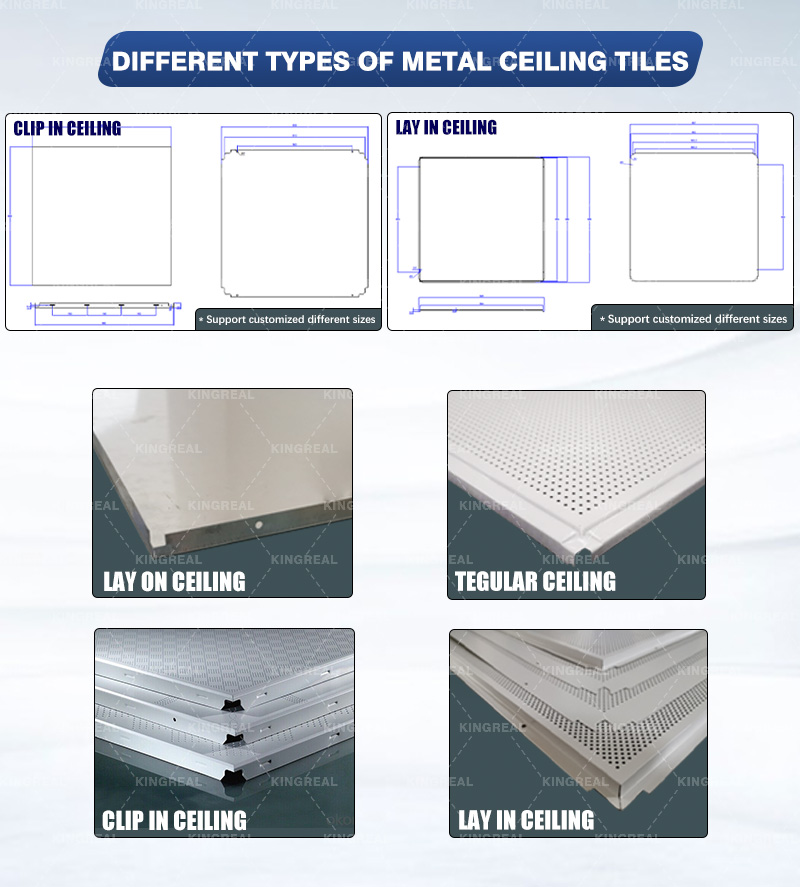

KINGREAL CEILING MACHINERY can provide the Semi Automatic Metal Ceiling Tile Production Line for producing metal ceiling tile of various types, such as clip in metal ceiling tile, lay in metal ceiling tile, tegular metal ceiling tile, etc.

This aluminum ceiling prodution line can produce different sizes, including 300*300mm, 600*600mm, 600*1200mm size metal ceiling tiles through changing the dies.

- KINGREAL CEILING MACHINERY

- China

Details

Video About KINGREAL CEILING MACHINERY Aluminum Ceiling Production Line

Related Project about Semi-auto Metal Ceiling Machine

This Indian customer is a newcomer to the metal ceiling tile manufacturing industry with a small production scale. Therefore, KINGREAL CEILING MACHINERY engineers introduced KINGREAL CEILING MACHINERY's semi-automatic aluminum ceiling production line to the customer based on his drawings and after full communication. The advantage of this semi-auto metal ceiling machine is that the price is reasonable. Although it is not fully automated, the production speed is not slow. If the customer's production scale expands in the future, KINGREAL CEILING MACHINERY can add equipment for the customer to upgrade to a fully automated metal ceiling making machine.

KINGREAL CEILING MACHINERY semi automatic metal ceiling making machine sucessfully exported to India

Description Of Semi Automatic Metal Ceiling Machine

KINGREAL CEILING MACHINERY Semi-automatic metal ceiling making machine is designed to be highly efficient and can produce metal ceiling tiles in various sizes and shapes. This Aluminum Ceiling Production Line are also relatively easy to operate, making it suitable for factories that do not have particularly high production requirements. Additionally, KINGREAL CEILING MACHINERY metal ceiling machine can be customized to meet specific customer requirements, and can be upgraded to fully automatic aluminum ceiling production lines as the business grows.

Advantages Of Semi Automatic Metal Ceiling Machine

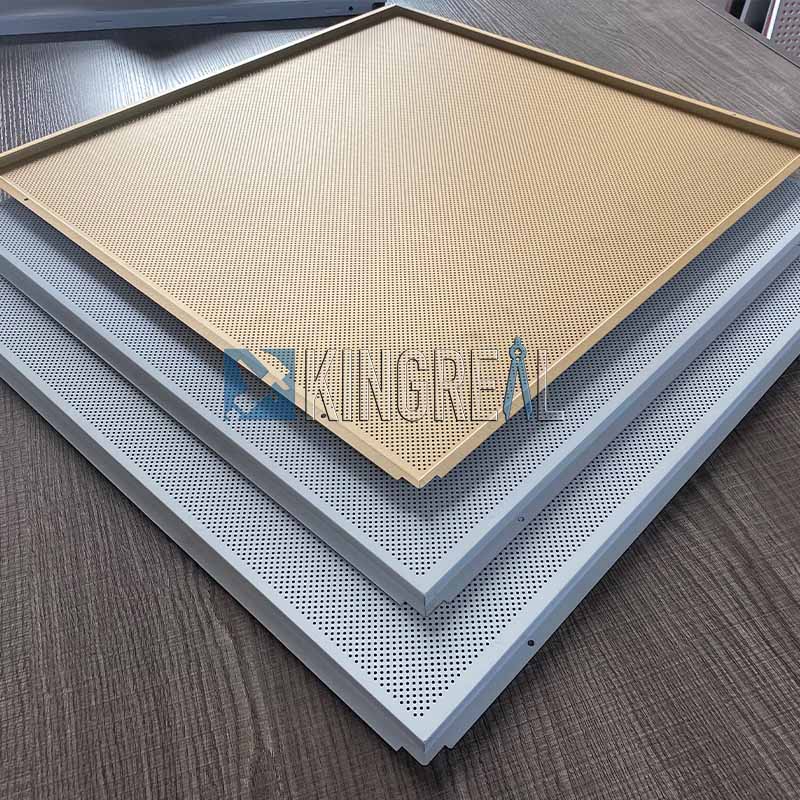

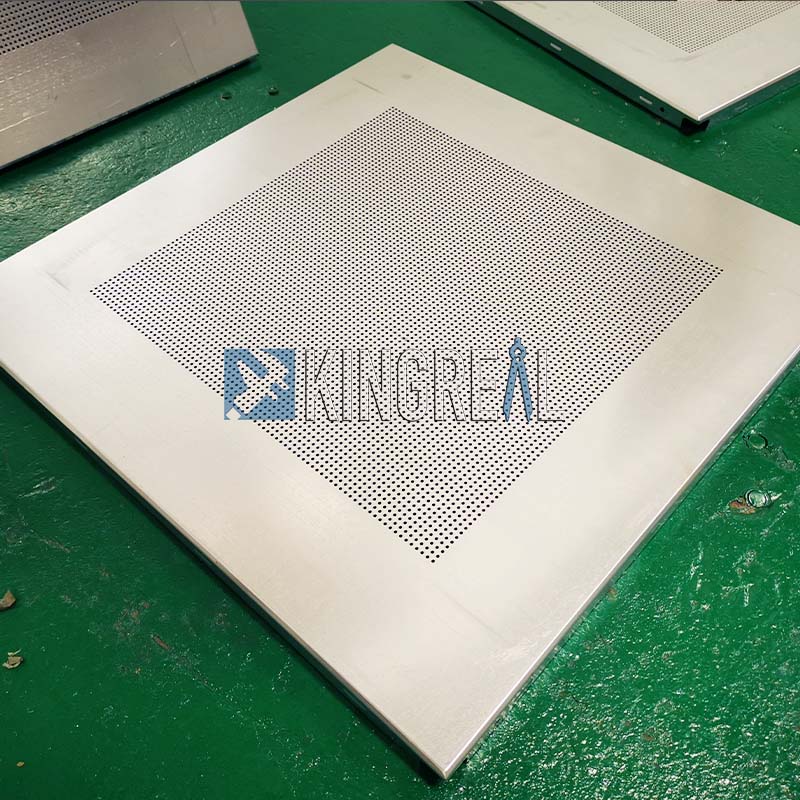

⭐ Production of Different Types of Metal Ceiling Panels

By changing different molds, the semi-automatic metal ceiling machine can flexibly produce various types of metal ceiling panels (such as clip-in metal ceiling tile, lay-in metal ceiling tile, tegular metal ceiling tile, etc.).

Additionally, the aluminum ceiling production line supports manufacturing metal ceiling panels in various sizes (including 30x30 cm, 60x60 cm, and 60x120 cm). This design allows the aluminum ceiling prodution line to adapt to diverse market demands and meet the specific requirements of different engineering projects, achieving efficient and precise production.

⭐ Various Combinations of Metal Ceiling Machine

The semi-automatic metal ceiling making machine can be paired not only with metal ceiling tile perforation lines but also with feeding trolley. This enables a more efficient production process and more flexible operations. By combining these accessories, the aluminum ceiling production line can be adjusted according to different production needs, enhancing both production efficiency and product quality.

⭐ Semi-Automatic Metal Ceiling Machine

Semi automation technology reduces the complexity of manual operations, increases production efficiency, and ensures a fast and stable output.

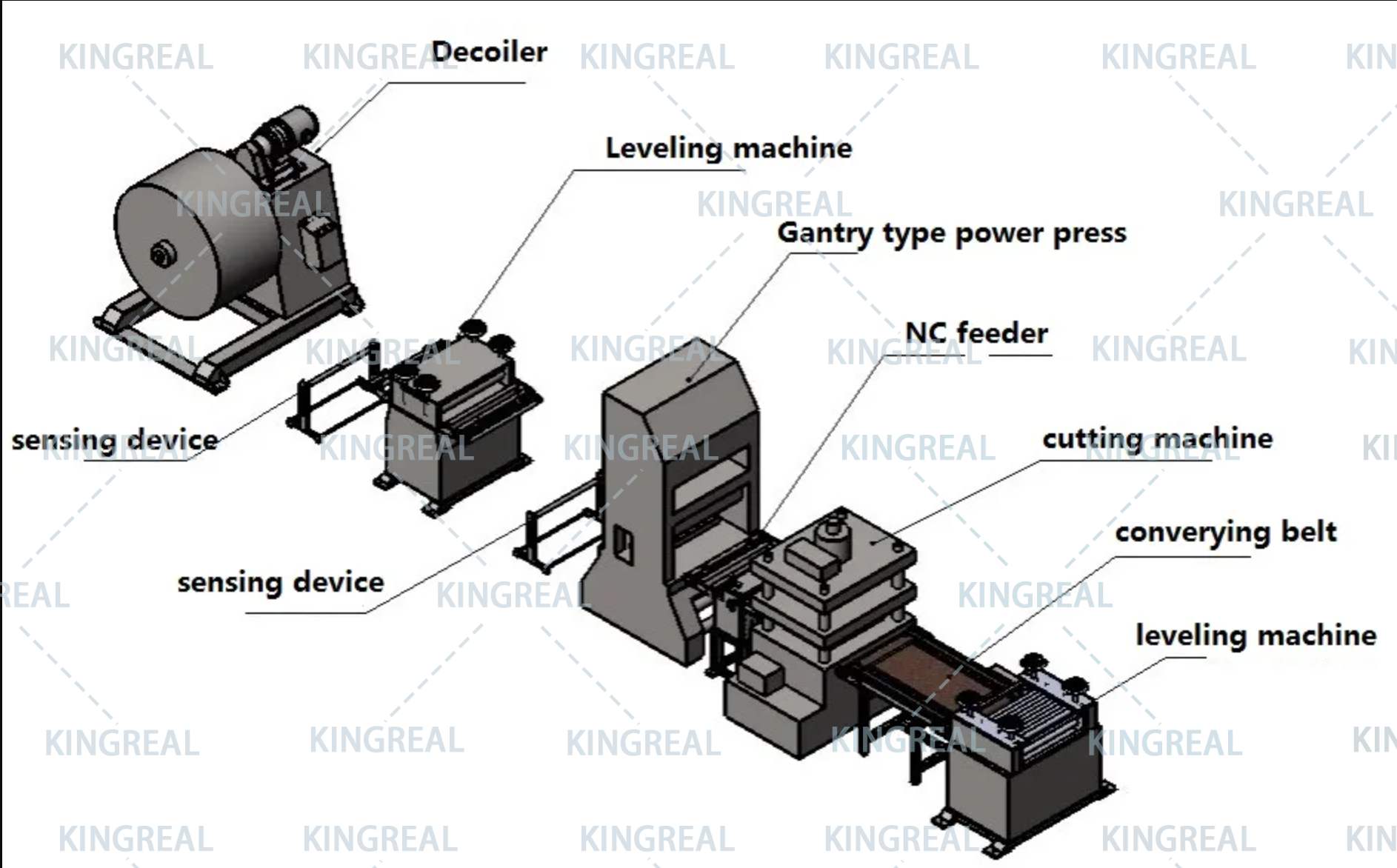

Working Process Of Metal Ceiling Making Machine

Decoiler -- Sensing Device -- Leveling Machine -- Sensing Device -- Gantry Type Power Press -- NC Feeder -- Cutting Machine -- Conveyor Belt -- Leveling Machine

Main Components Of Semi Auto Metal Ceiling Machine

(1) Decoiler for Metal Ceiling Machine

This is the first stage of the aluminum ceiling prodution line where the metal coil is loaded onto the machine for processing.

Specifications of Hydraulic Decoiler

| Width of material | <700 mm |

| Max. Outer diameter | Φ 1200 |

| Maximum load | 5 tons |

| Expansion diameter | Φ 450-530 (Φ 508 adaptable) |

| Expansion | Hydraulic expansion |

| Speed reducer | Cycloid pin |

| Electric motor | Three-phase asynchronous motor,3 KW |

(2) Notching and Shearing Press Machine for Metal Ceiling Making Machine

A notching and shearing press machine is a type of industrial machinery used for cutting and shaping metal sheets or plates. The machine is equipped with a sharp cutting tool, which can be used to create notches, cuts, and other shapes in the metal material.

The notching and shearing press machine typically consists of a sturdy frame, a hydraulic or mechanical power source, and a cutting head with various cutting tools. The cutting head can be moved up and down or from side to side to adjust the cutting position.

Specifications of Notching and Shearing Press Machine

| Cylinder pressure force | 60 tons |

| Cylinder stroke | 200 mm |

| Distance between movable crossbeam and worktable | 200 mm (minimum) 400 mm (maximum) |

| Ground clearance of worktable | 850 mm |

| Machine size (W, L, H) | 2100 mm x 1100 mm x 2000 mm |

| Power consumption | 5.5 KW |

| Weight | ~ 4.3 tons |

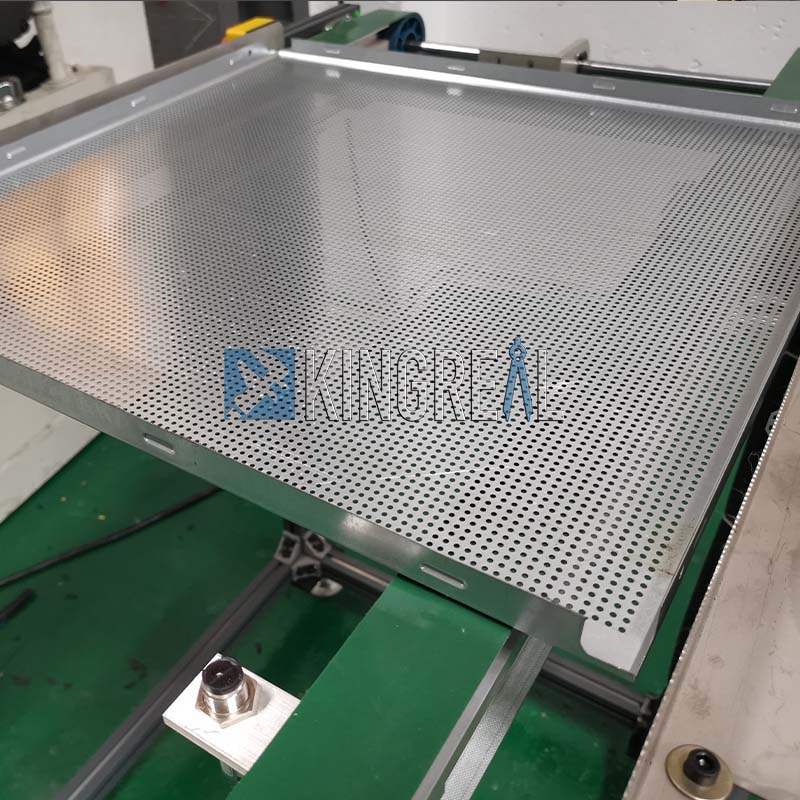

(3) High-speed Punch Press Machine for Metal Ceiling Making Machine

A high-speed punch press machine is a type of mechanical equipment used for punching holes or shapes into metal sheets that will be used for metal ceiling tile applications. This machine utilizes a high-speed punching mechanism that operates at a rapid pace, allowing it to create holes or shapes quickly and efficiently.

KINGREAL CEILING MACHINERY Gantry Press Machine can reach 200SPM perforation speed with a 125Ton powerful press machine, which can produce Lay-in metal ceiling tile and Clip-in metal ceiling tile at the same time.

Specifications of High-speed Punch Press Machine

| Output pressure force | 125 tons |

| Punching stroke | 20 mm |

| Aperture of holes | Φ 2.5 |

| Adjustable thickness | 10 mm |

| Punching pierce | 100 - 150 times / min |

| Adjust range of enclosed height | 50 mm |

| Size of wafer stage | 1000 mm x 680 mm |

Different Metal Ceiling Tile Production Line Solution

KINGREAL CEILING MACHINERY can provide customers with different metal ceiling machine manufacturing solutions according to customer drawings and actual needs. KINGREAL CEILING MACHINERY's metal ceiling making machine can produce most types of metal ceiling tiles on the market. Including but not limited to 30x30cm, 60x60cm, 60x120cm and other sizes and clip in metal ceiling tile, lay in metal ceiling tile, tegular metal ceiling tile and other types.

Why Choose KINGREAL CEILING MACHINERY?

● Mature technical support

KINGREAL CEILING MACHINERY is skilled in fully automatic process and precision forming processes. The metal ceiling machine produced by KINGREAL CEILING MACHINERY meets the needs of rapid production while maintaining consistent quality and accuracy.

● Have rich experience

KINGREAL CEILING MACHINERY has a professional technical team, KINGREAL CEILING MACHINERY has a professional technical team, from drawing design to machine manufacturing has more than 25 years of relevant experience. As a professional manufacturer of metal ceiling machine manufacturing machinery, KINGREAL CEILING MACHINERY has successfully customized metal ceiling tile production lines to meet customers' needs in many countries, including Turkey, UAE, Russia, India, etc.

KINGREAL CEILING MACHINERY Factory

To integrate R&D, KINGREAL CEILING MACHINERY has established our own factory, located in Foshan, Guangdong. In addition to maintaining close contact online, many of KINGREAL CEILING MACHINERY's customers also choose to visit KINGREAL CEILING MACHINERY factory to observe the production of machines and communicate with us face to face. KINGREAL CEILING MACHINERY is looking forward to reaching long-term and stable relationships with customers around the world with KINGREAL CEILING MACHINERY professional capability and consistent level of service!

Customer Visit

KINGREAL CEILING MACHINERY warmly welcomes customers from all over the world to visit our factory in China. Please do not hesitate to contact us immediately if you need any assistance.

Iranian Customer in KINGREAL CEILING MACHINERY Factory

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)