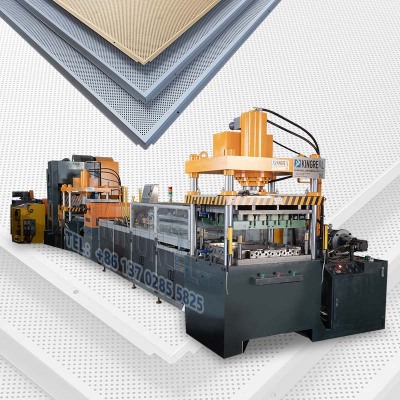

Metal Ceiling Notching And Shearing Press Machine

KINGREAL CEILING MACHINERY can provide a whole solution of metal ceiling tile production line, which includes the sheet metal notchers and shearing press machine. This angle notching machine can cut all four corners in one step, reducing waste and saving costs. And all the other ceiling press equipment can be manufactured by KINGREAL CEILING MACHINERY, welcome to contact us.

- KINGREAL CEILING MACHINERY

- China

Details

Video About High Speed Metal Notching and Shearing Press Machine

Description of Notching and Shearing Press Machine

KINGREAL CEILING MACHINERY Sheet Metal Notching and Shearing Press Machine (corner cut) is a mechanical device used to cut metal ceiling tiles. It usually consists of an electric motor, cutting tool and control system. The corner cutting machine can cut at different angles, allowing the metal ceiling tile to be adapted to different architectural structures and design requirements.

This notching and shearing press machine is an important component in the metal ceiling tile production line. By replacing different molds, different types of metal ceiling tiles can be produced.

And these angle notching machines are commonly used in the construction and decorative industries for making metal ceiling tiles, walls and other metal decorative materials.

Parameter of Metal Notching and Shearing Press Machine

| Technical Parameters | Detailed Information |

Material thicknes | 0.3-0.4 mm (GI Steel) / 0.5-0.6 mm (Aluminum) |

Cylinder pressur | 60 TONS |

Cylinder strok | 200 MM |

| Producible ceiling types | Clip-in, lay-in T24, lay-in T15 (mould change required) |

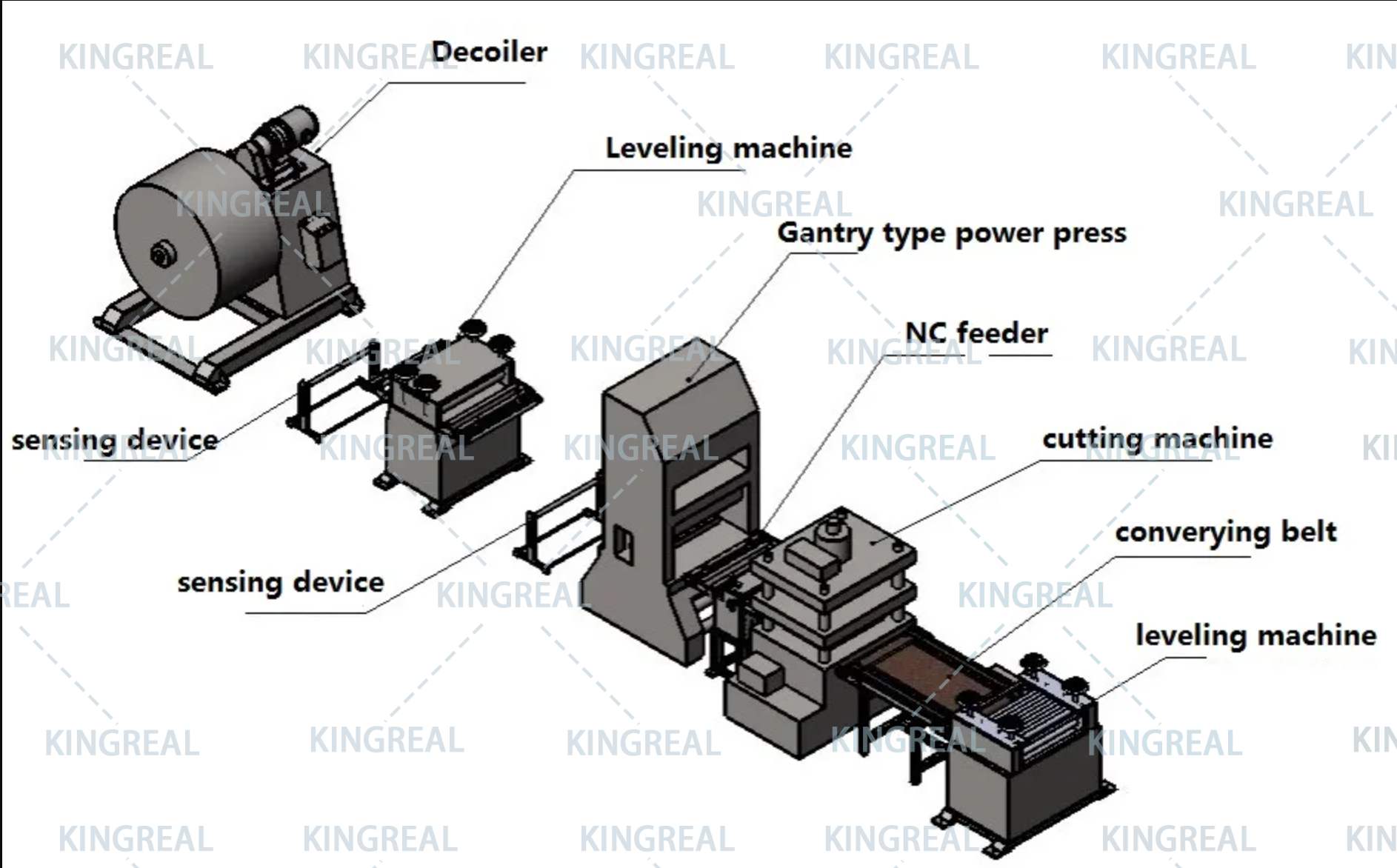

Working Process of Metal Ceiling Tile Production Line

Hydraulic Decoiler -- Precision Straightener -- Punching Machine -- Servo Feeding Machine -- Notching And Shearing Press-2nd Precision Straightener--Flipping machine-- Automatic tiles feeding machine--Auto Bending Forming Machine

Features of Metal N

otching and Shearing Press Machine

1. Improve Production efficiency

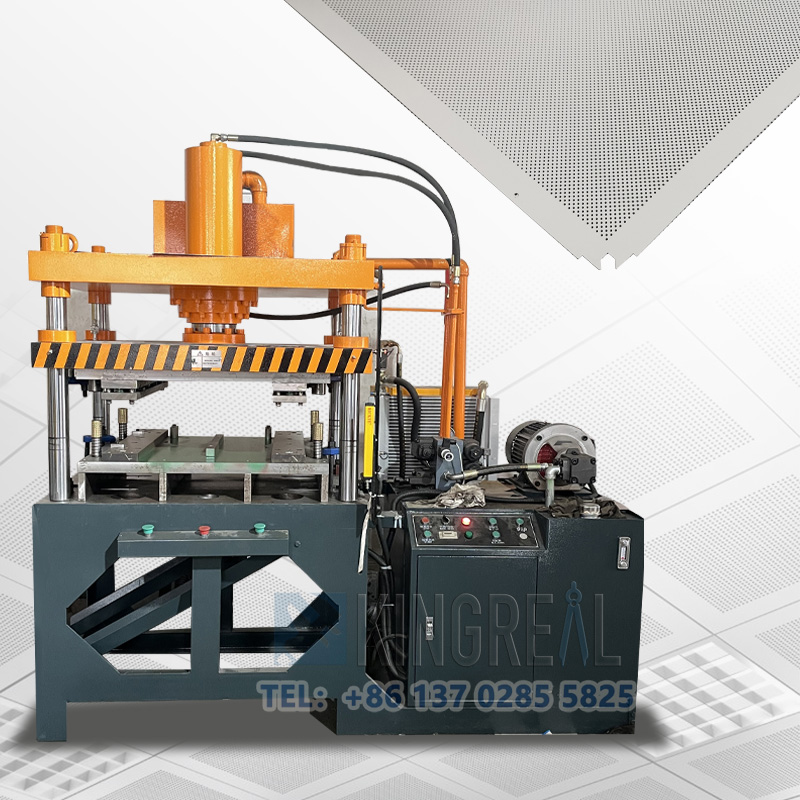

Hydraulic notching and shearing press machines can quickly and accurately complete the cutting of metal ceiling tiles, greatly improving production efficiency. Compared with manual cutting, notching and shearing press machine can complete the task more quickly, saving human resources and time costs.

2. Improve Metal Ceiling Tile Quality

Metal Ceiling Notching and Shearing Press Machine can ensure the accurate cutting angle and size through precise cutting technology, avoiding the errors and unevenness that may occur in manual cutting, thus improving the quality and consistency of the product. The maximum cylinder pressure of the metal notching and shearing press machine is 60 tons, and the cylinder stroke is 200 mm, which further ensures the accuracy and stability of the cutting. In addition, the metal notching and shearing press machine can be equipped with a cooling fan to effectively prevent the machine from overheating during the production process.

3. Improve the automation level

As a part of the metal ceiling tile production line, the sheet metal notching and shearing press machine can realize auto operation and linkage with other equipment, which improves the automation level of the whole metal ceiling tile production line, and further improves the production efficiency and product quality. By replacing different molds, the metal notching and shearing press machine can produce a variety of types of metal ceiling tiles, including clip in ceiling tiles, lay in ceiling tiles(T24, T15), increasing production flexibility.

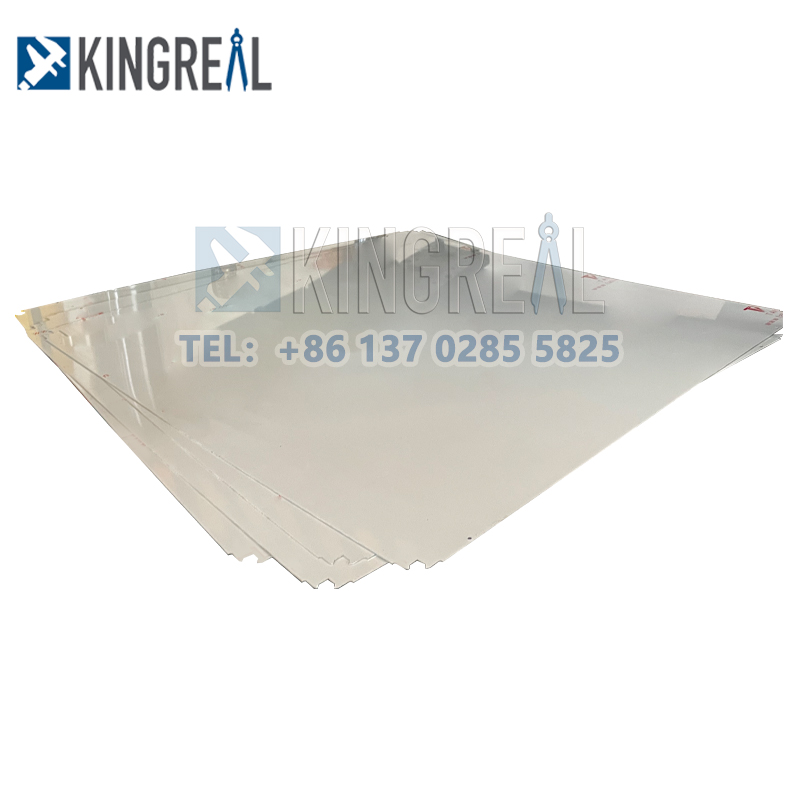

Final Product

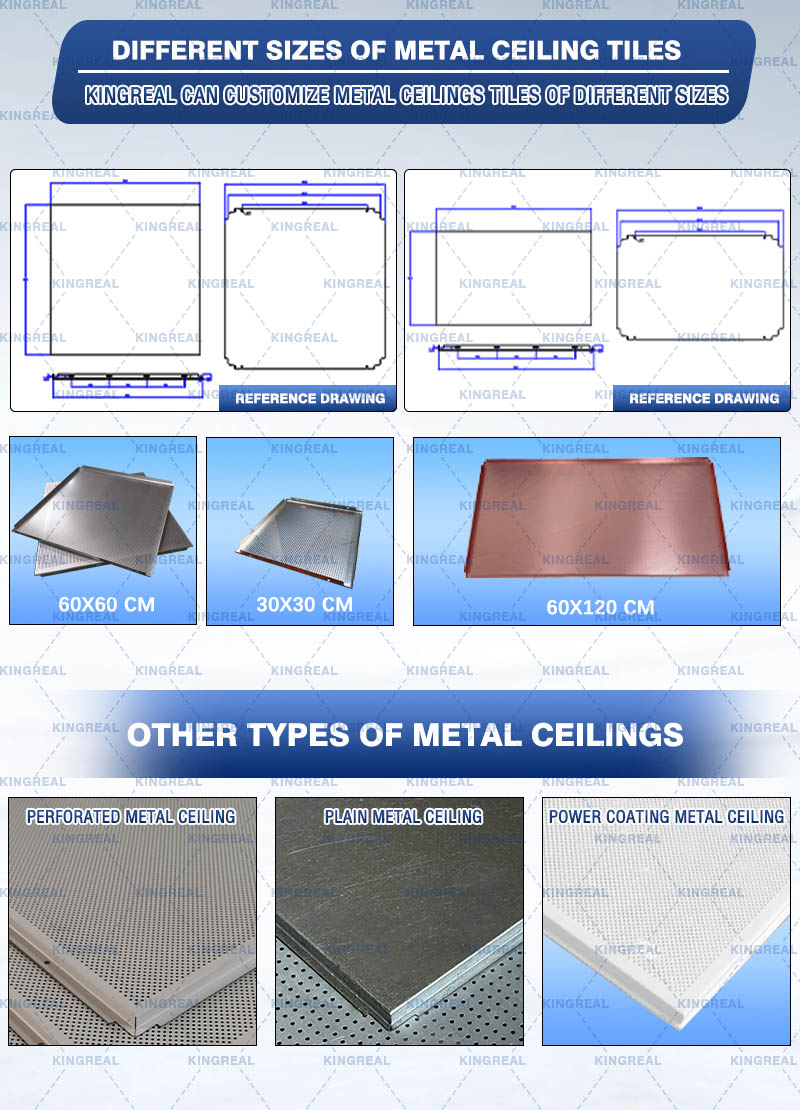

KINGREAL CEILING MACHINERY sheet metal notching and shearing press machine can be used to process different metal materials, such as aluminum and iron. It can accurately cut metal ceiling tiles of different sizes according to the specific needs of customers, including 30x30cm, 60x60cm, 60x120cm and other specifications. The sheet metal notching and shearing press machine is easy to operate. Users only need to enter the required size and cutting parameters, and the equipment will automatically cut. This not only improves production efficiency, but also reduces the possibility of human error and ensures the cutting quality of each metal ceiling tile.

(All These Different Type Metal Ceiling Tile Can Be Produced)

KINGREAL CEILING MACHINERY Technical Team

KINGREAL CEILING MACHINERY is not only integrating R&D, having our own technical team and factory, but also having many years of experience in the design and manufacture of Suspended Ceiling Making Machines. KINGREAL CEILING MACHINERY has successfully customized metal ceiling tile production lines to meet the needs of customers in many countries, including Turkey, the United Arab Emirates, Russia, India and so on.

Services are always highly considered by us, in addition to establishing a complete remote service system, localized after-sales service is also what KINGREAL CEILING MACHINERY has been insisting on doing. The global localization service point is under construction. At present, KINGREAL CEILING MACHINERY has successfully transported the machine production to all over the world, including the United Arab Emirates, India, Russia, Saudi Arabia, Egypt, Pakistan and other countries.

Quality Insurance

KINGREAL CEILING MACHINERY has passed ISO9000 certification and has the ability of ISO9000 quality system management. After you order, KINGREAL CEILING MACHINERY technical team will test the machine in an effort to ensure every mechanical and electrical part is in perfect condition.

KINGREAL CEILING MACHINERY's Projects

KINGREAL CEILING MACHINERY is a professional suspended ceiling machine manufacturing supplier, providing customers with different types of machines, including but not limited to:

Metal ceiling tile production line

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)