Sheet Metal Cleaning Machine

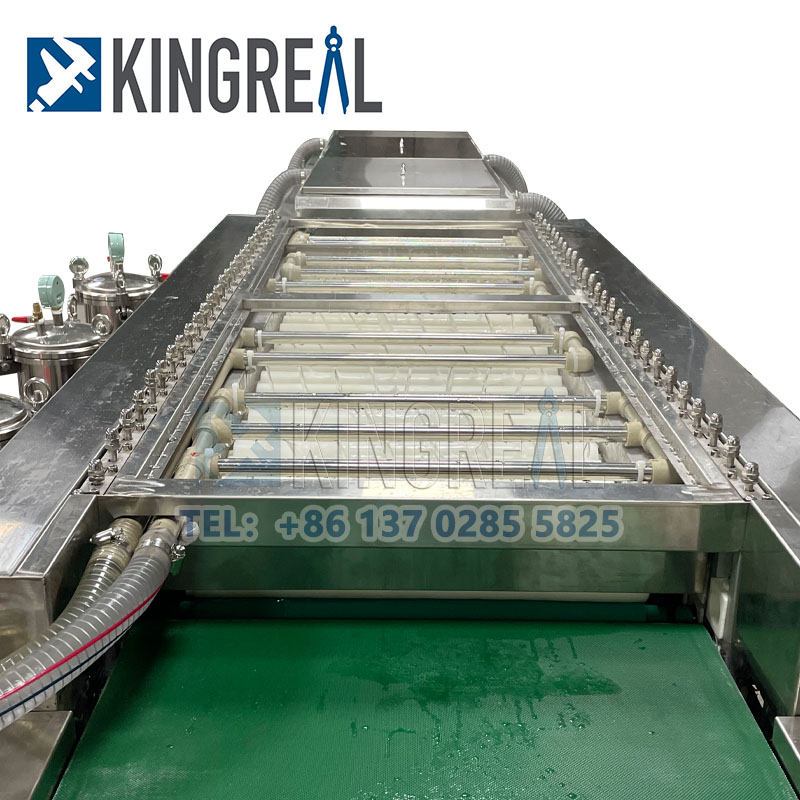

KINGREAL CEILING MACHINERY sheet metal cleaning machine is designed for cleaning a variety of metal materials, including stainless steel, aluminum, mirror stainless steel, and galvanized steel. This metal cleaning machine quickly and effectively removes oil, dust, and other stains from metal surfaces, helping to maintain the cleanliness of the metal surface and ensure the quality of subsequent processing.

- KINGREAL CEILING MACHINERY

- China

Details

Video About Sheet Metal Cleaning Machine

Description of Sheet Metal Cleaning Machine

KINGREAL CEILING MACHINERY sheet metal cleaning machine is designed for cleaning a variety of metal materials, including stainless steel, aluminum, mirror stainless steel, and galvanized steel. This metal cleaning machine quickly and effectively removes oil, dust, and other stains from metal surfaces, helping to maintain the cleanliness of the metal surface and ensure the quality of subsequent processing.

KINGREAL CEILING MACHINERY metal cleaning machine can handle big metal sheets with a maximum cleaning width of 1600mm.Flexibly adapting to different sheet sizes, there is no minimum cleaning length restriction.

Meeting the cleaning needs of metal items of several thicknesses, the cleaning thickness range may be modified. Moreover, the sheet metal cleaning machine's cleaning speed ranges from 0-7m/min, therefore clients may flexibly select the best cleaning speed depending on their real manufacturing circumstances.

The KINGREAL CEILING MACHINERY metal cleaning machine not only provides rapid cleaning capabilities, but also features fully automated, high speed, and low energy consumption.

Workflow of Metal Cleaning Machine

Leveling (optional) ---- Feeding ---- Cleaning ---- Drying ---- Oiling (optional) ---- Discharging ---- Automatic Stacking (optional)

Working Principle of Sheet Metal Cleaning Machine

The metal cleaning machine's workflow primarily involves the following six steps:

-Sheet Input: The metal sheets to be cleaned are automatically fed into the sheet metal cleaning machine via a feed system.

-Cleaning with Water and Detergent: The cleaning fluid is selected based on the metal material and the nature of the contaminants. The detergent is pumped to the spray system to ensure comprehensive coverage and effective decontamination.

-Pure Water Cleaning and Rinse: After cleaning, rinse with purified or deionized water to remove residual detergent and prevent secondary contamination.

-Dehydration: High-speed roller brushes and absorbent cotton absorb water to ensure a moisture-free surface.

-Drying: In a drying oven, high-temperature, strong airflow from a centrifugal fan and heating tubes rapidly removes moisture from the sheet surface. The temperature can be adjusted up to 100°C.

-Finished Product Output: The cleaned metal sheets are automatically output, completing the entire cleaning process.

Key Components of Metal Cleaning Machine

(1)Cleaning section for sheet metal cleaning machine The metal cleaning machine's cleaning section utilizes a combination of white sponges, green rubber rollers, and black bristle brushes to ensure thorough cleaning of both the front and back of metal plates. The sheet metal cleaning machine sprays cleaning solution with even pressure to every corner, guaranteeing complete cleanliness, combined with a very effective stainless steel water pipe spray system. Apart from improving cleaning performance, this design lengthens the lifespan of the equipment. (2)Water tank for metal cleaning machine The water tank is a crucial component of the sheet metal cleaning machine. Utilizing 304 stainless steel guarantees durability and corrosion resistance in KINGREAL CEILING MACHINERY metal cleaning machine.

With a capacity of 500L, each tank is fitted with a heating element able to heat water to 60°C, so satisfying the needs of several cleaning procedures.

Moreover, for simple upkeep and cleaning, a drain outlet is found at the bottom of the water tank, so guaranteeing the sheet metal cleaning machine is always in perfect functioning order. |  |

(3)Drying oven for metal cleaning machine For quick drying, the drying oven has a high-efficiency centrifugal fan and thermostat. The sheet metal cleaning machine rapidly removes moisture from the plates' surface following cleaning, and the adjustable temperature range guarantees the plates won't be harmed during the drying process. The design of the drying oven speeds production cycles, increases production efficiency, and simplifies the whole cleaning procedure. |  |

(4)Operation panel for metal cleaning machine The KINGREAL CEILING MACHINERY sheet metal cleaning machine guarantees the wash solution retains the best temperature by means of a simple operation panel and an sophisticated temperature control system that continuously monitors water temperature. This function makes it simple for operators to manage the washer's action, so increasing convenience and safety.

(5)Automatic feeder machine&automatic stacking machine for sheet metal cleaning machine Significantly increasing production efficiency, the KINGREAL CEILING MACHINERY metal cleaning machine also has an automatic feeder machine&automatic stacking machine. This highly automated layout guarantees a stable and consistent production process while lowering labor costs and manual intervention. The metal cleaning machine's clever operating system ensures precise and effective production, therefore fulfilling client expectations for efficiency and accuracy. |  |

Advantages of Sheet Metal Cleaning Machine

(1)Diverse cleaning methods for metal cleaning machine

KINGREAL CEILING MACHINERY sheet metal cleaning machines support a variety of cleaning methods, including using normal water, hot water, or cleaning agent, detergent soaps, etc.

This varied cleaning process lets the metal cleaning machine nimbly satisfy the cleaning requirements of many metal materials.Whether it's aluminum, galvanized steel, or stainless steel, the sheet metal cleaning machine can choose the most suitable cleaning agent depending on the characteristics of the material and pollutants, therefore satisfying each client's particular cleaning demands.

(2)Efficient detergent utilization for metal cleaning machine

KINGREAL CEILING MACHINERY sheet metal cleaning machines provide customers with strong cost control. Usually, 500–1,000 L of detergent lasts 2–3 days; the particular frequency of use may be changed depending on manufacturing circumstances.

Moreover, the metal cleaning machine's improved cleaning method reduces detergent waste, therefore guaranteeing environmental preservation as well as financial efficiency.

(3)Low water consumption for sheet metal cleaning machine

KINGREAL CEILING MACHINERY metal cleaning machines have low water consumption. Typically, 4000L of water lasts 5-7 days, significantly improving water efficiency. This sheet metal cleaning machine reduces water bills and unnecessary water waste, thereby saving energy and reducing emissions.

Compatible with Various Metal Ceiling Tile Production Line

Full Automatic Metal Ceiling Tile Production Line

Semi-automatic Metal Ceiling Tile Production Line

300x300mm Metal Ceiling Tile Production Line

600x600mm Metal Ceiling Tile Production Line

600x1200mm Metal Ceiling Tile Production Line

Clip in Metal Ceiling Tile Production Line

Lay in Metal Ceiling Tile Production Line

Usage Precautions of Sheet Metal Cleaning Machine

(1)Setting of Equipment and Commissioning

Environmental Needs: Away from direct sunshine, the metal cleaning machine should be set in a well-ventilated, dry, stable environment.

Make sure the power voltage meets the requirements of the sheet metal cleaning machine, the water supply is clean and free of pollutants, and the water pressure meets the demands of the equipment.

(2)Preparation for Pre-Operative Procedures

Make sure the washing solution satisfies all requirements and is adequate.

Regular pipeline inspection searches for obstructions guarantees free flow.

(3)Operational safety precautions

Choose the right cleaning method depending on your needs to guarantee efficient cleaning.

Quickly dispose of any waste liquid to prevent environmental contamination or equipment failure.

(4)Maintenance Following an Operation

Check metal cleaning machine after use and keep track of usage for maintenance reasons.

(5)Safety Precautions

Chemical Safety and Power Supply: Operators should wear protective glasses and gloves to avoid chemical contact. Ensure the power supply is properly connected.

(6)Regular Maintenance and Attention

Regular calibration and inspection guarantee correct sheet metal cleaning machine function.

(7)Training and Operational Manuals

New operators need instruction to become acquainted with the operating guidelines of the gear and guarantee safe and effective application.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)