Wall Siding Panel Machine

The wall siding panel machine is a special equipment designed for the production of metal wall cladding panels in the construction industry. It is usually used to process metal raw materials with a thickness of 0.4 mm to 0.7 mm, such as cold-rolled steel, galvanized steel, aluminum, copper, stainless steel and zinc.

- KINGREAL CEILING MACHINERY

Details

Video About Wall Siding Panel Machine

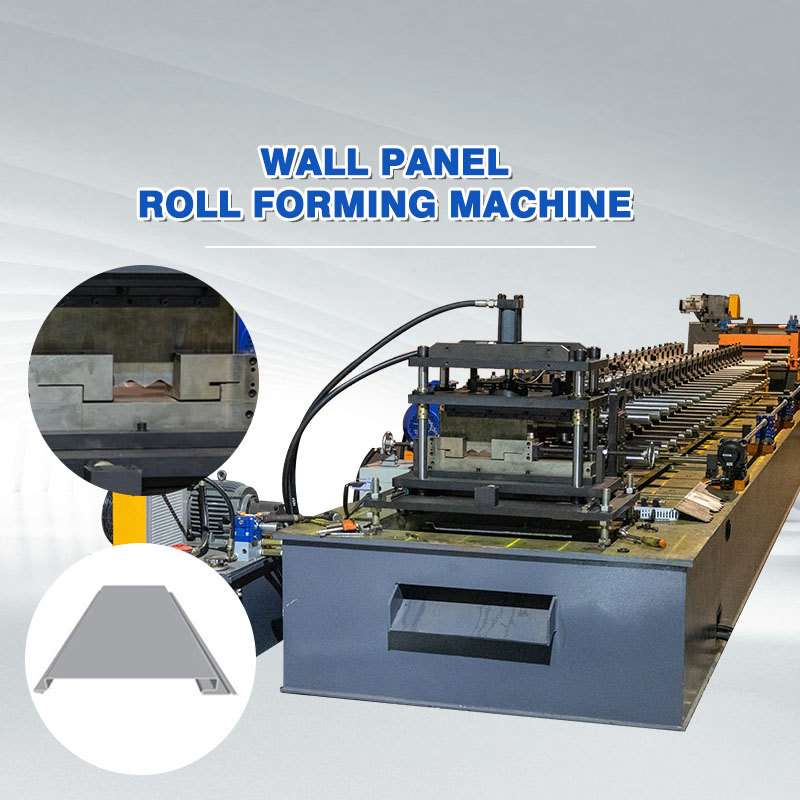

Introduction to Wall Siding Panel Machine

The wall siding panel machine is a special equipment designed for the production of metal wall cladding panels in the construction industry. It is usually used to process metal raw materials with a thickness of 0.4 mm to 0.7 mm, such as cold-rolled steel, galvanized steel, aluminum, copper, stainless steel and zinc. KINGREAL CEILING MACHINERY metal wall cladding panel machine has a sturdy frame and guide column bearings, which can achieve precise forming and has a production speed of 20m/min. Users can freely adjust the production speed according to actual needs.

Each wall siding panel machine adopts a PLC control system, and the operator can easily set the required production length and quantity, and the metal wall cladding panel machine will automatically produce according to the set parameters. This design makes the wall siding panel machine not only efficient, but also extremely flexible, able to meet diverse market needs. The wall panels produced by the wall siding panel machine are widely used in the exterior walls of commercial buildings, office spaces, medical places, industrial buildings and other places. |  |

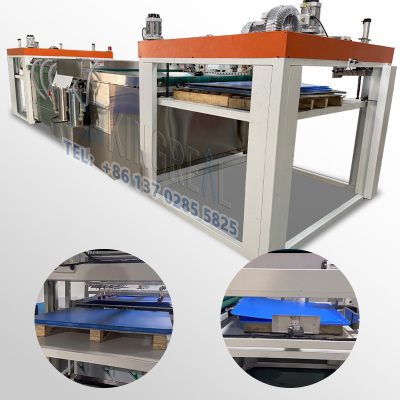

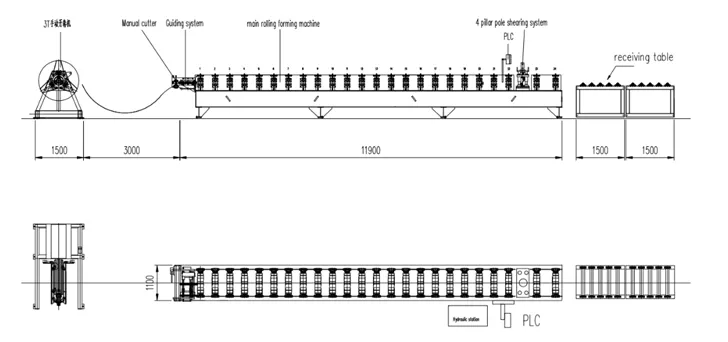

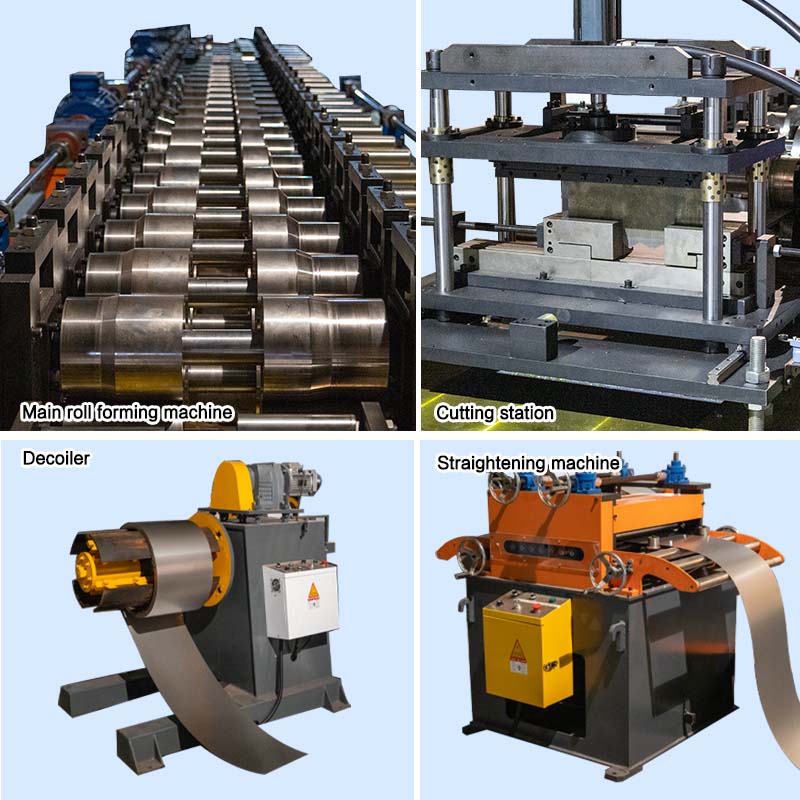

Working Process of Metal Wall Cladding Panel Machine

Decoiler → Leveling Machine → Roll Forming Machine → Cutting Station → Output Table

Parameter of Wall Siding Panel Machine

Machine Specifications | Weight | About 5000kgs |

| Color | According to customers’ requirement | |

Suitable Raw Material | Material | Cold rolled steel, galvanized steel, aluminum, copper, stainless steel and zinc... |

| Thickness | 0.4-0.7mm | |

| Coil width | 600-610mm | |

| Yield Strength | 235Mpa | |

Main Technical Parameters | Quantity of forming rollers stations | 20 |

| Diameter of forming rollers shafts | 75mm | |

| Roll Forming Speed | 20m/min | |

| Forming rollers material | No.45 steel, coated with chromed treatment | |

| Cutter material | CR12 mold steel, with quenched treatment | |

| Controlling system | PLC and Converter | |

| Electric Power requirement | Main motor power: 4kw | |

| Hydraulic unit motor power | 3kw | |

| Electric voltage | According to customers’ requirement |

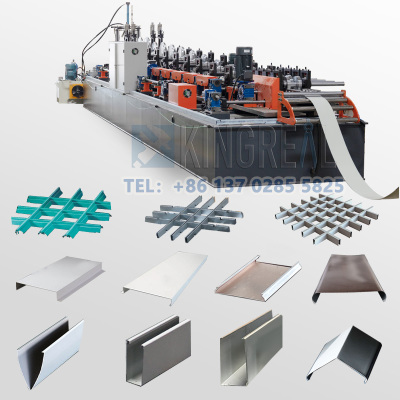

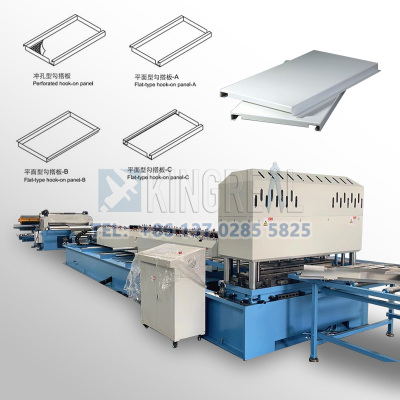

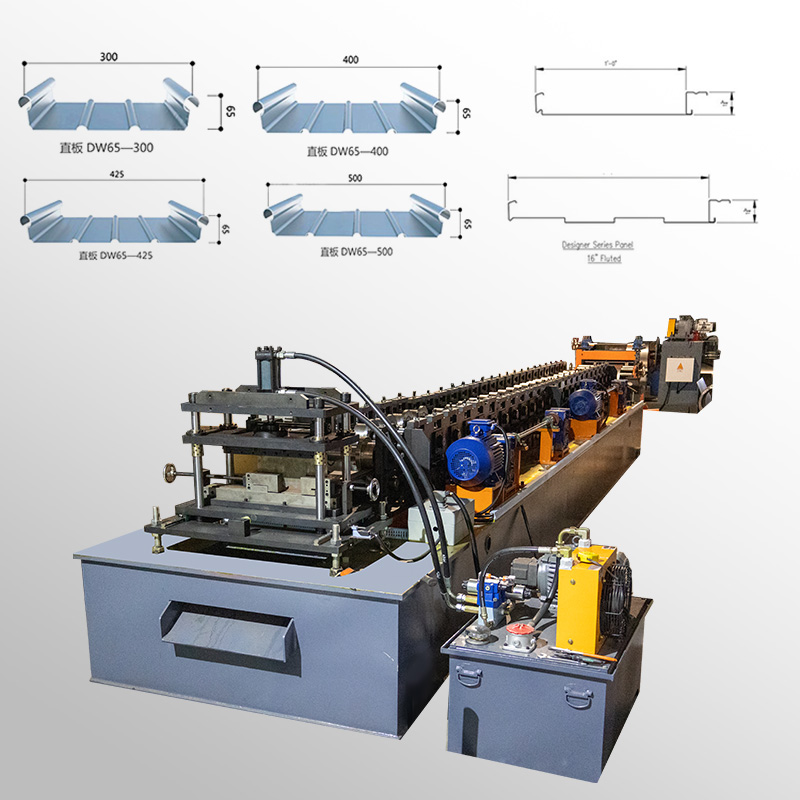

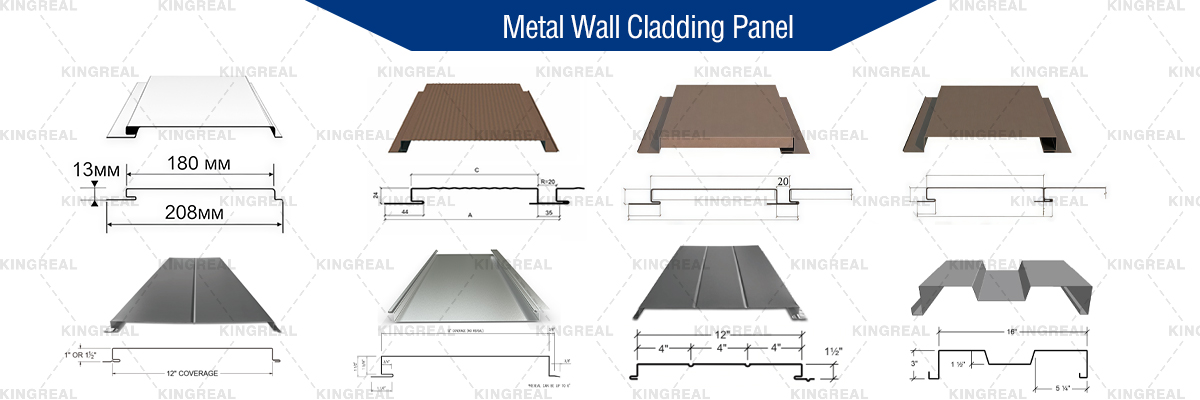

What Can KINGREAL CEILING MACHINERY Wall Siding Panel Machine Produce?

Advantages of Metal Wall Cladding Panel Machine

1) Efficient wall siding panel machines

KINGREAL CEILING MACHINERY metal wall cladding panel machines have the ability to produce continuously and run at high speeds, which significantly improves productivity. The entire production process is more economical by reducing labor costs and minimizing material waste.

In addition, this wall siding panel machine uses fully automatic control (CNC) systems to ensure the accuracy and consistency of the production process. The automatic feeding, cutting and stacking systems greatly reduce manual labor, improve production efficiency, ensure that the finished product size is accurate and the quality is stable, and the production speed can reach up to 20 m/min.

2) Versatile metal wall cladding panel machines

The design flexibility of this wall siding panel machine enables it to meet various construction needs. It can produce a variety of wall siding panels, included concealed fastener panels and exposed fastener panels. The metal wall cladding panel machine can adjust the thickness, width and length of the wall siding panels, and can also produce metal wall cladding panels with specific patterns, perforations or embossing.

In addition, the wall siding panel machine is highly compatible and can process a variety of metal materials such as steel, aluminum, zinc, copper and stainless steel, suitable for coated or pre-coated metals.

3) User-friendly metal wall cladding panel machine

Equipped with advanced control systems and low maintenance requirements, the wall siding panel machine’s operating convenience is greatly improved. Operators can easily set up and adjust the metal wall cladding panel machine to produce wall cladding panels of different shapes and sizes with minimal effort, thereby improving production flexibility and efficiency.

4) Wall siding panel machine with high safety performance

The metal wall cladding panel machine is designed with full consideration of the operator's safety and is equipped with safety guards, emergency stops and sensors to ensure maximum protection of staff safety during operation.

Why Does Russia Need Wall Siding Panel Machines?

1.Adaptability to Geographical Environment: Russia experiences extreme climate variations, including cold winters and warm summers. Metal wall panels produced by KINGREAL CEILING MACHINERY wall siding panel machines offer excellent weather resistance and thermal insulation, effectively resisting both extreme cold and heat, making them suitable for various construction projects. Furthermore, in regions with consistently high humidity, such as Siberia and the Far East, the machine-produced metal wall panels possess excellent waterproofing properties, effectively preventing moisture penetration and protecting the building structure.

2. Economic Benefits: By purchasing a wall siding panel machine, Russian customers can produce wall panels locally, reducing reliance on imported materials and lowering logistics costs. Local production also contributes to rapid market responsiveness.

3. Technological and Process Advantages: Wall siding panel machines offer rapid production, typically reaching speeds of up to 20m/min, significantly improving construction efficiency, especially suitable for large-scale construction projects. Moreover, KINGREAL CEILING MACHINERY wall siding panel machines can be customized to meet customer needs, supporting the production of different specifications and types of wall panels to suit various architectural styles.

FAQ about Metal Wall Cladding Panel Machine

1/ How to ensure that the wall siding panel machine produces high-precision finished products?

KINGREAL CEILING MACHINERY has equipped the metal wall cladding panel machine with high-precision components, including a hydraulic system with fast cooling, low failure rate and extended service life of the hydraulic pump station, ensuring that the equipment can run 24 hours a day without stopping.

In addition, the cutting station has adjustable cutting length and quantity, as well as speed control, to further improve production accuracy.

2/ What services can KINGREAL CEILING MACHINERY provide?

KINGREAL CEILING MACHINERY provides comprehensive services, with dedicated personnel in charge of each stage from pre-sales, sales to after-sales. This includes accompanying customers to visit the factory, explaining functions, customized wall siding panel machine manufacturing solution design, machine inspection, packaging and delivery, machine installation and operation training.

The entire process is fully responsible by KINGREAL CEILING MACHINERY staff to ensure that customer needs are fully met.

3/ How to ensure that the metal wall cladding panel machine can match the customer's production?

Every wall siding panel machine sold by KINGREAL CEILING MACHINERY is customized according to the actual production needs of the customer. KINGREAL CEILING MACHINERY engineers have a deep understanding of customer needs, including output, production scale, material thickness, and finished product type.

KINGREAL CEILING MACHINERY will adjust the machine performance parameters according to the customer's industry and region to ensure that the metal wall cladding panel machine sold can fully match the customer's production requirements.

Success Project -- Wall Siding Panel Machine

One of KINGREAL CEILING MACHINERY Greek customers is a wall siding panel supplier that works with multiple local construction projects and has diverse needs. For this reason, KINGREAL CEILING MACHINERY engineers equipped this metal wall cladding panel machine with an emergency stop, overload protection and protective shields to ensure the safety of the operator.

At the same time, a good ventilation and cooling system is designed to prevent the wall siding panel machine from overheating in high temperature environments.

And the highly adaptable metal wall cladding panel machine is customized according to the production scale and specifications of Greek customers to meet their diverse market needs.

This wall siding panel machine has been sent to the Greek customer's factory this month, and we look forward to KINGREAL CEILING MACHINERY engineers going to Greece to install and trial the metal wall cladding panel machine.

Packaging & Shipping

At the end of 2025, an advanced wall siding panel machine was meticulously packaged and boxed by the KINGREAL CEILING MACHINERY team, and then loaded onto a large truck using cranes and forklifts. The truck was prepared to take it to the port and then ship it to the customer's factory in Kazakhstan. The KINGREAL CEILING MACHINERY team handled the packaging process themselves, and a dedicated person sent photos and videos of the shipping process to the customer to keep them informed of the wall siding panel machine's latest progress. After the wall siding panel machine was shipped, KINGREAL CEILING MACHINERY logistics specialists also monitored its logistics information closely. This ensured that upon the wall siding panel machine's arrival at the customer's factory in Kazakhstan, KINGREAL CEILING MACHINERY engineers would be on-site to install the wall siding panel machine and provide operation training.

Application of Wall Siding Panel Machine

Metal wall cladding panels are commonly used in commercial and industrial buildings, but can also be used in residential buildings. They are versatile and suitable for new construction and renovation projects. Currently, the construction industry is developed in the United States, India, the Middle East and North Africa, so the demand for metal wall cladding panels is also very strong.

Wall siding panels produced by KINGREAL CEILING MACHINERY metal wall cladding panel machines are generally low-maintenance and only require regular cleaning and inspection to ensure their integrity.

When considering wall panels for a construction project, you need to choose products that meet the specific requirements of the project, including aesthetics, weather resistance, insulation, and structure.

In addition, local building codes and regulations should be followed during installation.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)