Hook On Ceiling Tile Roll Forming Machine

KINGREAL CEILING MACHINERY Hook-On Ceiling Tile Production Line is designed to produce different size hook-on ceilings, which can maintain panel performance and is the ideal solution for a variety of commercial and industrial applications.

- KINGREAL CEILING MACHINERY

- CHINA

Details

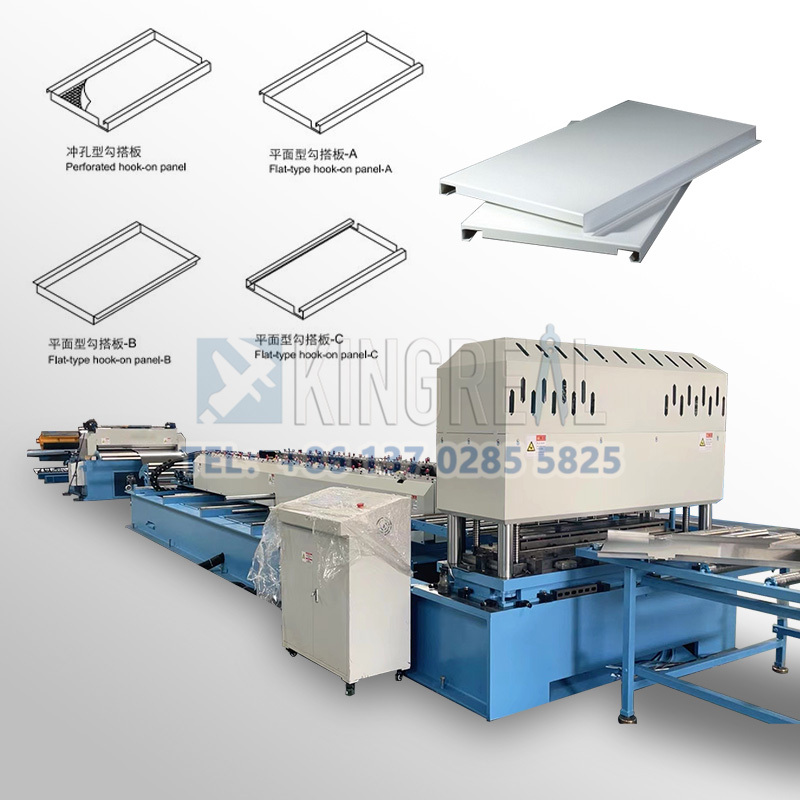

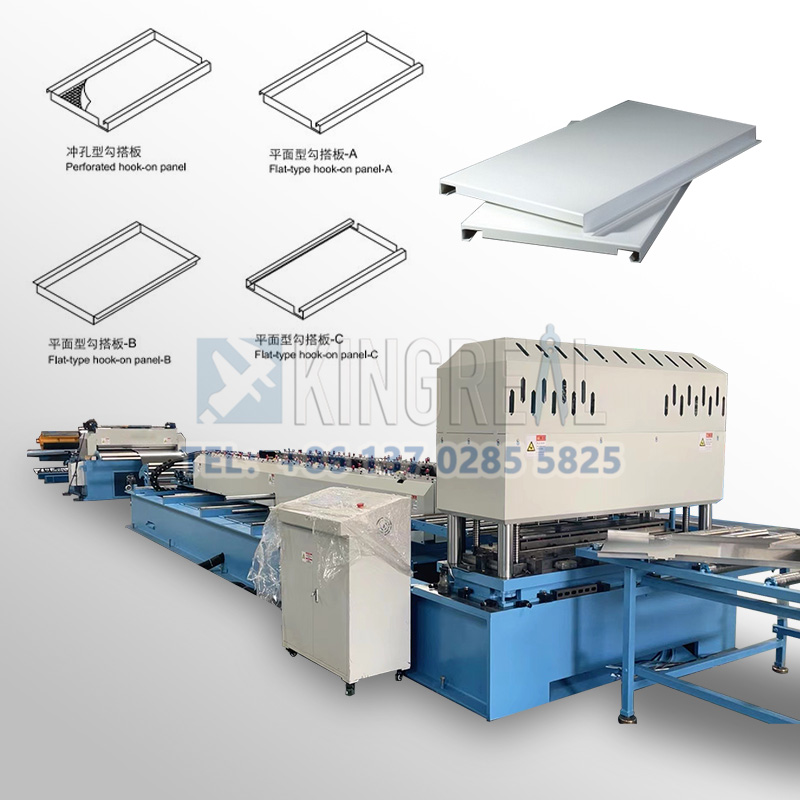

Description About Hook On Ceiling Forming Machine

KINGREAL CEILING MACHINERY Hook-On Ceiling Tile Production Line is designed to produce different size hook-on ceiling tiles, which can maintain panel performance and is the ideal solution for a variety of commercial and industrial applications.

A solid, easily accessible ceiling system is provided by hook-on metal ceilings. Black iron is not necessary for heavy-duty extruded aluminum suspension, which is wire-hung. The system complies with CISCA and ASTM requirements.

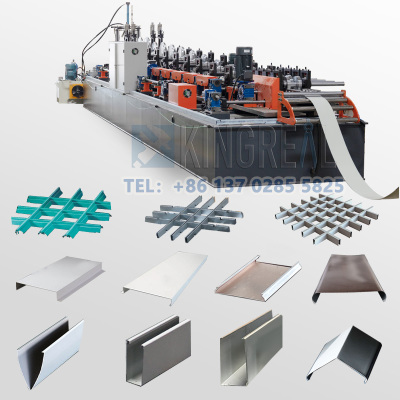

KINGREAL CEILING MACHINERY hook on ceiling tile machine usually uses different metal materials with a thickness of 1.0~3.0mm, including aluminum, stainless steel, steel, etc. as metal raw materials to produce rectangular, square, and perforated hook ceiling tiles of different sizes such as 600x600mm and 600x1200mm.

The produced hook ceiling tiles have the characteristics of light weight, fire resistance, weather resistance, no corrosion, and easy disassembly and assembly.

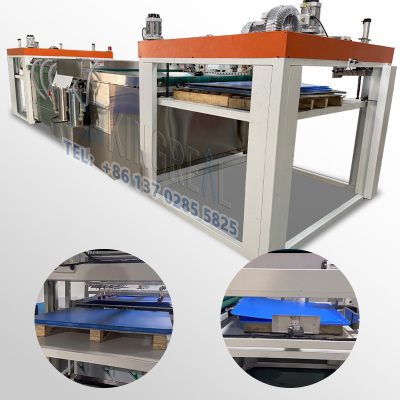

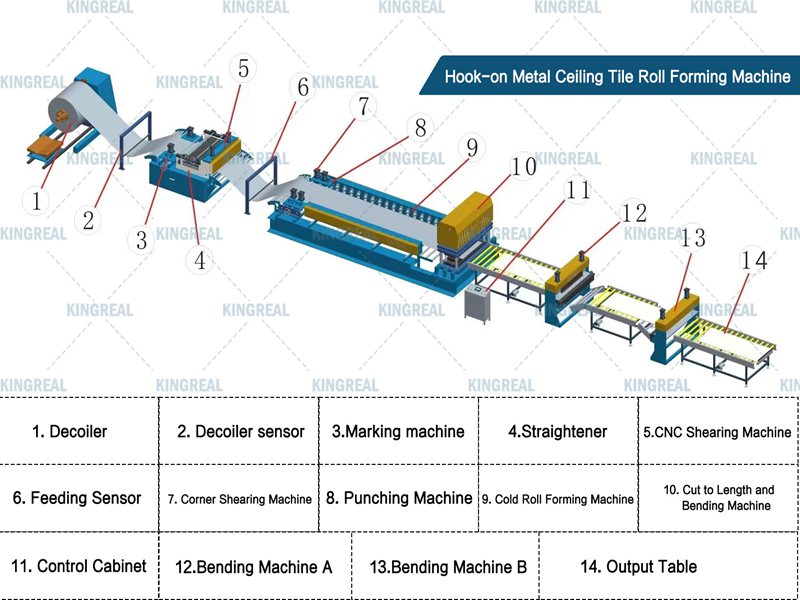

Working Process Of Hook On Ceiling Production Line

Strip Pieces Feeding -- Main Roll Forming Machine(Width Adjustable) -- Discharge (Hook) -- Discharge (On) -- Conveying -- Bending Part -- Output Table

Specifications Of Hook on Ceiling Tiles

| Panel Material | Aluminum, Stainless Steel, Steel and so on |

Ceiling Width | 3‘-0" or more Panels can be up to 8 feet long. |

Surface | Flat and either perforated or unperforated Rectangle and square are typical shapes. |

Hook On Ceiling Tile Size | 300*300mm, 300*600mm, 300*1200mm 600*600mm, 600*1200mm, 800*800mm, 1000*1000mm Width from 300-1000 Length from 200-2000mm Thickness: 1.0-3.0mm |

Advantages Of Hook On Ceiling Production Line

1. Structure of a Sturdy Roll Forming Machine

The hook on ceiling tile machine's fundamental panel is built of excellent steel and has a superb 30mm thickness. It was additionally divided by various servo motors. Please take note that this panel can guarantee machine durability throughout prolonged use.

2. Auto-Adjustable Width for Hook on Ceiling Tile Machine

Yaskawa well-built servo motors were used to power this assembly line and place the roller stands precisely. The hook on ceiling tile machine is also computer controlled, so adjustments only require input to the system; the remainder will be completed by the machine itself. With this design, the hook on ceiling tile machine can easily produce hooking boards of different sizes.

3. High-precision Hook on Ceiling Tile Machine

This hook on ceiling tile machine is capable of producing high-quality hook on ceiling tiles with a profile accuracy of ±0.2mm. The roll forming machine is equipped with 20 sets of rollers, which greatly improves the accuracy and stability of the production process.

The advantage of multiple sets of rollers is that they can evenly distribute the pressure, ensuring that the material is better supported and guided during the forming process, thereby reducing the possibility of deformation and errors.

In addition, the coordinated work of multiple roller sets can effectively reduce the friction of the material, improve the forming efficiency, and ultimately ensure that the produced profiles meet strict specifications.

4. Easy-to-operate Hook on Ceiling Tile Machine

This hook on ceiling tile machine is equipped with an advanced PLC control panel, which makes it particularly simple for users to enter production parameters.

Simply enter the required production data on the control panel, and the hook on ceiling tile machine can run automatically, greatly improving production efficiency and convenience of operation.

This design not only reduces the need for human intervention, but also reduces production problems caused by human errors.

Application of Hook on Ceiling Tile Machine

The hook on ceiling tiles produced by the hook on ceiling tile machine are suitable for areas with heavy traffic, such as subways, airports, stations, passages, theaters, modern large shopping malls, exhibition centers and other large open public places.

Hook On Ceiling Tile Product

| Width | Length | Height | Thickness | |

| 300x1200 | 300 | 1200 | 30 | 0.7-2.0 |

| 600x600 | 600 | 600 | 30 | 0.7-2.0 |

| 600x1200 | 600 | 1200 | 30 | 0.8-2.5 |

| 1200x1200 | 1200 | 1200 | 30 | 2.0-2.5 |

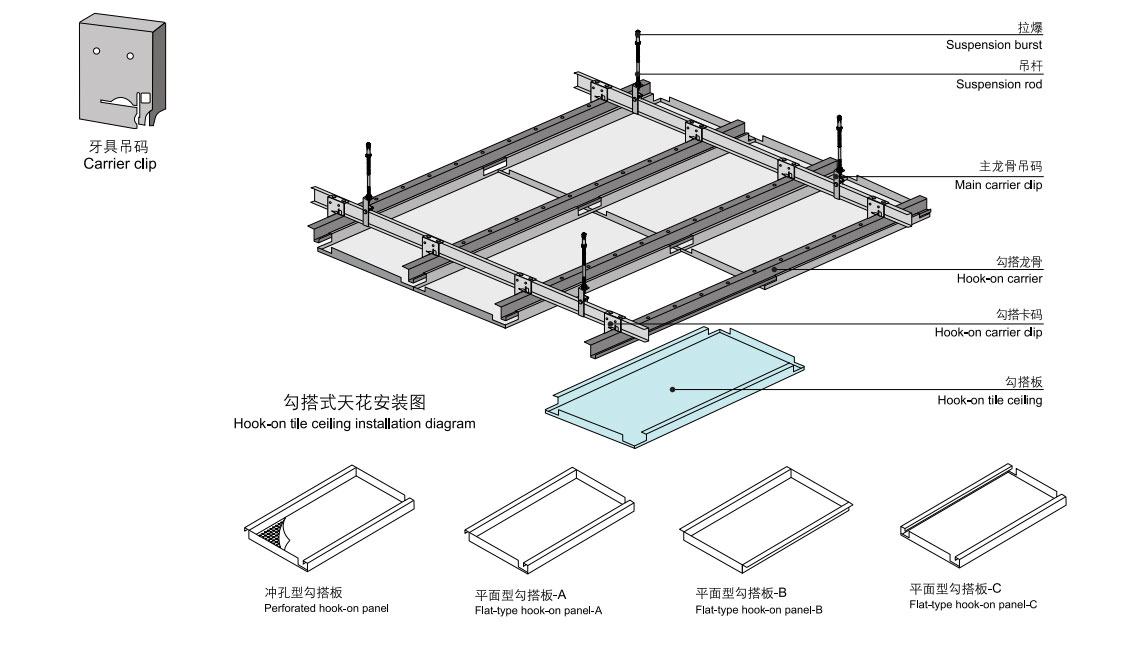

Installation Drawing About Hook on Ceiling Tile

FAQ About Hook on Ceiling Tile Machine

Q1:How long will you send the proposal and offer?

A1:We will need about 3~7 days to design the proposal upon collecting all details of the above mentioned info necessary.

Q2:How long do you need to install and commission the hook on ceiling tile machine?

A2: Usually one week for installing and teaching workers about how to operate.

Q3:How many people will come to install and commission the hook on ceiling tile machine?

A3: Usually 1 engineer is enough to do all the things. All his expenses during this travel will be paid by the buyer accordingly.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)