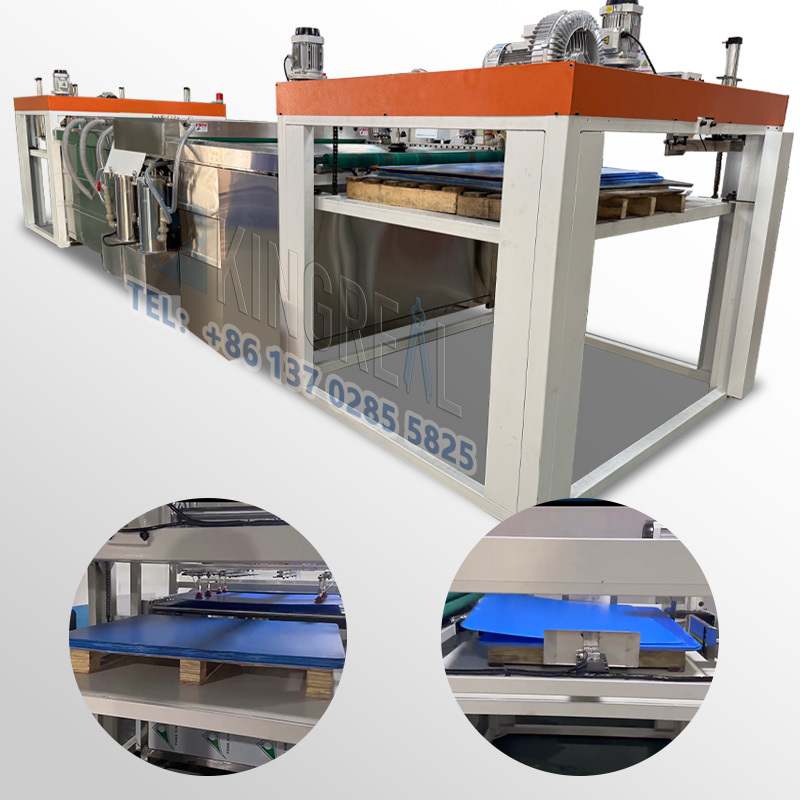

Pallet Layer Pads Washing And Drying Machine

KINGREAL CEILING MACHINERY is one of the professional manufacturers of sheet processing and forming equipment in China, which can provide different production equipment according to customers' needs. This layer pad washer is suitable for different materials to realize high quality cleaning effects. Welcome to contact us for the latest design program.

- KINGREAL CEILING MACHINERY

- China

Details

Video Display About Layer Pad Washing Machine

Description of P

allet Layer Pads Washing and Drying Machine

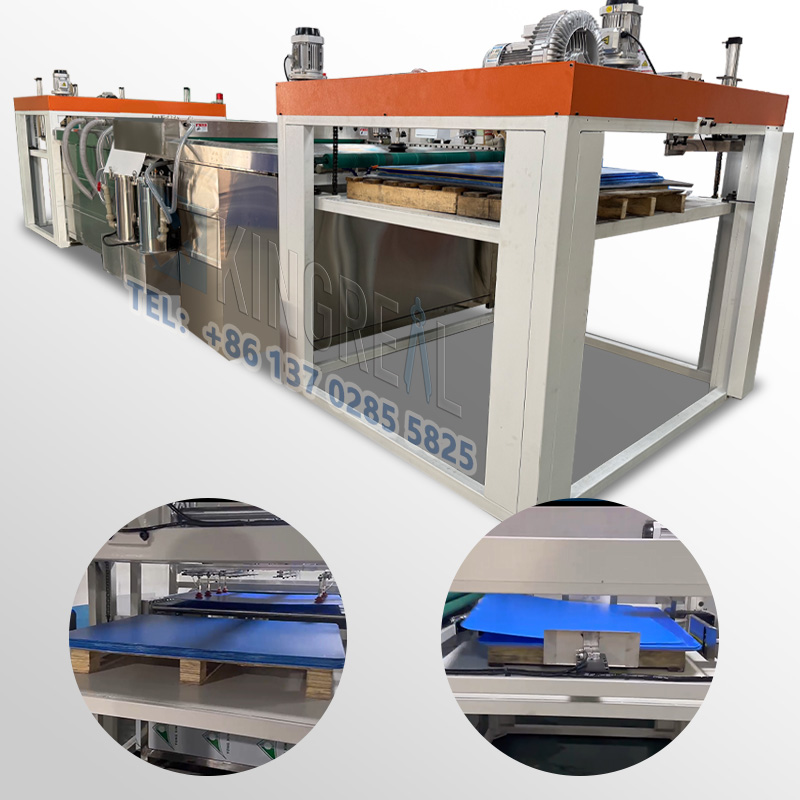

KINGREAL CEILING MACHINERY Full Auto Pallet Layer Pads Washing and Drying Machine is mainly used for cleaning and drying different plastic layer pads. It adopts advanced automation technology and washing principles, allowing for quick and thorough cleaning of mat boards to ensure their hygiene and safety. It is widely used in the fields of catering, food processing, medical and health care, and has become an indispensable equipment in the modern production environment. |  |

Working Process of L

ayer Pad Washer

Automatic Loading ( adopt the manipulator ) -- Washing -- Drying -- Automatic Stacking

Main Components of P

allet Washer Machine

1. Cleaning Section of layer pad washer

The cleaning system includes a spraying device, a brushing device and a water pump. The spraying device removes dirt and bacteria by spraying a washing solution that evenly covers the surface of the mat board. The brushing device further cleans the mat board by rotating the brushes or brush disks to scrub the mat board.

The pallet washer machine is equipped with at least four water tanks, which can thoroughly clean the pallet layer pad multiple times. This multi-stage cleaning design ensures that each layer pad can reach a high standard of cleanliness.

In addition, the pallet washer machine also has a heating function, which can use hot water up to 100°C for cleaning, further improving the decontamination effect.

In order to enhance the cleaning ability, users can also choose to add special cleaning agents, which can not only effectively remove oil and dust, but also deeply clean stubborn dirt, thereby ensuring the clean state of the layer pad and meeting high production standards.

2. Control System

The fully automatic plastic layer pad washer is equipped with an advanced control system, which can realize automatic operation and precise control. Users can select different washing programs, and adjust the washing time and temperature and other parameters through the touch screen or buttons to meet different washing needs.

3. Drying Section of pallet washer machine

The drying section is one of the important parts of the machine. It can efficiently dry the washed mat boards quickly and thoroughly through advanced drying technology. This part of the pallet cleaning machine has a multi-layer drying system, which can handle multiple mat boards at the same time and improve production efficiency.

KINGREAL CEILING MACHINERY pallet layer pads washing and drying machine design incorporates advanced double-sided drying technology, which can efficiently dry the layer pad.

Through double-sided heating, it is ensured that the pallet layer pad is quickly dehydrated after cleaning, avoiding subsequent processing problems caused by residual moisture. This drying method not only improves production efficiency, but also prevents sheet deformation, thus providing a more ideal foundation for subsequent processing.

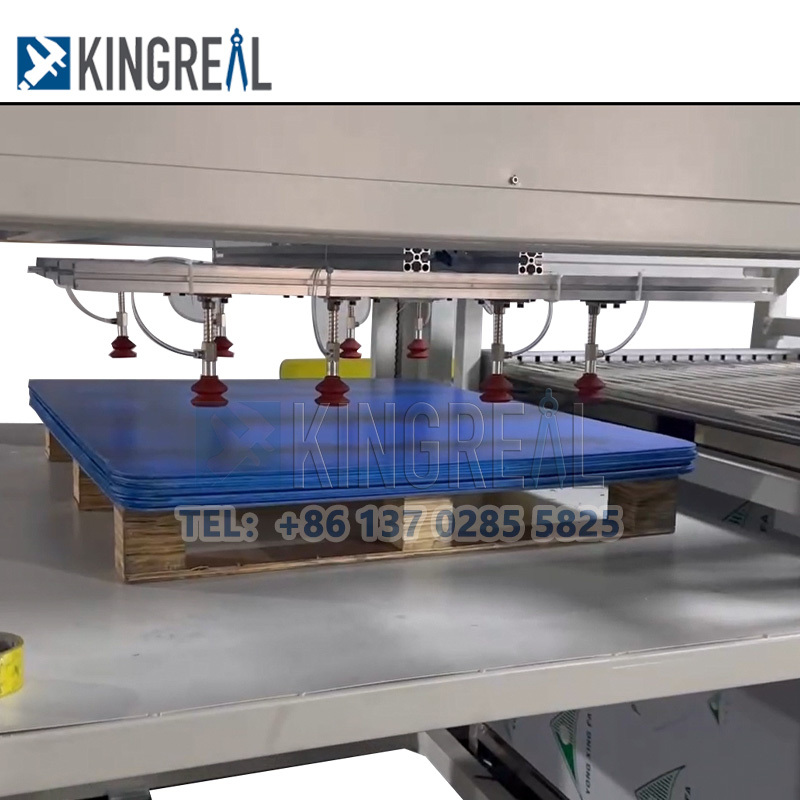

4. Stacking section of pallet washer machine

In order to further improve production efficiency, the automatic stacking machine is an optional equipment for the plate washer machine. It can automatically stack the pallet layer pads neatly after the pallet layer pads washing and drying machine completes cleaning and drying.

This process not only saves labor costs, but also ensures the neatness of the stacking, which is convenient for subsequent processing, packaging or transportation. Through this automated stacking method, enterprises can greatly improve work efficiency, optimize logistics management, and ensure the smooth progress of the production process.

Specification of L

ayer Pad Washer

| Materials Thickness | 4.0 - 4.5mm |

| Max.cleaning width | 800mm |

| Motor | 2.2KW |

| Speed | standard 7m/min |

| Power | 72KW |

Advanced Technology -- Adopting Manipulator for Loading

KINGREAL CEILING MACHINERY adopts a manipulator in the loading machine to achieve full auto-loading. Adopting a manipulator has the following advantages: 1.Upgrade the degree of automation: The manipulator is intelligent, it will not move if the material is overweight. 2.Improve production efficiency: The manipulator can work continuously without fatigue, thus significantly improving production efficiency. 3.High precision: The manipulator can accurately execute the preset program to ensure the accuracy of loading production step |  |

Another Option --

Metal Sheet Cleaning

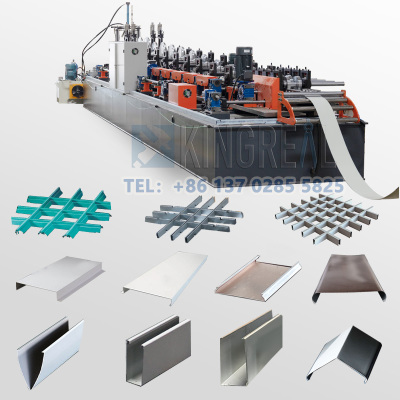

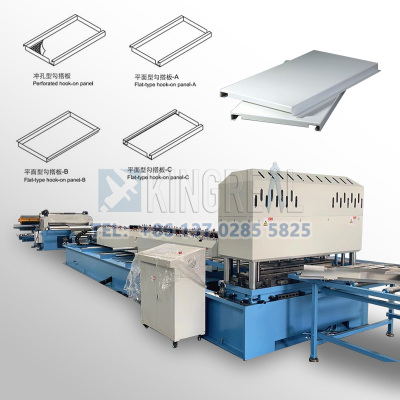

Machine

KINGREAL CEILING MACHINERY Metal Sheet Cleaning Machine is a specialized equipment for cleaning metal plates. It utilizes high-pressure water flow and appropriate cleaning agents to completely remove dirt, grease, dust and other substances from the surface of the metal plate in order to achieve a clean and smooth result. KINGREAL CEILING MACHINERY metal sheet cleaning machine can clean metal objects of various materials, including galvanized plates, stainless steel plates, mirror stainless steel plates, aluminum plates, metal ceiling tiles, etc.

Among them, KINGREAL CEILING MACHINERY metal sheet cleaning machine can wash metal sheets with a width of 500-1600mm and a thickness of 0-7mm, with a cleaning speed of up to 7m/min. The number of water tanks and drying ovens equipped for the metal sheet cleaning machine will be determined by KINGREAL CEILING MACHINERY engineers based on the actual cleaning conditions of the customer.

The parameters of the metal sheet cleaning machine mentioned above are for reference only. If you have higher requirements, please consult KINGREAL CEILING MACHINERY. KINGREAL CEILING MACHINERY will design a customized metal sheet cleaning machine for you. |  |

KINGREAL CEILING MACHINERY Successful Project

This Indian customer has extremely high requirements for the cleanliness of the pallet layer pads surface. For this reason, KINGREAL CEILING MACHINERY has developed an efficient layer pad washing machine specifically for this demand. With its powerful cleaning ability, this layer pad washing machine can completely remove dirt, oil stains and other impurities on the surface of the pallet layer pads, ensuring that customers can obtain the best surface quality in subsequent processing and application.

KINGREAL CEILING MACHINERY's pallet layer pads washing and drying machine uses advanced cleaning technology and an efficient cleaning system, which can flexibly adjust the cleaning parameters according to different types of pallet layer pads and the degree of contamination. This customized cleaning solution not only improves the cleaning effect, but also effectively saves cleaning time and maximizes production efficiency.

In addition, the design of the pallet layer pads washing and drying machine takes into account the ease and safety of operation, so users can easily get started and reduce training costs. The durability and stability of the equipment also provide customers with a long-term and reliable use experience, ensuring that it can still maintain efficient operation in a high-intensity production environment.

After-Sales Services

Services are always highly considered by KINGREAL CEILING MACHINERY, in addition to establishing a complete remote service system, localized after-sales service is also what KINGREAL CEILING MACHINERY has been insisting on doing. The global localization service point is under construction.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)