Wall Cladding Panel Production Line

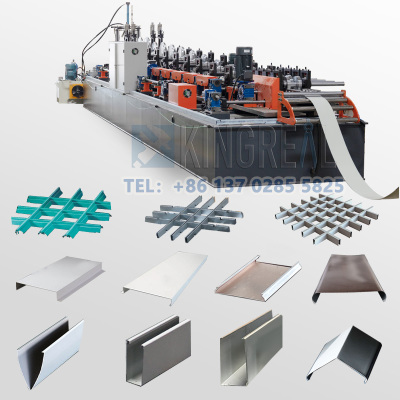

KINGREAL CEILING MACHINERY can provide the Wall Cladding Panel Production Line, which can produce aluminum or steel wall cladding panels up to 4FT width.

- KINGREAL CEILING MACHINERY

Details

Video About Wall Panel Roll Forming Machine

Description Of Wall Panel Roll Forming Machine

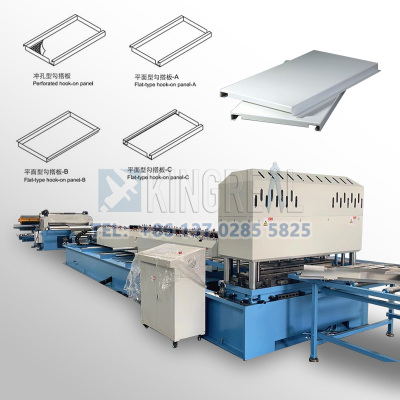

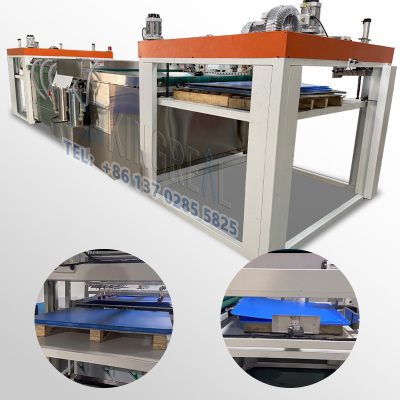

"KINGREAL CEILING MACHINERY can provide the Wall Cladding Panel Roll Forming Machine, which can produce aluminum or steel wall cladding panels up to 4FT width.The machine adopts raw materials uncoiler, notching, continuously cold roll forming, automatic cutting and folding and ready product output production process." KINGREAL CEILING MACHINERY fully automated metal wall panel making machine can process metal raw materials of different materials and produce wall panels of different sizes and types, such as corrugated sheets, trapezoidal panels, and interlocking designs, etc. And this wall cladding panel machine is compatible with a wide range of high-quality metal materials, including galvanized steel, aluminum, pre-painted steel, stainless steel, and other corrosion- and wear-resistant materials to meet various application needs.

The wall cladding panel machines are widely used in projects such as residential buildings, commercial complexes, industrial facilities, agricultural buildings, public infrastructure, renovation and transformation. Wall panels are popular among customers in the building materials industry because of their easy installation and economical features. The installation process is simple and fast, which can effectively save manpower and time costs. At the same time, the economy of wall panels makes them more competitive in terms of material and production costs, helping customers achieve higher profits in the market. |  |

Feature Of Wall Cladding Panel Machine

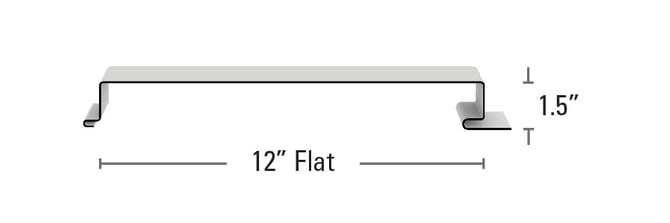

1. Pre-cutting system, which can be set to cut sheets according to any length of the customer. 2. The product width can be flexibly adjusted. One machine has a variety of width options (300-1200mm) to meet the needs of the market and customers with multiple specifications. 3. Adopt PLC control system to precisely control the width and size changes of products. 4. Profile Customization: Wall cladding panel machines can be customized to produce different profiles and patterns based on the design requirements of concealed fastener wall panel. The operators can adjust settings to achieve the desired wall panel shape and size. |  |

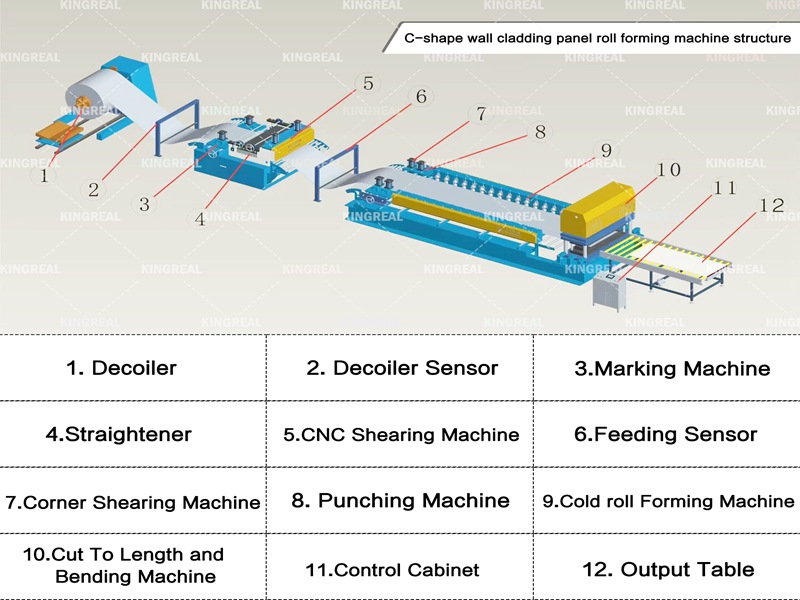

Working Process of Wall Cladding Panels Making Machine

Decoiler -- Decoiler Sensor -- Marking Machine -- Straightener -- CNC Shearing Machine -- Feeding Sensor --Corner Shearing Machine -- Punching Machine -- Cold Roll Forming Machine -- Cut To Length and Bending Machine -- Control Cabinet --Output Table

Advantage of Wall Cladding Panel Roll Forming Machine

1. Fully automatic wall cladding panel machine

Fully automated wall cladding panel roll forming machine, reduce production costs. The equipment is fully automatic production equipment, from raw material uncoiling to final cutting and discharging are fully automatic, which can reduce the number of labor, reduce production costs and improve production efficiency.

2. High-quality wall cladding panel machine

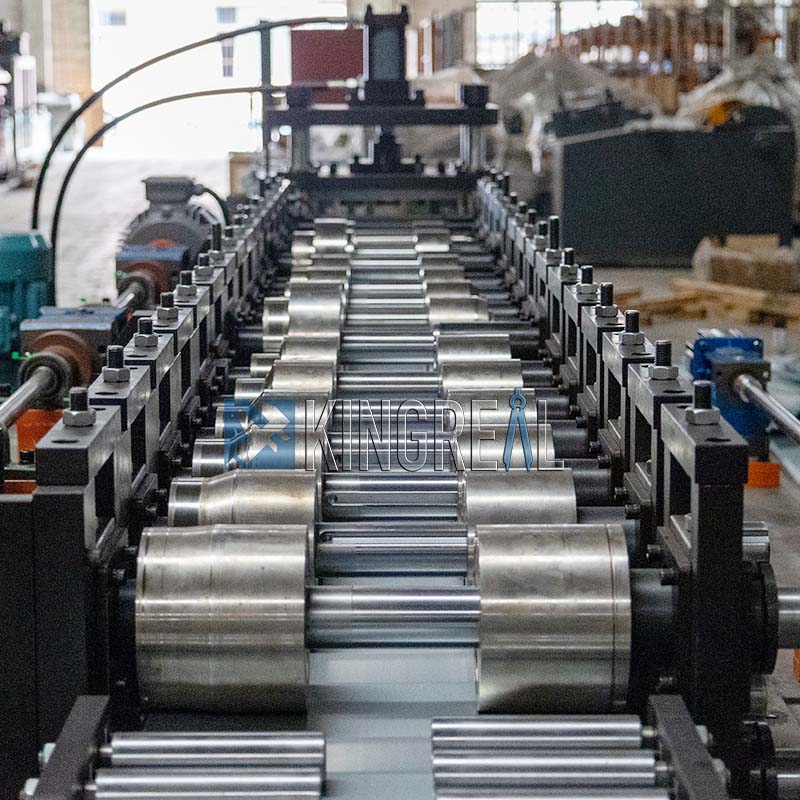

The rollers of the equipment are all chrome-plated, which ensures the accuracy and quality of the product during the rolling process, and prolongs the service life of the machine.

3. Smooth operation for wall cladding panel machine

KINGREAL CEILING MACHINERY follows a rigorous process in the manufacturing process of the metal wall cladding panel making machine to ensure that every link meets high standards. In the selection of raw materials, KINGREAL CEILING MACHINERY strictly controls the quality of each material. Because of this, the wall panel roll forming machine produced by KINGREAL CEILING MACHINERY has excellent operating stability. Whether in a high-load production environment or in long-term continuous operation, KINGREAL CEILING MACHINERY wall cladding panel machine can maintain stable operation, thereby reducing the failure rate and improving production efficiency.

4. High precision for wall cladding panel machine

KINGREAL CEILING MACHINERY wall cladding panel production line is carefully composed of high-precision components such as decoiler, roll forming machine, and cutting station. Each component undergoes strict quality inspection and debugging to ensure its precision and reliability. This precise combination makes the wall panels produced by KINGREAL CEILING MACHINERY wall cladding panel roll forming machine have extremely high precision, smooth surface without scratches, and the consistency of the product has been significantly improved. This ensures a seamless installation and professional look for the wall panels.

Main Components Of Wall Cladding Panels Making Machine

| 1 | Decoiler |

| 2 | Decoiler Sensor |

| 3 | Marking machine |

| 4 | Straightener |

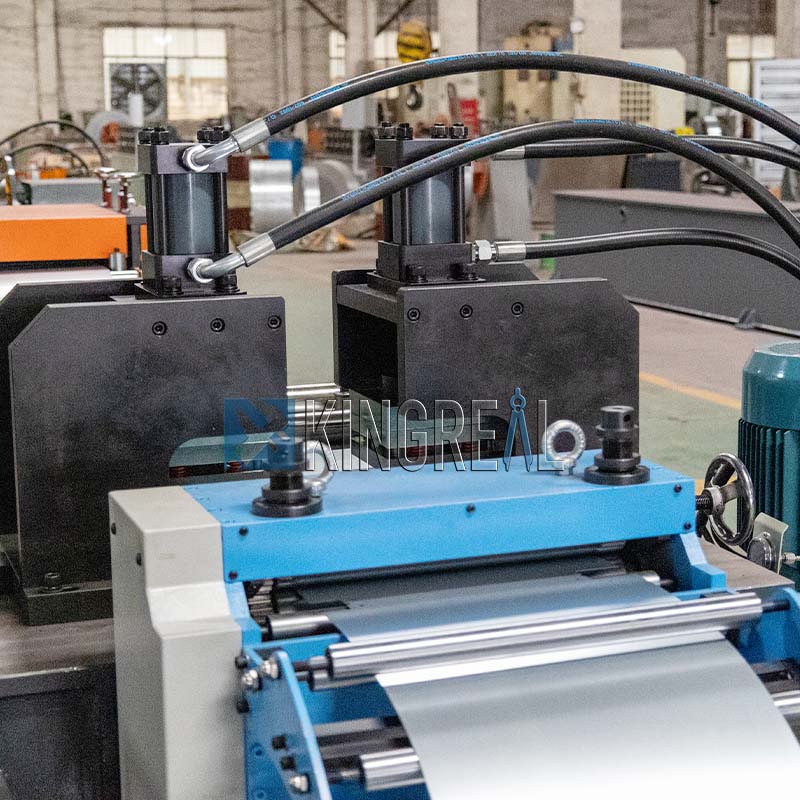

| 5 | CNC Shearing Machine |

| 6 | Feeding Sensor |

| 7 | Corner Shearing Machine |

| 8 | Punching machine |

| 9 | Cold Roll forming machine |

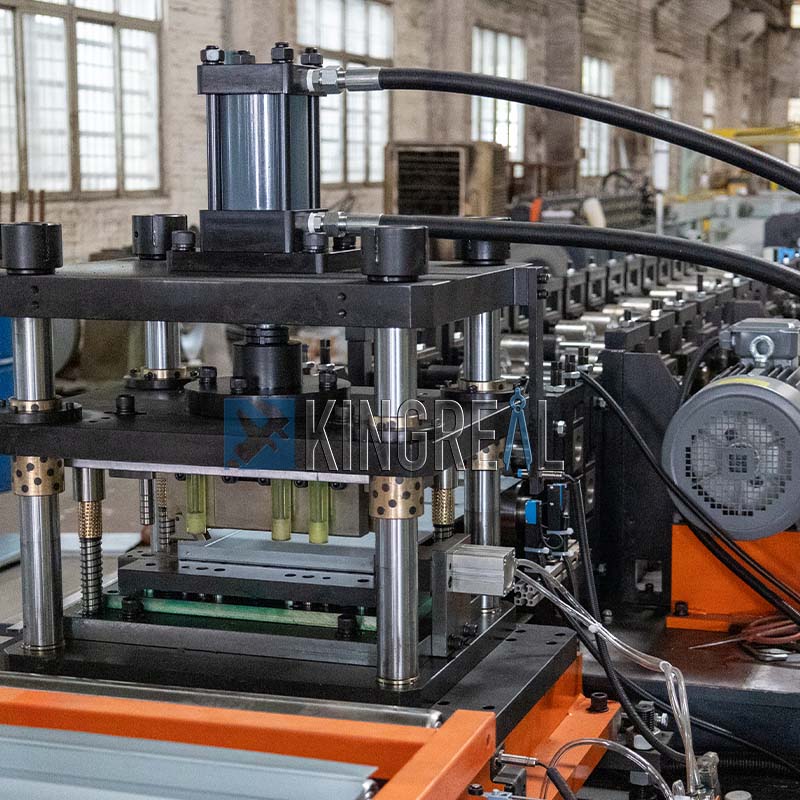

| 10 | Cut to length and bending machine |

| 11 | Control cabine |

| 12 | Output table |

Technical Parameters of Wall Cladding Panel Machine

Uncoiler | Hydraulic decoiler |

Inner diameter | 480-520mm |

Outer diameter | 1250mm |

Loading weight | 5TONS |

Forming speed | 0—20m/min |

Machine base | welded with 36 # H beam-steel |

Material of Shafts | 45# high quality steel |

Diameter of Shafts | 70mm |

Material of Roller high quality | 45#steel coated |

Motor Power | 5.5 KW |

Hydraulic Power | 3 KW |

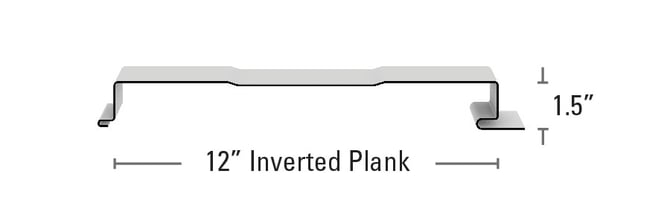

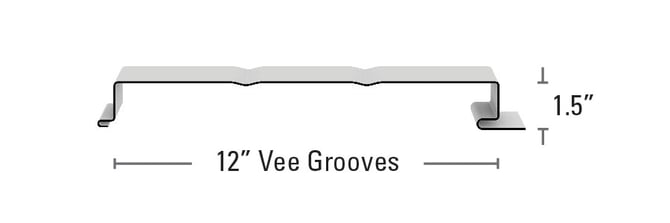

Drawing About Concealed Fastener Wall Panel

Application Of Cladding Wall Panels

The scope of this product application includes the decorative surface of various objects such as industrial and administrative buildings, shopping centers, stadiums, markets, office buildings, etc. Cladding wall panel have long service life and beautiful appearance. Therefore, more and more factory choose to purchase the Wall Panel Roll Forming Machine to produce this wall panel.

KINGREAL CEILING MACHINERY is committed to providing customers with a variety of wall cladding panel roll forming machines to meet the production needs of different types of wall panel. KINGREAL CEILING MACHINERY understands the market's diverse needs for wall panel products, so it has developed a variety of wall cladding panels making machines to ensure that customers can get the most suitable equipment for their products. KINGREAL CEILING MACHINERY has the corresponding wall panel making machines to produce the common flat panel, v-rib, pencil rib or clip relief types of wall panels on the market.

Why Choose Cladding Wall Panel Machine?

(1) High-quality cladding wall panel machine

KINGREAL CEILING MACHINERY manufacturing team comprises professionals with over ten years of experience. They are deeply familiar with the manufacturing processes and technical methods of each cladding wall panel machine component and maintain a rigorous and meticulous approach. KINGREAL CEILING MACHINERY cladding wall panel machines are manufactured using high-quality raw materials, and after completion, customers are invited to visit KINGREAL CEILING MACHINERY factory for a test run. The manufacturing process is considered complete only when the customer is satisfied with the cladding wall panel machine's performance and the precision of the finished product. If the customer has any concerns about the cladding wall panel machine, KINGREAL CEILING MACHINERY will perform a commissioning upon request. If the requirements are still not met, we will remanufacture the cladding wall panel machine. This ensures that KINGREAL CEILING MACHINERY provides high-quality cladding wall panel machines that fully meet the customer's actual production and project needs.

(2) Comprehensive after-sales service for cladding wall panel machine

After the cladding wall panel machine is shipped to the customer's factory, KINGREAL CEILING MACHINERY dispatches professional engineers to install it on-site and provide training on cladding wall panel machine operation. The engineers also provide daily maintenance instructions to ensure proper operation and extend the cladding wall panel machine's lifespan, maximizing customer benefits. If the cladding wall panel machine's components wear out after prolonged use, KINGREAL CEILING MACHINERY also provides spare parts. No matter how long ago the cladding wall panel machine was sold, please feel free to contact KINGREAL CEILING MACHINERY if you encounter any problems. KINGREAL CEILING MACHINERY staff will respond quickly and provide solutions.

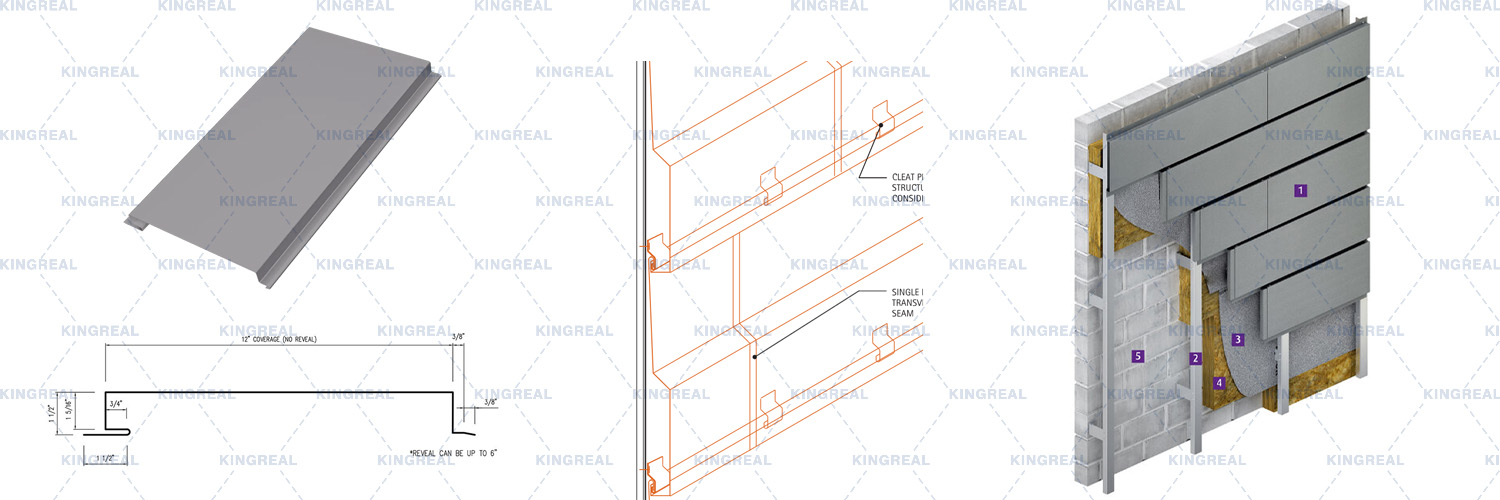

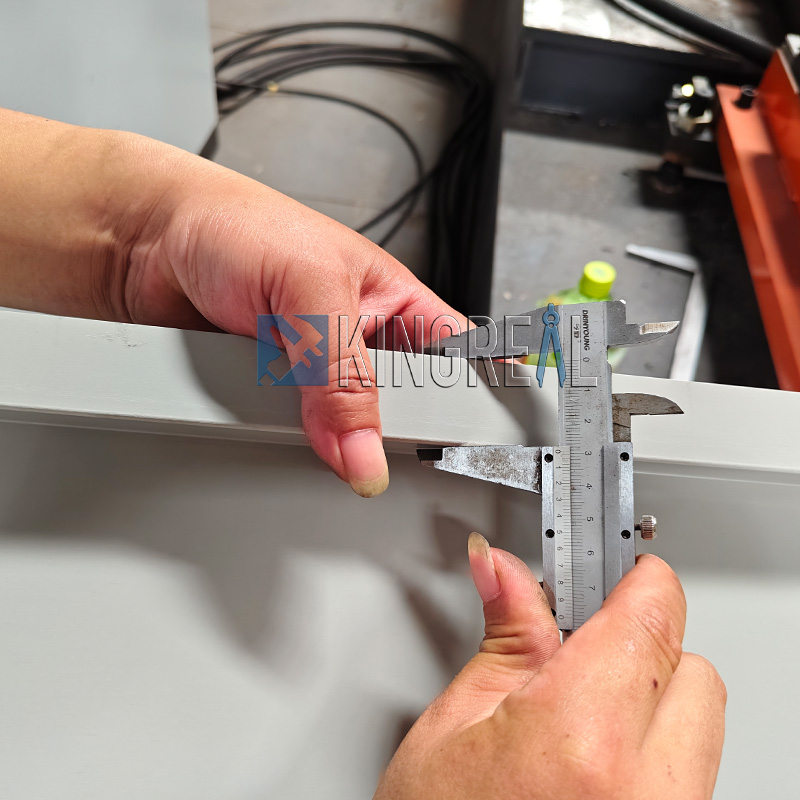

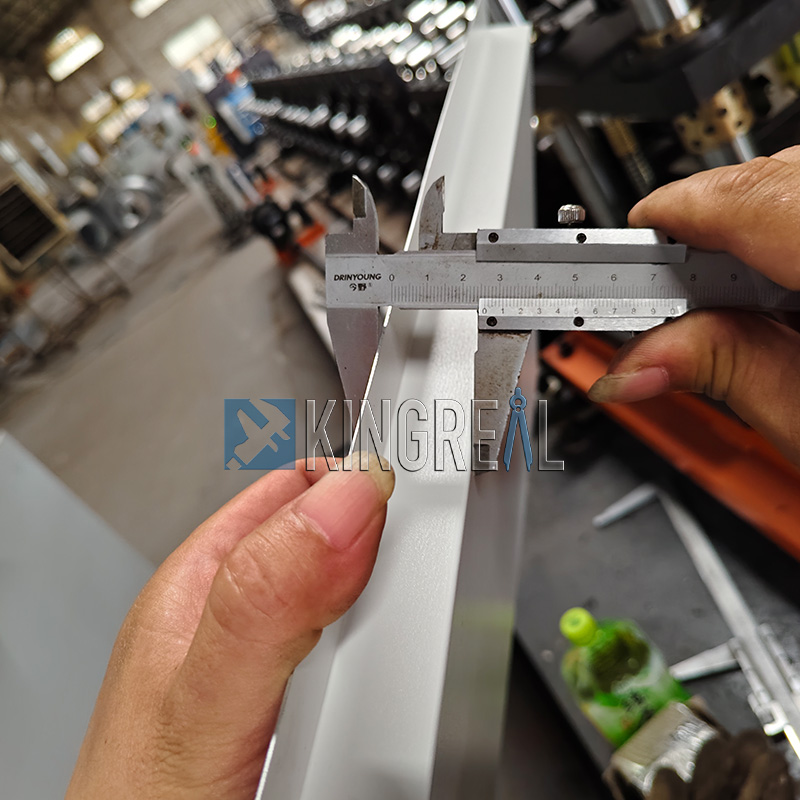

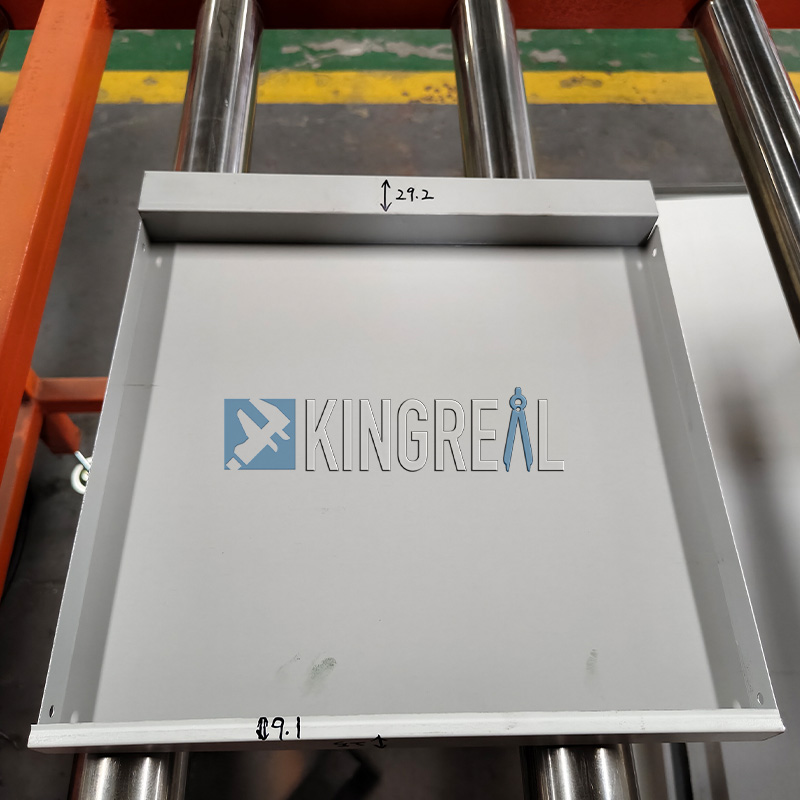

Quality Inspection

Before shipping, the KINGREAL CEILING MACHINERY team conducts a comprehensive inspection of each cladding wall panel machine, including its appearance, operational status, and the quality of the finished products. Typically, KINGREAL CEILING MACHINERY invites customers to the factory for on-site inspection. If the customer cannot attend, the KINGREAL CEILING MACHINERY team will conduct a detailed inspection on their behalf. Test results will be sent to the customer via video, images, and written documentation to ensure transparency and clarity. Upon inspection, KINGREAL CEILING MACHINERY cladding wall panel machines are found to produce high-quality wall panels with small tolerances, smooth, burr-free surfaces, and high consistency. Shipment will only proceed after customer approval.

Customer Visit

KINGREAL CEILING MACHINERY warmly welcomes customers from around the world to visit its factory and experience cladding wall panel machines. At the factory, customers can operate the cladding wall panel machines themselves and inspect the finished products. KINGREAL CEILING MACHINERY is confident in providing customers with an advanced and high-quality cladding wall panel machine. During the visit, professional KINGREAL CEILING MACHINERY staff will accompany the customer throughout, explaining the cladding wall panel machine's functions and production processes in detail, helping customers gain a comprehensive understanding of KINGREAL CEILING MACHINERY cladding wall panel machines. A customer's in-person factory visit is the best way to quickly understand and evaluate whether KINGREAL CEILING MACHINERY cladding wall panel machines meet their actual project needs. KINGREAL CEILING MACHINERY is committed to providing comprehensive services to its customers, ensuring that every customer experiences KINGREAL CEILING MACHINERY professionalism and efficiency.

Packaging & Shipping

In July of this year, a fully automated cladding wall panel machine was shipped from China to a customer's factory in Greece. KINGREAL CEILING MACHINERY staff meticulously packaged the cladding wall panel machine's components, including the decoiler, leveling machine, roll forming machine, cutting station, and output table, and safely transported them to the truck using a forklift and crane. After confirming that all components were fully loaded, the truck departed for the port to await shipment. Throughout this process, KINGREAL CEILING MACHINERY staff provided timely updates to the Greek customer on the cladding wall panel machine's packaging and shipping progress through videos and photos, ensuring they were kept informed. KINGREAL CEILING MACHINERY staff also closely monitored the logistics process for timely feedback.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)