How does baffle ceiling machine work?

2025-07-24 17:00

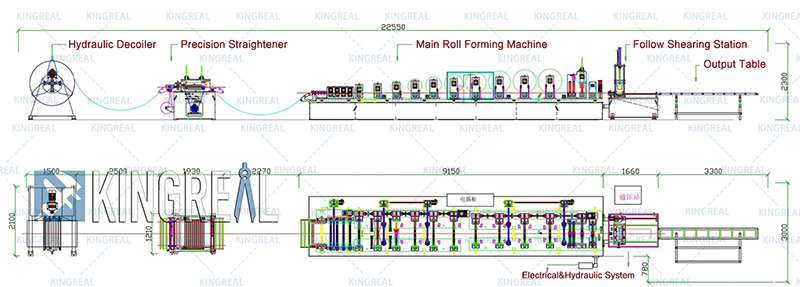

"Baffle ceiling machine is also called the u baffle machine. The baffle ceiling making machine is simple and reliable to operate, with a high degree of automation and high forming and shearing accuracy. The baffle ceiling machine is mainly composed of precision components such as decoiler, precision leveling machine, roll forming machine, cutting station, and discharge table."

According to the specifications of the required baffle ceiling, the production parameters are entered in the PLC control panel. After the switch is turned on, the baffle ceiling making machine starts to operate automatically, processes the coil to produce the width and height required by the customer, and finally cuts the material into the required length. The baffle ceiling machine has the advantages of high precision, fast forming speed, convenient operation, simple maintenance, and durability, and is widely used in the construction and decoration industry. |  |

1/ Main Components and Work Flow of Baffle Ceiling Machine

Decoiler: The steel coil is gradually unrolled and fed into the subsequent processing equipment.

Precision leveling machine: The strip or plate of a certain thickness is squeezed by the upper and lower rollers to achieve a flat effect.

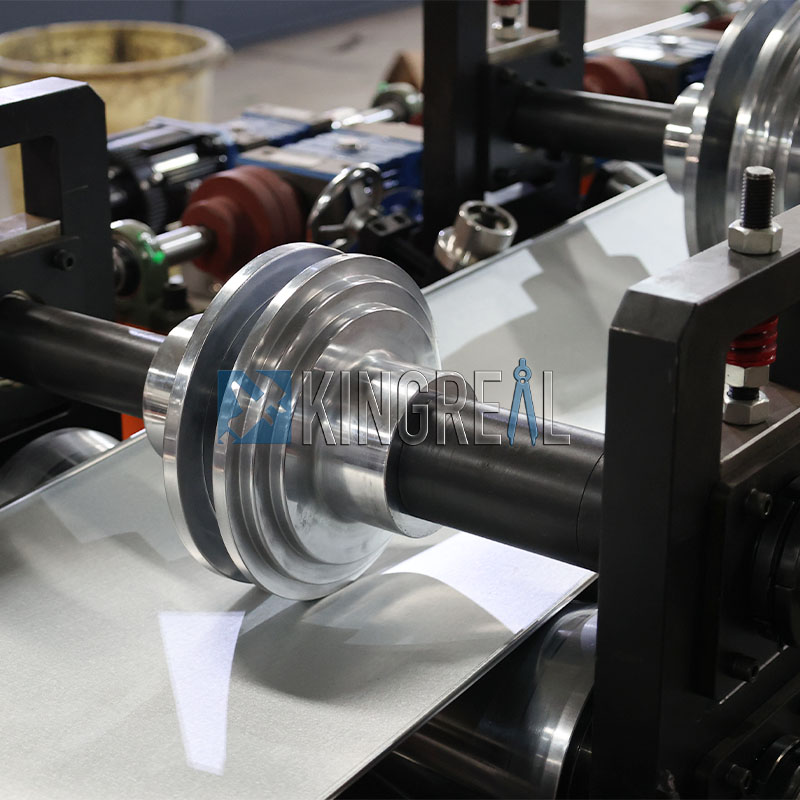

Roll forming machine: The metal strip is gradually formed through a series of rollers, and each roller performs a small incremental bend until the final contour is obtained.

Cutting station: Precise cutting according to the customer's preset length.

2/ Working Principle of Baffle Ceiling Machine

1. Feeding: Raw materials are fed into the baffle ceiling making machine.

2. Forming: Rolling and forming the metal coil.

3. Cutting: The baffle ceiling is sheared into the required length by the cutting station.

3/ Operating Procedures of Baffle Ceiling Machine

1. Preparation work

a. Make sure the baffle ceiling machine is in the shutdown state and disconnect the power supply.

b. Check whether the various parts of the baffle ceiling making machine are intact and clean the debris on the surface of the baffle ceiling machine.

c. Prepare the required raw materials and ensure that their quality meets the requirements.

2. Start the baffle ceiling machine

a. Connect the power supply correctly according to the instructions on the machine manual and turn on the power switch.

b. Start the baffle ceiling making machine according to the instructions on the machine manual and adjust the relevant parameters such as temperature, pressure, etc.

3. Processing operation

a. Put the raw materials into the feed port of the baffle ceiling machine and ensure that the feed port is well closed

b. Adjust the working mode and speed of the baffle ceiling making machine according to the product requirements.

c. Observe the working status of the baffle ceiling machine to ensure that no abnormal situation occurs during the product processing.

d. Regularly check the temperature, pressure and other parameters of the baffle ceiling making machine to ensure that they are within the normal working range.

e. If any abnormal situation or machine failure is found, stop the baffle ceiling machine immediately and report to the relevant personnel.

4. Finished product processing

a. After the baffle ceiling making machine completes the processing, take the finished product out of the discharge port and conduct necessary inspections.

b. Package and mark the finished product to ensure that the quality of the finished product meets the requirements.

c. Store or transport the finished product properly to prevent damage or contamination.

5. Shutdown and cleaning

a. After the processing is completed, shut down the machine in time and disconnect the power supply.

b. Clean the various parts of the baffle ceiling machine, including the feed port, discharge port, mold, etc.

c. Check whether the machine is loose, worn, etc., and repair or replace it in time if necessary.

4/ Baffle Ceiling Machine Maintenance

Maintaining the normal operation of the baffle ceiling making machine requires regular maintenance, including but not limited to:

1. Cleaning: Keep the surface and working area of the baffle ceiling machine clean, and regularly clean dust and impurities to prevent them from affecting the normal operation of the machine.

2. Inspection: Check every day whether the parts of the baffle ceiling making machine are tight and intact. If there is any looseness or damage, tighten or replace it in time.

3. Lubrication: Lubricate the lubrication points of the baffle ceiling making machine regularly to ensure smooth operation of the machine.

5/ Different Types of Baffle Ceiling Machine

In modern manufacturing, baffle ceiling making machines are important equipment for producing baffle ceilings and are widely used in the construction and decoration industry. As a baffle ceiling machine manufacturer with more than 20 years of experience, KINGREAL CEILING MACHINERY relies on rich industry knowledge and technical accumulation to design various types of baffle ceiling making machines according to different production needs and market research of customers to meet different processing needs.

1. According to the needs of different specifications

1.1 150mm height baffle ceiling machine

This baffle ceiling making machine is designed for the production of baffle ceilings with a height range of 35-150mm and a width range of 30-100mm. Its flexibility enables it to meet a variety of architectural and decorative needs, suitable for applications in various occasions, and ensures high efficiency and stability in the production process.

1.2 200mm height baffle ceiling machine

This baffle ceiling making machine is designed to produce baffle ceilings with a height range of 35-200mm and a width range of 30-100mm. Its wide range of applications makes it very competitive in the market and can meet customers' needs for diversified baffle ceiling specifications.

1.3 300mm height baffle ceiling machine

This baffle ceiling making machine is tailor-made by KINGREAL CEILING MACHINERY according to the special production needs of customer Douglas. It is specially used to produce baffle ceilings with a height range of 35-300mm and a width range of 50-100mm. Since the customer has a high requirement for the height of the baffle ceiling, the difficulty of forming also increases. KINGREAL CEILING MACHINERY engineers designed a hollow roller for it to ensure the smooth operation and forming quality of the baffle ceiling machine.

2. According to customer needs

2.1 Baffle ceiling machine with feeding trolley

In order to improve production efficiency and liberate manpower, KINGREAL CEILING MACHINERY has equipped the baffle ceiling making machine with a feeding trolley. This configuration can automatically convey large coils to the decoiler, greatly reducing the need for manual handling, increasing production speed, and ensuring quality and stability during the production process.

2.2 Protective shield for baffle ceiling machine

In order to ensure production safety and meet the requirements of some countries for machine safety devices, KINGREAL CEILING MACHINERY has designed a protective shield for the baffle ceiling making machine. When the machine is in operation, the protective shield can effectively prevent workers from being injured by accidentally touching the moving parts. After the baffle ceiling machine stops, workers can safely open the protective shield for daily maintenance and cleaning to ensure the long-term stable operation of the baffle ceiling making machine.

2.3 Baffle ceiling machine for producing u baffle with u bent

KINGREAL CEILING MACHINERY is committed to meeting customers' diverse needs for baffle ceiling types. For example, KINGREAL CEILING MACHINERY engineers can design a special baffle ceiling making machine that can produce u baffle with u bent based on the drawings provided by customers. This customized service not only demonstrates KINGREAL CEILING MACHINERY professional capabilities, but also reflects KINGREAL CEILING MACHINERY high attention and flexible response to customer needs.

Get the latest price? We'll respond as soon as possible(within 12 hours)