How to choose a metal perforated making machine?

2025-07-22 17:00

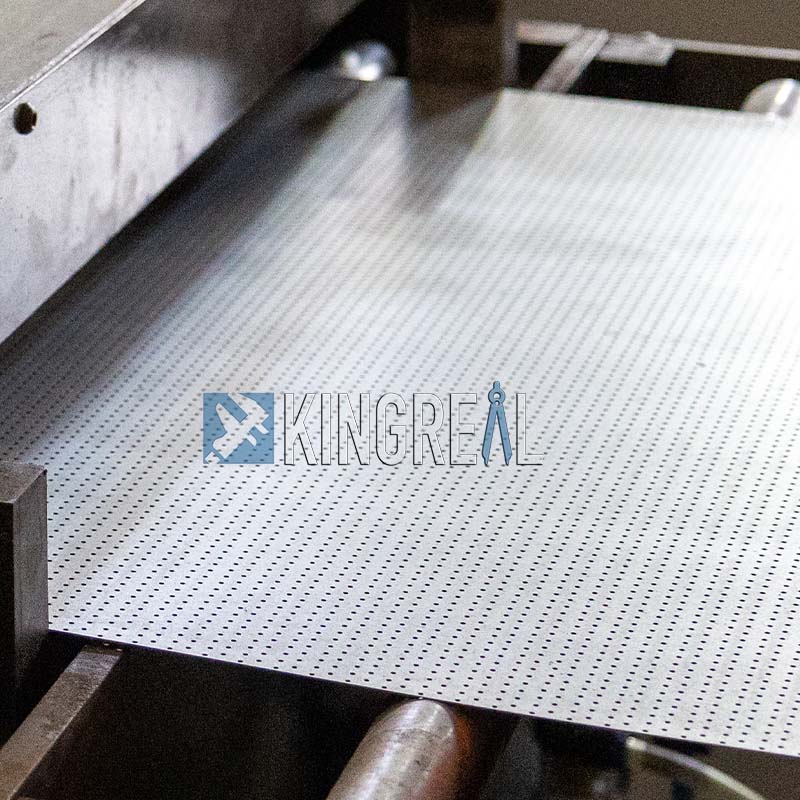

Metal perforated making machine is a mechanical device specially used to punch out different types of hole diameters and hole shapes on the surface of metal coils. It is widely used in various industries to produce perforated finished products suitable for subsequent processing.

These finished products can be used for a variety of purposes such as sound insulation, screw installation, filtration, etc., so they play a vital role in modern industry.

With the development of global manufacturing, the market demand for perforated metal machines continues to grow. Metal perforated making machines have received widespread attention in the United States, Brazil, Canada, Greece and other places.

Enterprises hope to improve production efficiency, reduce production costs and meet the diversified needs of the market through efficient and precise steel perforated machines. Therefore, it is particularly important to choose a metal perforated making machine that suits their production needs.

Considerations for Selecting Perforated Metal Machines

1. Clarify specific application requirements

First, customers need to clarify their specific application requirements, including metal type, required perforation mode and output. According to different needs, KINGREAL CEILING MACHINERY divides steel perforated machines into several major types:

Sheet metal perforation machine: used to accurately cut perforated metal coils according to preset lengths.

Coil to coil perforation line: Rewind the metal coil after punching for subsequent processing and long-distance transportation.

Metal ceiling tile perforation line: Specially used to produce perforated ceiling tiles to meet the needs of the construction and decoration industries.

In addition, customers need to specify the type of metal to be processed, such as iron plate, stainless steel plate, copper plate, aluminum plate and galvanized plate. Each metal material has different requirements for the metal perforated making machine, so it should be determined in advance. At the same time, it is also crucial to choose the right hole type. Common punching shapes include round holes, oblong holes, square holes, triangular holes, diamond holes, hexagonal holes and cross holes.

2. Production capacity of perforated metal machine

Production capacity is a factor that cannot be ignored when choosing a steel perforated machine. KINGREAL CEILING MACHINERY provides metal perforated making machines of different tonnages, including 120 tons, 125 tons, 160 tons and 200 tons. These punching machines of different tonnages have significant differences in production capacity, mainly depending on factors such as production speed, hole type, material width, material type and material thickness required by customers.

When evaluating production capacity, customers should consider the expected production scale and output. Different production scales have different requirements for the performance configuration of the perforated metal machine, so understanding and planning production capacity in advance will help choose the right steel perforated machine.

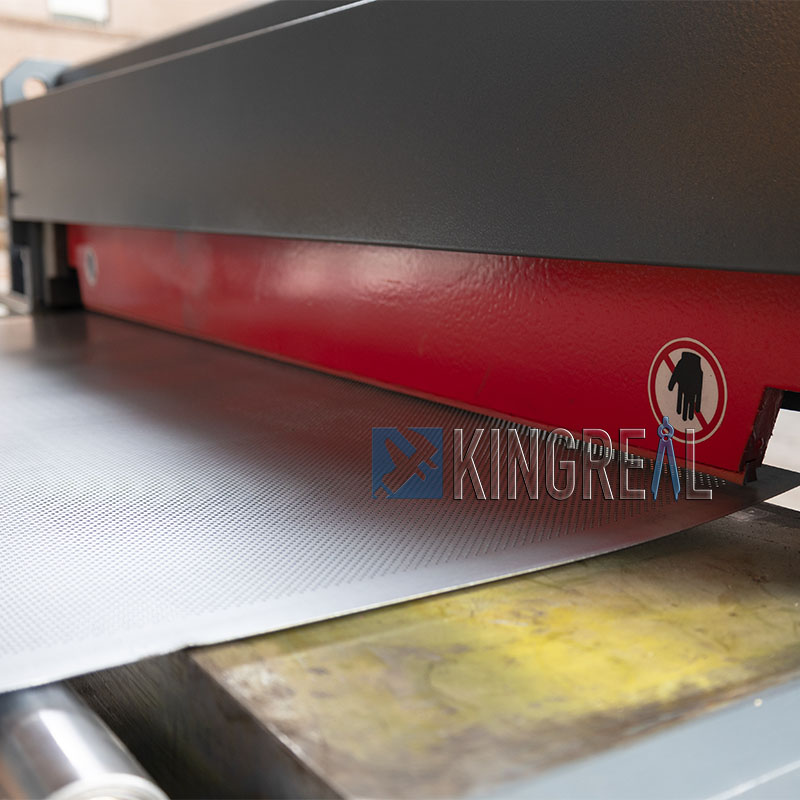

3. Safety features for metal perforated making machine

Safety in production is the primary consideration. When choosing a perforated metal machine, be sure to ask whether the selected steel perforated machine has safety devices. For example, KINGREAL CEILING MACHINERY perforated metal machine has a high safety performance design. During the punching process, if an unexpected situation occurs (such as someone approaching the punching machine), the operator can stop the metal perforated making machine at any time to ensure safety.

In the actual operation of the perforated metal machine, safety features are not only related to the reliability of the equipment, but also affect the safety of the workers. Therefore, it is crucial to choose a steel perforated machine with good safety performance.

4. Maintenance requirements for perforated metal machines

Metal perforated making machine purchase is only the first step, and subsequent routine maintenance cannot be ignored. Before purchasing a perforated metal machine, customers need to understand the maintenance methods of the machine and evaluate the difficulty and cost of maintenance. Good maintenance can extend the service life of the steel perforated machine and reduce the failure rate.

Regular inspection and replacement of worn parts, cleaning of perforated metal machine, and ensuring the normal operation of lubricating systems, for instance, all play essential parts of the maintenance procedure. Knowing maintenance needs will enable businesses to run the metal perforated making machine in daily operations efficiently.

5. Budget and expected return on investment

Choosing a perforated metal machine ultimately depends on understanding the budget and projected return on investment. Customers must have a firm understanding of their own financial ability, and KINGREAL CEILING MACHINERY engineers will design a suitable steel perforated machine production plan according on the budget of the customer. Good budgetary planning guarantees not only the steady acquisition of machinery but also offers enough financial security for upcoming manufacturing.

Customers can assess the performance, production efficiency, and maintenance costs of various metal perforated making machines when evaluating their return on investment. Companies can pick the most affordable perforated metal machine using scientific investment analysis, therefore giving them an edge in market rivalry.

Choosing a steel perforated machine is a complex and important undertaking that necessitates careful analysis of several issues. Steps to guarantee that the appropriate metal perforated making machine is chosen include clarifying particular application needs, assessing production capacity, paying attention to safety features, grasping maintenance requirements, and judiciously budget planning.

Professional steel perforated machine maker KINGREAL CEILING MACHINERY offers consumers advice and recommendations to help companies find the metal perforated making machine fit for them, support production, and run more effective operations. Consult KINGREAL CEILING MACHINERY if you have purchase needs or more queries regarding the buying of metal perforated making machine.

Get the latest price? We'll respond as soon as possible(within 12 hours)