What are the application of perforated sheet metal punching machine?

2025-07-12 17:00

The main function of the perforated sheet metal punching machine is to accurately punch and shear various metal coils, including iron plates, stainless steel plates, copper plates, aluminum plates, galvanized plates, etc., through precision components such as decoilers, precision leveling machines, metal punching machines and cutting stations.

Finally, these processed metal materials can be used for subsequent processing to manufacture products such as perforated wall panels and perforated filter elements. This sheet metal perforating machine is not only suitable for the manufacture of complex automotive parts, but also for the production of simple electronic products and household appliances, and can perfectly match various manufacturing needs.

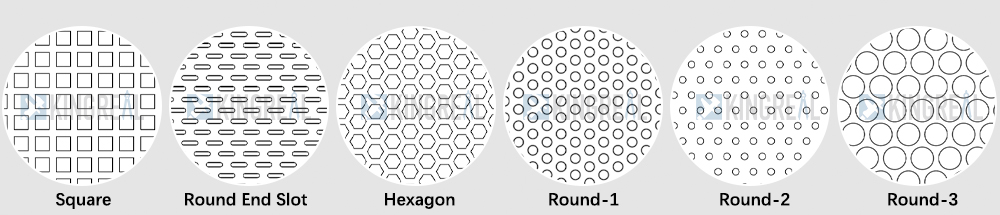

It is worth mentioning that the perforated sheet metal punching machine can meet customers' production needs for different hole types and apertures. For example, holes of various shapes such as round holes, oblong holes, square holes, triangular holes, diamond holes, hexagonal holes and cross holes can be easily realized. This flexibility makes the sheet metal perforating machine widely used in various industries.

Main Components of Sheet Metal Perforating Machine

Decoiler for perforated sheet metal punching machine

Decoiler is usually the first step to feed metal coils in the thickness range of 0.4-1.0mm into the sheet metal perforating machine. In order to ensure that the heavy metal coils can enter the decoiler smoothly, KINGREAL CEILING MACHINERY can equip the decoiler with a pressing arm to prevent the material from falling.

Precision leveling machine for perforated sheet metal punching machine

The precision leveling machine flattens the surface of the metal coil before punching to improve the accuracy of subsequent punching. The function of the precision leveler is to eliminate the warping and unevenness of the metal coil during the rolling process, so that each metal sheet can ensure the accuracy of the hole position when it passes through the punching, reduce the error in production, and improve the qualified rate of the product.

Metal punching machine for sheet metal perforating machine

The metal punching machine is one of the core components of the sheet metal perforating machine, which is responsible for punching out the hole type and hole diameter required by the customer on the metal surface. The punching die is customized according to the drawings provided by the customer. When there is a production demand for different hole types, you only need to replace the punching die to easily achieve a perforated sheet metal punching machine to punch out different holes. KINGREAL CEILING MACHINERY provides metal punching machines of different tonnages such as 125 tons, 160 tons and 200 tons to meet the needs of different customers in hole type, material width, type and thickness.

Cutting station for sheet metal perforating machine

The cutting station is controlled by a PLC control panel. The operator only needs to preset the length on the panel, and the system will automatically detect the length of the metal sheet and make precise cuts. This efficient design not only reduces the complexity of manual operation, but also improves the level of automation in production, ensuring product consistency and reliability.

Application of Sheet Metal Perforating Machines

Sheet metal perforating machine in construction industry

Perforated sheet metal punching machines are widely used in the construction industry to manufacture metal roofs and solid cladding. These perforated metal pieces ensure a perfect fit of all parts, reduce material waste, and improve the quality of customers' homes or offices. Punching holes in specific locations and sizes on the metal surface provides a solid foundation for the structure. These holes are usually designed to install screws or other connectors, ensuring the stability and safety of the building.

Perforated sheet metal punching machine in electronics industry

In the electronics industry, sheet metal perforating machines are used to manufacture housings and brackets to ensure the stability and firmness of all parts. The housing of electronic products needs to have good heat dissipation performance and structural strength, and punching technology just meets this need. Through precise punching, the housing of electronic products can effectively dissipate heat while reducing weight and improving the overall performance of the product.

Perforated sheet metal punching machine in aerospace Industry

In the aerospace industry, sheet metal perforating machines can produce lightweight and strong parts through their powerful punching capabilities. These parts must not only withstand extreme working environments, but also have excellent strength and durability. The flexibility of perforated sheet metal punching machines enables aerospace manufacturers to respond quickly to market needs and produce aerospace parts that meet high standards.

Sheet metal perforating machine in automotive Industry

In the automotive industry, perforated sheet metal punching machines also play an important role. Precision parts such as panels, brackets and structural parts of automobiles are manufactured by sheet metal perforating machines. Precision sheet metal punch cutting and forming are necessary to build complex designs and components used in vehicle assembly. Punching technology not only improves production efficiency, but also ensures high precision and high quality of automotive parts.

Optional Solutions for Sheet Metal Perforating Machine

In order to effectively improve the speed and efficiency of the entire production process and better meet customers' needs for automated production, KINGREAL CEILING MACHINERY can provide optional solutions for perforated sheet metal punching machines according to customer conditions. For example, if a customer has multiple production needs (both the winding and shearing of perforated coils are required), KINGREAL CEILING MACHINERY can equip the sheet metal perforating machine with a recoiler.

When the perforated coil needs to be rewound, just turn on the recoiler and the cutting station will automatically close; when the plate needs to be punched, just turn on the cutting station. Although the cutting station and the recoiler are on the same perforated sheet metal punching machine, they will not start at the same time.

Feeding trolley for sheet metal perforating machine

Equipping the decoiler with a feeding trolley can greatly improve production efficiency. Heavy coils no longer need to be manually transported to the decoiler, which liberates human resources, reduces labor costs, and reduces safety hazards caused by manual handling.

Metal metal sheet cleaning machine for sheet metal perforating machine

During the production process, oil stains may appear on the surface of the coil. In order to meet customers' high requirements for cleanliness, KINGREAL CEILING MACHINERY can equip the perforated sheet metal punching machine with a metal metal sheet cleaning machine. This equipment can clean the coil before punching, ensure product quality, and reduce the workload of subsequent cleaning.

Unloading trolley for perforated sheet metal punching machine

Equipping the recoiler with a trolley can automatically transport after winding, reducing the need for manual handling. This design not only improves production efficiency, but also ensures the safety of staff.

In summary, the sheet metal perforating machine is widely used in many industries such as construction, electronics, aerospace and automobiles due to its high efficiency, precision and flexibility. Through continuous technological innovation and equipment upgrades, the perforated sheet metal punching machine will continue to meet the growing production needs of the market and make greater contributions to the development of modern manufacturing.

Get the latest price? We'll respond as soon as possible(within 12 hours)