What are the advantages of steel perforated machine?

2025-07-08 17:00

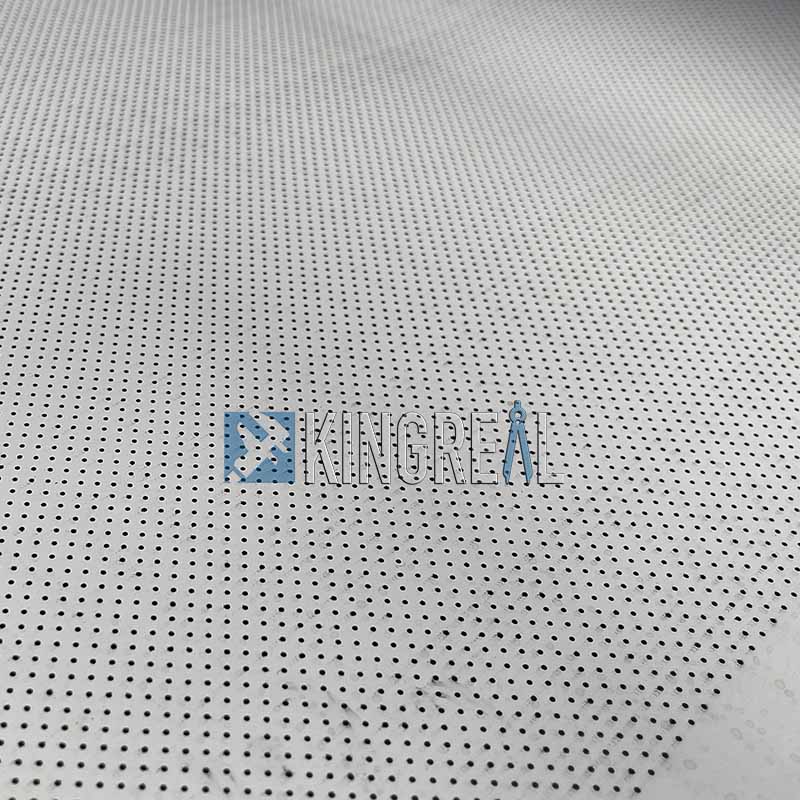

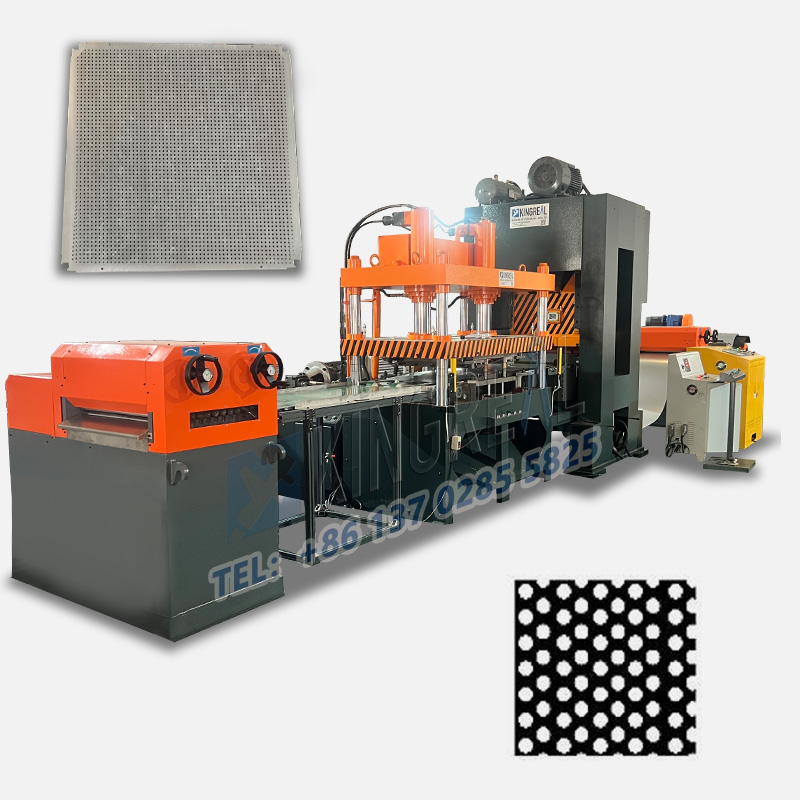

Steel perforated machine is a metal plate with uniform holes punched out on the surface of metal coils. Common hole types include round hole, long round hole, square hole, triangle hole, diamond hole, hexagonal hole, crossed hole, other special-shaped holes, etc. It is usually used in many fields such as filtration, ventilation, protection, and decoration.

Due to its strong corrosion resistance, durability, and beautiful appearance, it is widely used in construction, decoration, chemical industry, food processing and other industries. In this article, KINGREAL CEILING MACHINERY will introduce you to the four major advantages of perforated metal machine. If you need more information about steel perforated machine, welcome to consult KINGREAL CEILING MACHINERY!

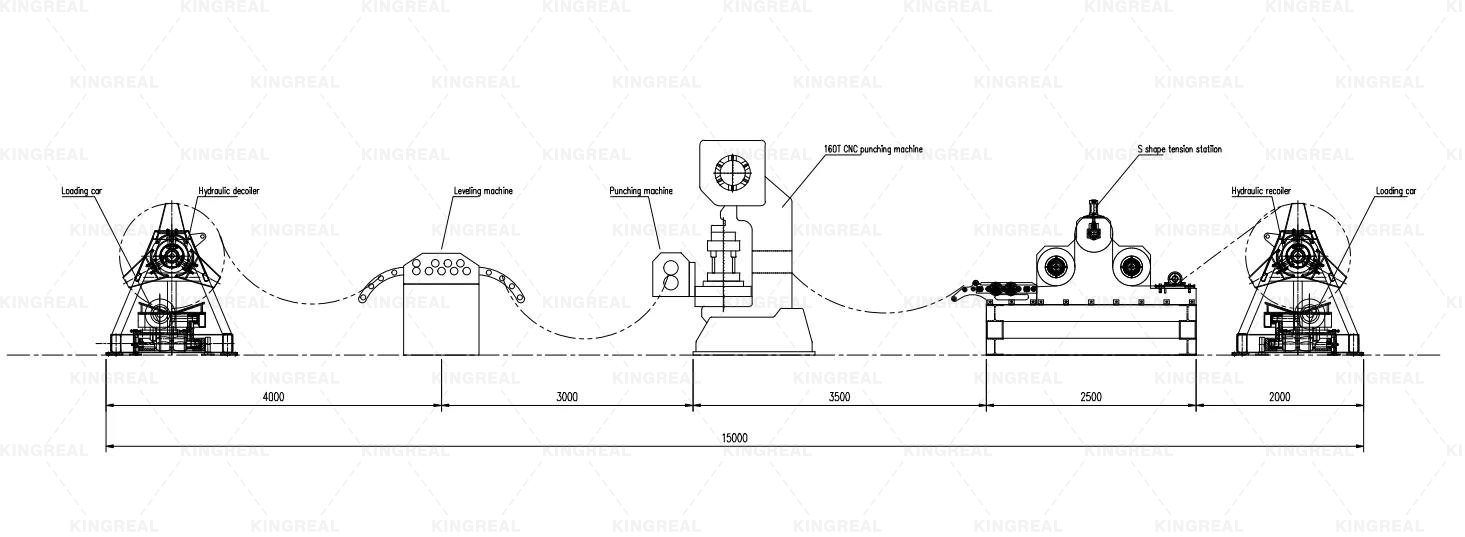

Working Process of Perforated Metal Machine

Decoiler -- Precision Leveling Machine -- Metal Punching Machine -- Cutting Station or Recoiler

Advantages of Steel Perforated Machine

1. Punching out 1.0mm micro holes

KINGREAL CEILING MACHINERY can provide customers with perforated metal machines that can punch out 1.0mm apertures.

The difficulty of producing micro holes lies in the requirement that the steel perforated machine has high precision and high stability, and more professional punching die design is required.

First of all, the dimensional accuracy of micro holes is extremely high, and any slight deviation may lead to product failure. To complicate matters further, the elastic deformation of the material during the punching process affects the shape and size of the hole, so the design of the punching mold must take into account the characteristics of the material and the processing conditions.

Secondly, the punching speed of the micro-holes also needs to be optimized. Too fast may cause the material to break, while too slow will affect production efficiency. In addition, the wear resistance and fatigue resistance of the punching mold are also key factors. High-strength materials must be used to manufacture the punching mold to ensure its stability in long-term use. KINGREAL CEILING MACHINERY has advanced equipment and an experienced team of engineers, which has solved the above-mentioned manufacturing difficulties of the perforated metal machine.

2. Processing 0.4-1.0mm thick metal coils

KINGREAL CEILING MACHINERY steel perforated machines can efficiently process metal coils with a thickness of 0.4mm to 1.0mm, which makes KINGREAL CEILING MACHINERY perforated metal machines widely used in a variety of industries. However, in the face of special thickness sheet processing needs, KINGREAL CEILING MACHINERY also provides personalized steel perforated machine manufacturing solutions.

For metal materials of different thicknesses, the design and configuration of the perforated metal machine will also be different. Thicker materials require stronger tonnage and higher punching capacity, while thinner materials can use relatively smaller equipment. KINGREAL CEILING MACHINERY encourages customers to contact us when they have special needs.

KINGREAL CEILING MACHINERY will provide customers with customized steel perforated machine solutions according to the specific situation to ensure high efficiency and high quality in the production process.

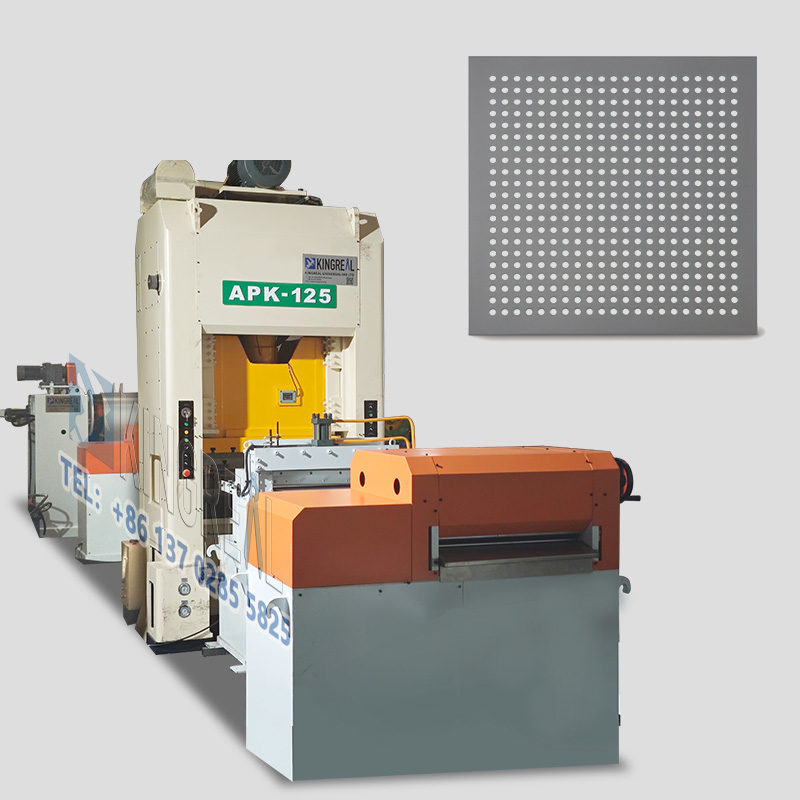

3. Different metal punching machine for steel perforated machine

KINGREAL CEILING MACHINERY is able to provide a variety of metal punching machines with different tonnages for steel perforated machines according to customer needs, including 120 tons, 125 tons, 160 tons and 200 tons. Choosing the right tonnage is not only about production efficiency, but also about the type, width and thickness of the material.

For example, usually for large width and thickness holes, 160 to 200 tons of punching machines are a more ideal choice. KINGREAL CEILING MACHINERY uses a set of scientific calculation formulas to help customers determine the required tonnage to ensure that the required hole shape can be punched out smoothly.

For different materials, the tonnage requirements of the metal punching machine will also change accordingly. KINGREAL CEILING MACHINERY professional team can make the most reasonable tonnage recommendations based on the drawings and production needs provided by customers, ensuring that customers can both ensure quality and improve efficiency during the production process.

4. Different types of perforated metal machine solutions

KINGREAL CEILING MACHINERY provides a variety of steel perforated machine solutions according to the customer's production process requirements, including metal sheet perforated machines, coil to coil perforation lines, and metal ceiling tile perforation lines.

4.1 Metal sheet perforated machine

On the metal sheet perforated machine, the metal coil can be accurately sheared by the equipped cutting station after the holes are punched. This process is particularly suitable for occasions where fixed-length products are required, such as mufflers, perforated wall panels, etc. Through precise shearing, customers can be more convenient in subsequent processing and improve production efficiency.

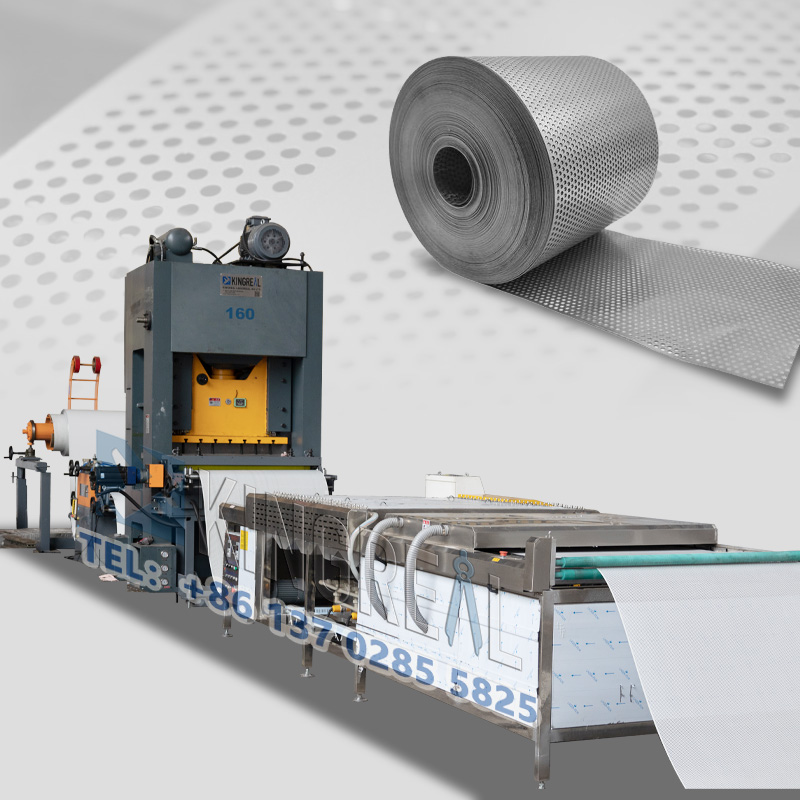

4.2 Coil to coil perforation line

The coil to coil perforation line is mainly used to wind up the metal coil after punching, which is convenient for subsequent long-distance transportation and surface protection. This solution is particularly suitable for the production of products such as bread trays and baffle ceilings. The design of the coil to coil perforation line makes the coil less likely to be damaged during transportation, thereby reducing material waste.

4.3 Metal ceiling tile perforation line

For customers who need to produce ceiling tiles, KINGREAL CEILING MACHINERY provides a metal ceiling tile perforation line. This production line is capable of producing various sizes and types of perforated ceiling panels, such as 30x30cm, 60x60cm and 60x120cm. Whether it is clip-in ceiling tile, lay-in ceiling tile or tegular ceiling tiles, KINGREAL CEILING MACHINERY metal ceiling tile perforation line can meet customer needs.

5. Flexible metal perforated making machine production plan

It is worth mentioning that KINGREAL CEILING MACHINERY steel perforated machine can be flexibly configured according to the different needs of customers. For example, customers may sometimes need a recoiler and sometimes a cutting station.

KINGREAL CEILING MACHINERY can equip the perforated metal machine with both components at the same time, and customers can easily switch through the control panel without having to purchase two additional steel perforated machines, the metal sheet perforated machine and the coil to coil perforation line. This flexibility not only saves customers time and money, but also reduces floor space and improves production efficiency.

Get the latest price? We'll respond as soon as possible(within 12 hours)