How does the omega channel machine work?

2025-07-06 17:00

Omega channel machine, also known as furring channel machine or hat channel machine, is a kind of equipment specially used for producing hat channel. This kind of omega channel is widely used in indoor construction projects such as factories, office buildings, large and medium-sized shopping centers, shopping malls and supermarkets to provide support for suspended ceilings. With the continuous development of the construction industry, the market demand for furring channel machine is becoming more and more vigorous, so it is particularly important to understand its working principle and main components. |  |

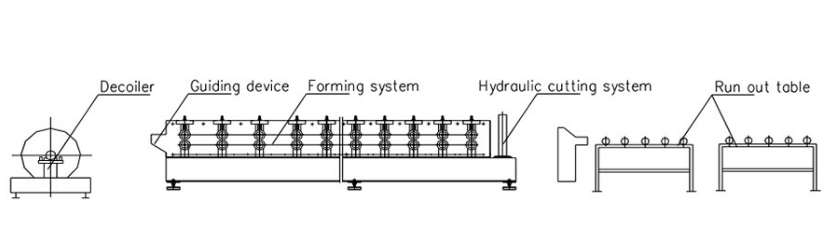

Working Process of Omega Channel Machine

Decoiler ↓ Roll Forming Machine ↓ Cutting Station ↓ Output Table |  |

Main Components of Furring Channel Machine

Decoiler for omega channel machine

Decoiler is an important part of furring channel machine, which can carry heavy metal coils and unwind them quickly. This component is designed to improve production efficiency and make the subsequent forming process smoother.

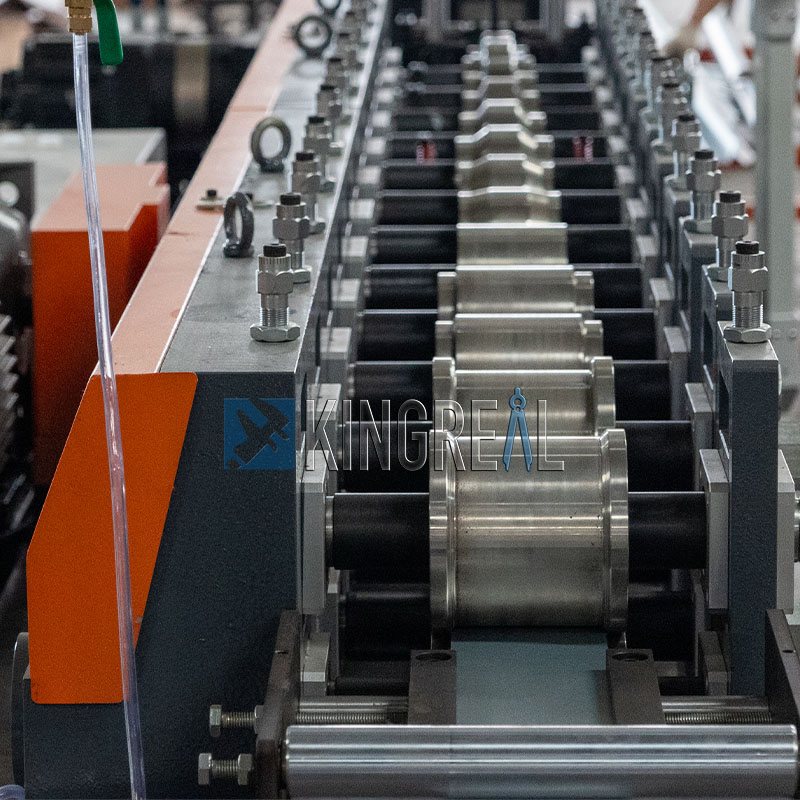

Roll forming machine for omega channel machine

The core component of furring channel machine is the roll forming machine. It is equipped with high-quality roller assembly, the main shaft diameter is φ75mm, and it is made of 45# round steel. The roller material is heat-treated, hard chrome-plated after fine turning, and mirror-polished. This design enables the roll forming machine to not only produce finished products of different sizes, but also maintain a high speed during the production process, up to 120 m/min. KINGREAL CEILING MACHINERY provides two solutions: roller replacement or hanger replacement to meet customers' production needs for finished products of different specifications.

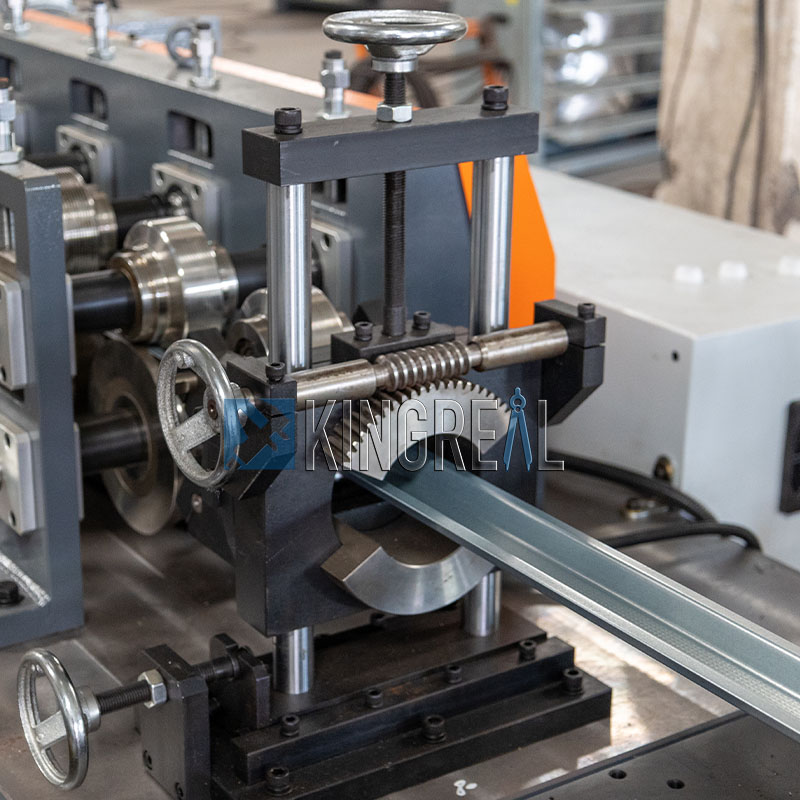

Cutting station for omega channel machine

The cutting station is an indispensable part of the furring channel machine. The station adopts a fully automatic follow shearing system, which has the characteristics of fast cutting and no noise when cutting. The cutter is made of Cr12Mov, and the shearing life exceeds 1 million times, ensuring long-term and stable production. At the same time, the rear scissor frame is made of Q235 steel plate, which is rough milled and annealed, and then finely processed to ensure that the cut is flat, burr-free and non-deformed.

Intelligent PLC control panel for omega channel machine

The furring channel machine is equipped with an intelligent PLC control panel, which is controlled by an industrial PLC computer. Users only need to enter production data on the control panel, and the omega channel machine can automatically complete the production requirements. This design not only improves the convenience of operation, but also reduces the skill requirements of operators, making the production process more humane.

Parameters of Furring Channel Machine

| Omega Channel Machine | |

| Material | GI Strip |

| Material Thickness | 0.4-1.3mm |

| Production Speed | Up to 120m/min |

| Shearing Accuracy | ±1.0mm/1m(There is a little deformation due to the material stress) |

| Straightness | Bending is less than 1‰/m,twist is less than 1.3%/m |

Optional Solutions for Omega Channel Machine

In order to better meet the personalized production needs of customers, KINGREAL CEILING MACHINERY provides a series of optional accessories for furring channel machines. Although these accessories are not necessary components of the omega channel machine, they can significantly improve production efficiency and product competitiveness.

Protective shield for furring channel machine

In order to ensure the production safety of workers and reduce safety hazards during work, KINGREAL CEILING MACHINERY has specially designed a protective shield. The protective shield can cover the roll forming machine when the omega channel machine is running to prevent workers from approaching and touching the running rollers. When the furring channel machine stops, the protective shield can be opened to clean and maintain the inside of the roll forming machine.

Customized roller or inkjet device for omega channel machine

KINGREAL CEILING MACHINERY furring channel machine can produce finished products with customer brand logo on the surface. This improves the market competitiveness of the finished products for customers. KINGREAL CEILING MACHINERY provides two solutions: the first is to install a roller with the customer's brand logo on the roll forming machine, and imprint the brand pattern on the metal profile during the forming process; the second is to install an inkjet device on the roll forming machine, and print the customer's required logo on the surface of the finished product while the finished product is being formed, eliminating the trouble of finding other machines or manual coding in the future.

Packaging unit for omega channel machine

After the finished product is produced, KINGREAL CEILING MACHINERY recommends equipping the omega channel machine with an automatic packing machine. This packing machine can realize one-stop automated production of inverted, bundled, and stacked, significantly improve overall production efficiency, and save labor costs and time.

Other Related False Ceiling Channel Machines

In addition to the furring channel machine, KINGREAL CEILING MACHINERY can also provide v-shape profile machines and main channel machines with different performance and parameters, providing customers with a complete false ceiling channel system.

As an efficient production equipment, the importance of the furring channel machine in the construction industry is self-evident. By understanding the work flow, main components, technical parameters and optional solutions of the

omega channel machine, we can more comprehensively understand its application value in modern construction. Whether it is high-efficiency production or safe and user-friendly design, the furring channel machine has demonstrated its leading position in the industry. If you want to know more about the parameters of the omega channel machine, please feel free to contact KINGREAL CEILING MACHINERY, we will serve you wholeheartedly!

Get the latest price? We'll respond as soon as possible(within 12 hours)