What is the purpose of u channel machine?

2025-07-01 17:00

U channel machine is an indispensable mechanical equipment in the modern construction industry, which is specially used to produce u channels of various sizes. This main channel machine is often used in conjunction with other false ceiling channel machines such as furring channel machine and wall angle machine to provide support structure for metal ceiling system. In this article, KINGREAL CEILING MACHINERY will discuss the workflow, main parameters, component composition and different options of u channel machine with you, and strive to present all aspects of this main channel machine to you. If you need more information about the parameters of this u channel machine, welcome to consult KINGREAL CEILING MACHINERY! |  |

Workflow of Main Channel Machine

Decoiler ↓ Main Roll Forming Machine ↓ Cutting Station ↓ Product Table |  |

Parameters of U Channel Machine

Profile | Material Thickness | 0.35-0.8mm |

| Material Type | GI | |

| Specification | U38x12mm | |

Decoiler | Coil Inner Diameter | Φ450mm-Φ530mm |

| Coil Outer Diameter | Φ1300mm | |

| Material Width Available | 20mm-300mm | |

| Max Carrying Capacity | 5tons | |

| Roll Forming Machine | Shaft Diameter | 40mm |

Components of Main Channel Machine

(1)Decoiler for u channel machine The decoiler is the starting point of main channel machine, responsible for unwinding the metal coil and feeding it into the main roll forming machine. The decoiler can carry metal coils with a maximum weight of 5 tons to ensure the efficient operation of the u channel machine. It is designed to achieve fast and efficient decoiling of metal coils. In addition to being able to carry a large weight, the decoiler is also equipped with an automatic feeding function to reduce the need for manual operation. |  |

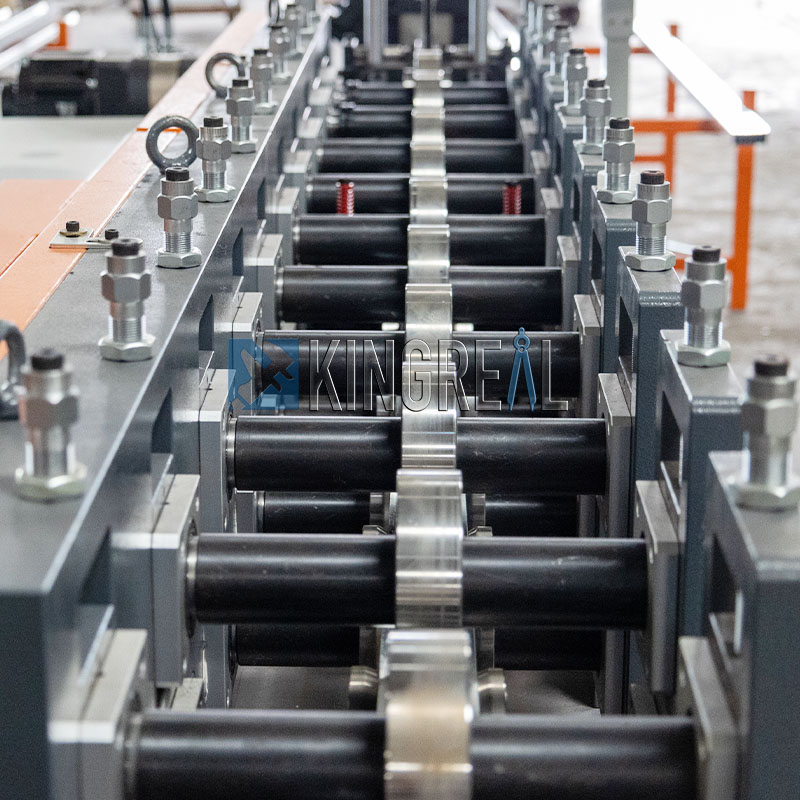

(2) Main roll forming machine for main channel machine The main roll forming machine is the core of the u channel machine. The main roll forming machine gradually forms the metal coil into a main channel through a series of rollers. The operator can enter the required size on the PLC panel, and the roll forming machine will automatically adjust the width of the rollers to meet the production needs of different lengths. If the height or width of the product needs to be changed, the operator can do it by replacing the rollers or hangers. In addition, the u channel machine runs very fast, up to 120 m/min, which greatly improves the production efficiency for customers. |  |

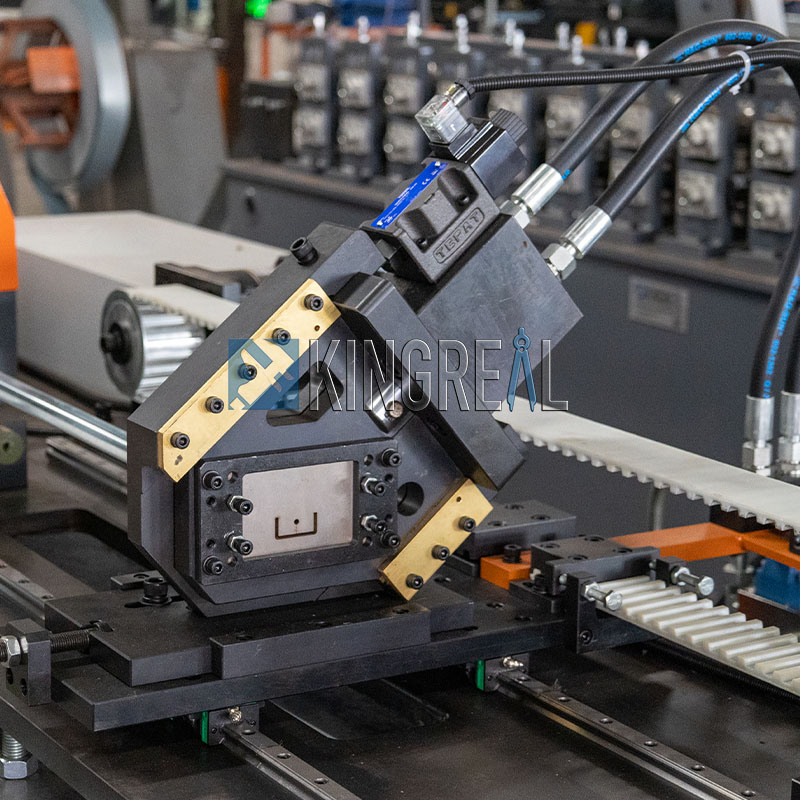

(3)Cutting station for main channel machine The flying shearing system used in the cutting station is a highlight of the u channel machine, which can perform fast shearing without stopping the main channel machine. The design of this system not only improves production efficiency, but also ensures the cutting accuracy of the finished product, maximizing customer satisfaction. |  |

U Channel Machine Manufacturing Solutions

Different customers have different production needs, so KINGREAL CEILING MACHINERY provides a number of different main channel machine manufacturing solutions for customers to choose from. These solutions select suitable components for the u channel machine based on the actual production situation of the customer. Here are several special main channel machine manufacturing solutions:

(1)Protective shield for u channel machine For some customers who have high requirements for production safety, the main channel machine can be equipped with a protective shield. When the u channel machine is running, the protective shield can effectively prevent workers from accidentally touching the operating parts of the main channel machine and reduce safety hazards. When the machine is turned off, the protective shield can be opened for daily maintenance and cleaning. |  |

(2)Auto packaging unit for u channel machine In order to improve work efficiency, the main channel machine can also be used in conjunction with an automatic packaging unit. The produced profiles will be automatically transported to the packaging machine for packaging and stacking, which not only saves labor costs, but also ensures the quality and neatness of the finished products, and facilitates subsequent transportation and storage. |  |

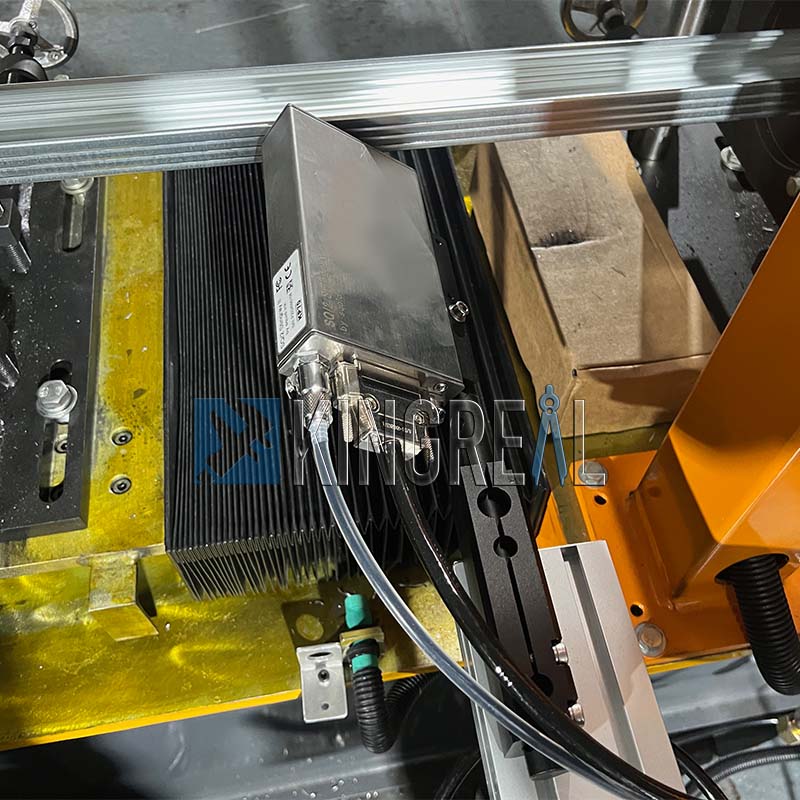

(3)Inkjet device for u channel machine During the forming process, the main channel machine can also be equipped with an inkjet device to print the customer's brand logo directly on the surface of the finished product. This design not only improves the market competitiveness of the finished product, but also saves the time and energy of finding a machine or manual spraying in the future. |  |

Product Display

KINGREAL CEILING MACHINERY u channel machinesuse advanced forming technology to ensure that the surface of the main channel is smooth. This feature not only improves the aesthetics of the product, but also effectively reduces the difficulty of subsequent processing and painting. The smooth surface reduces friction and reduces the risk of damage during transportation and installation. In addition, the smooth surface can better resist corrosion and extend the service life of the product.

And the high-quality materials and fine processing technology used by KINGREAL CEILING MACHINERY main channel machines make the u channel produced have excellent strength and durability. Whether it is carrying heavy objects or in harsh environments, these main channels can maintain good structural stability, thereby ensuring the safety and durability of the building.

U channel machine is an efficient and flexible production equipment in the modern construction industry that can quickly adapt to the needs of different customers. In the production process of building materials, the main channel machine has become the preferred equipment for major construction projects with its high speed, high precision and diverse solution options. Whether in large-scale construction projects or small-scale construction sites, u channel machine can provide customers with reliable support to ensure the smooth progress of construction.

Get the latest price? We'll respond as soon as possible(within 12 hours)