What is baffle ceiling machine?

2025-07-19 17:00

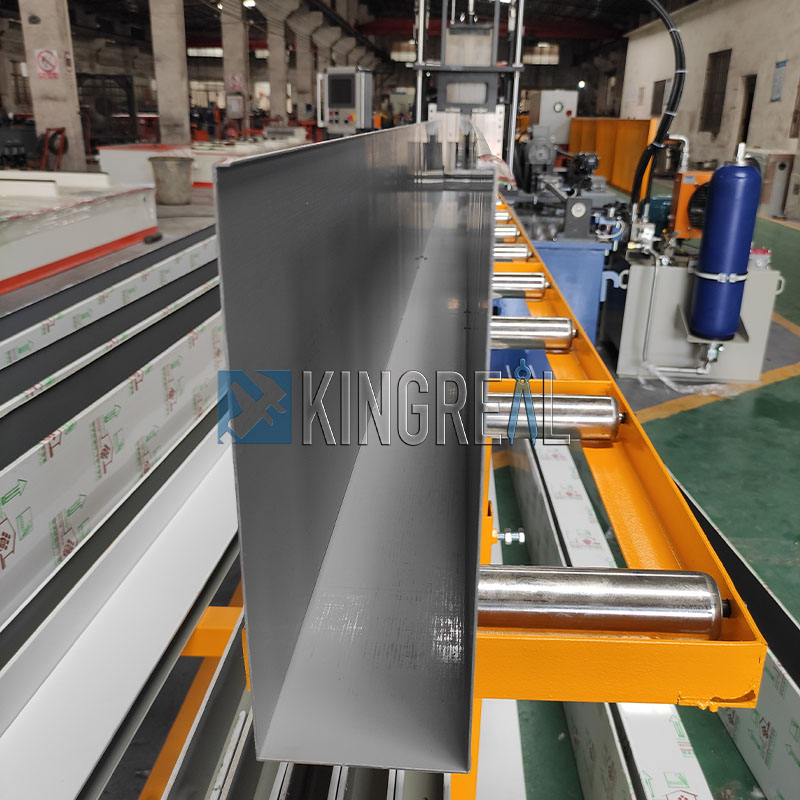

The baffle ceiling machine is an automated equipment used to produce baffle ceilings, which is widely used in the building decoration industry. It mainly uses 0.4-0.7mm iron plate or 0.3-1.0mm aluminum plate as raw materials, and forms baffle ceilings through a series of precision processes.

1/ Introduction to Baffle Ceiling Machine

The baffle ceiling produced by baffle ceiling machine processes include uncoiling, leveling, continuous rolling cold bending and cutting, etc., and finally produce products that meet the design requirements. The uniqueness of the baffle ceiling machine is that the height and width of its product section can be adjusted steplessly, and users can produce products of any size according to their needs.

The baffle ceiling making machine is easy to operate and uses NC numerical control adjustment. The operator only needs to enter the required product width, height and length on the touch screen, and other operations can be completed automatically by the baffle ceiling making machine. This efficient production method not only saves labor costs, but also greatly improves production efficiency, and the production speed can reach 30m/min. At the same time, the baffle ceiling machine is driven by an AC motor to ensure the stability and consistency of the production process. |  |

2/ Workflow of Baffle Ceiling Making Machine

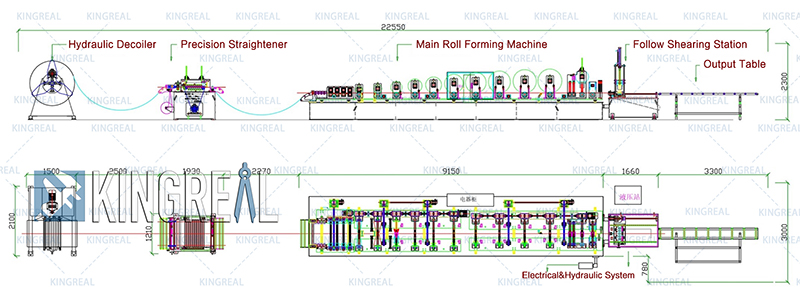

Decoiler -- Precision Leveling Machine -- Main Roll Forming Machine --Cutting Station -- Output Table

3/ Baffle Ceiling Machine Suitable Material Specification

| Materials | Aluminum, Steel, Iron, Galvanized Sheet, Roll-coated Sheet |

| Material thickness | 0.3-1mm |

| Profile width | 25-100mm |

| Profile height | 75-300mm |

| Profile specification | Same as drawing |

4/ Technical Data of Baffle Ceiling Making Machine

| Cutting Type | Follow Cutting |

| Operate Style | Automatic |

| Cutting Blade | Cr12MoV |

| Cutting Blade Material | Cr 12 High Grade Steel |

| Electric Power | 7.7KW (50HZ, 380V) |

| Production Speed | 30m/min |

5/ Advantages of Baffle Ceiling Machine

1. Meet the production needs of different types of finished products

KINGREAL CEILING MACHINERY baffle ceiling making machine can meet customers' production needs for different types of baffle ceilings. Common U-shaped baffle ceilings, V-shaped baffle ceilings, etc. have corresponding baffle ceiling machines to provide production.

In addition, KINGREAL CEILING MACHINERY has designed a baffle ceiling making machine for Vietnamese customers that can produce U-shaped baffle ceilings with u-bent, demonstrating its flexible adaptability to market demand.

2. Meet the production needs of finished products of different specifications

Through the PLC control panel, the operator can input the required baffle ceiling specifications, and the roller group of the roll forming machine will automatically adjust to produce finished products of different widths and heights.

The 150mm height baffle ceiling making machine, 200mm height baffle ceiling making machine and 300mm height baffle ceiling making machines launched by KINGREAL CEILING MACHINERY meet different production needs:

150mm height baffle ceiling machine: can produce height range 35-150mm, width range 30-100mm

200 mm height baffle ceiling machine: can produce height range 35-200mm, width range 30-100mm

300 mm height baffle ceiling machine: can produce height range 35-300mm, width range 50-100mm

3. Follow shearing system for baffle ceiling machine

KINGREAL CEILING MACHINERY has equipped the baffle ceiling making machine with a follow shearing system. The user only needs to preset the length on the PLC control panel, and the shearing station can cut the coil efficiently and accurately to ensure that the finished product is burr-free, flat and highly consistent.

4. Highly efficient baffle ceiling machine

This baffle ceiling making machine consists of a series of automated components such as decoiler, precision leveler, roll forming machine, shearing station, etc., which minimizes the need for manpower and improves production efficiency. Its production speed reaches 30m/min, which is suitable for large-scale production.

In addition, KINGREAL CEILING MACHINERY can also equip the baffle ceiling machine with a feeding trolley to eliminate the trouble of manual handling of heavy coils and further improve work efficiency.

5. Highly safe baffle ceiling machine

In order to meet customers' needs for production safety, KINGREAL CEILING MACHINERY can equip the baffle ceiling making machine with a protective shield to ensure the safety of operators. When the baffle ceiling making machine is running, the protective shield can effectively prevent workers from being injured by accidentally touching the running baffle ceiling machine. When the machine stops running, the protective shield can be opened for daily cleaning and maintenance.

6/ Different Baffle Ceiling Machine Manufacturing Solutions

1. Baffle ceiling machine & perforated metal machine

In addition to the baffle ceiling machine, KINGREAL CEILING MACHINERY also provides perforated metal machines to meet customers' production needs for perforated baffle ceilings. In the production process, the perforated metal machine first produces the coil with punched holes, then puts it into the baffle ceiling making machine, and finally produces the perforated baffle ceilings. This combination effectively expands the application range of the baffle ceiling machine and increases the diversity of products.

2. Baffle ceiling machine & baffle ceiling carrier machine

The baffle ceiling produced by the baffle ceiling making machine is combined with the baffle ceiling carrier produced by the baffle ceiling carrier machine to form a complete baffle ceiling system. The baffle ceiling carrier serves as a support to firmly fix the baffle ceiling on it, ensuring the structural stability and aesthetics of the baffle ceiling.

7/ Successful Project -- Baffle Ceiling Machine

As a baffle ceiling machine manufacturer with more than two decades of rich experience, KINGREAL CEILING MACHINERY has established a good reputation in the industry. With continuous technological innovation and high-quality customer service, KINGREAL CEILING MACHINERY baffle ceiling making machine products have been successfully shipped to Brazil, the United Kingdom, Mexico, Italy, Saudi Arabia, Qatar, Turkey, Russia and other countries and regions, serving the factory needs of different customers.

1. International Market Expansion

In the context of globalization, KINGREAL CEILING MACHINERY actively expands the international market and is committed to providing efficient and reliable baffle ceiling machine solutions to global customers. These baffle ceiling making machines not only meet the production needs of different countries and regions, but also make corresponding adjustments and optimizations according to the characteristics of the local market. For example, in Middle Eastern countries such as Saudi Arabia and Qatar, baffle ceiling making machines are used to produce high-quality building materials to match the rapidly developing local construction industry.

2. Customer Customization Service

KINGREAL CEILING MACHINERY is well aware that customers in different markets have different requirements for the performance and parameters of baffle ceiling making machines. Therefore, KINGREAL CEILING MACHINERY provides personalized baffle ceiling machine customization services to design the most suitable baffle ceiling machine according to the specific needs and production environment of customers.

For example, in Mexico, customers need to produce U-shaped baffle ceilings of specific specifications. KINGREAL CEILING MACHINERY engineers conducted a detailed demand analysis and finally provided a baffle ceiling making machine that fully meets the customer's requirements.

3. On-site installation and training

In order to ensure that customers can fully utilize the performance of the baffle ceiling making machine, KINGREAL CEILING MACHINERY engineers are not only responsible for the on-site installation of the baffle ceiling machine, but also provide professional machine operation training. Whether it is the factory in Italy or the production base in Brazil, KINGREAL CEILING MACHINERY engineers will go there in person to provide systematic training for the customer team.

4. Installation process

During the installation process, KINGREAL CEILING MACHINERY engineers will make detailed plans based on the customer's production line layout to ensure the best installation location and use efficiency of the baffle ceiling making machine. After the installation is completed, the engineer will conduct a comprehensive test of each component to ensure that the baffle ceiling making machine is in the best working condition before delivery.

5. Operation training

During the training session, KINGREAL CEILING MACHINERY engineers will explain to customers in detail the important knowledge of the baffle ceiling machine's operation process, maintenance and troubleshooting. Through practical exercises, customers' operators can quickly master the baffle ceiling making machine’s use skills, improve production efficiency, and reduce potential operating errors.

Baffle Ceiling Machine in Turky

Baffle Ceiling Machine in Italy

Baffle Ceiling Machine in Greec

Get the latest price? We'll respond as soon as possible(within 12 hours)