What is ceiling t bar machine?

2025-06-23 17:00

Introduction of Ceiling T Bar Machine

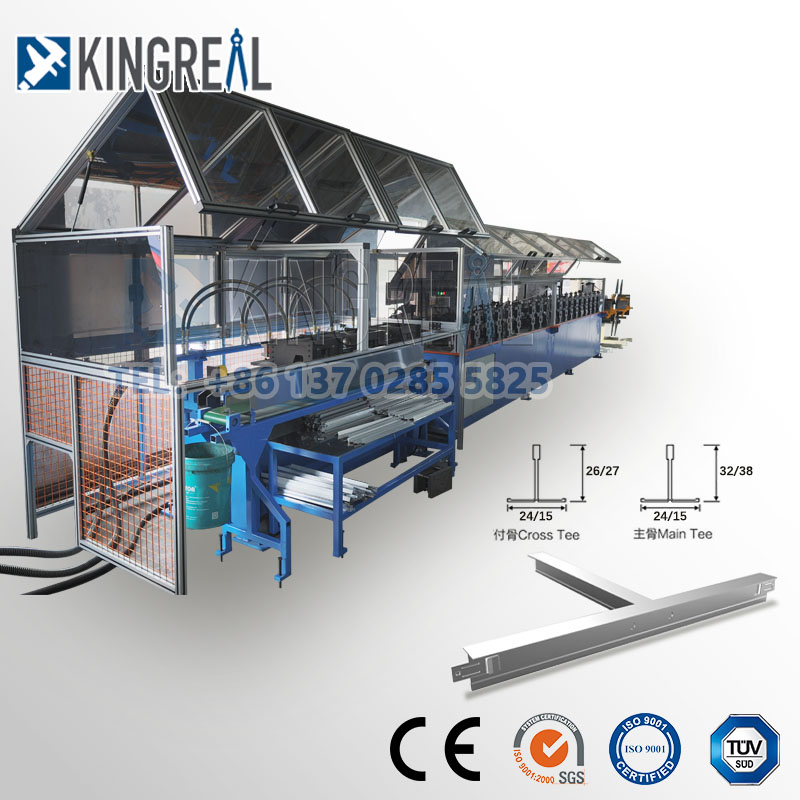

| KINGREAL CEILING MACHINERY ceiling t bar machine can produce main t, cross t and wall angle to support the metal ceiling panels. Usually the support of the suspended ceiling system consists of three different lengths of profiles, namely 600mm, 1200 mm cross t and 3600 mm main t. Of course, there are many other sizes on the market. Main t: The primary ceiling t grid that forms the main structure of the suspended ceiling system. Cross t: Smaller ceiling t bar that intersect with the main t, providing support for the metal ceiling tiles. Wall angle: Wall angle runs along the walls, forming the perimeter of the suspended ceiling tiles. KINGREAL CEILING MACHINERY can customize according to customer drawings and provide customers with ceiling t grid machines and wall angle machines that can produce various types and sizes of main or t grid. |  |

Workflow of Ceiling T Bar Machine

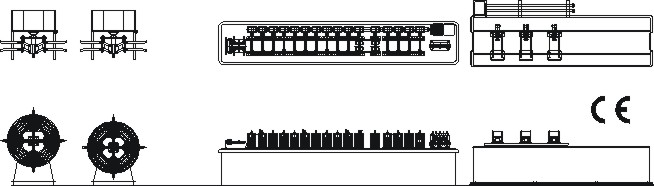

Hydraulic Decoiler ↓ Main Roll Forming Machine ↓ Punching and shearing station ↓ Product table |  |

Parameters of Ceiling T Grid Machine

| Ceiling T Bar Machine | ||

Decoiler | Weight | 150kg |

| Steel coil ID | 450~550(mm) | |

| Steel coil OD | 1500(mm) | |

Roll Forming Machine | Rollers | 14~18 Rows |

| Material: Cr12 | ||

| Inner diameter: 40mm: outer diameter:90 | ||

| Heat treatment hardness:HRC58-62 | ||

| Transmission | Chain and gear transmission | |

| Middle Plate | Steel plate thickness is 25mm | |

| Hydraulic System | Power | 7.5KW |

| Cutting System | Servo Tracking System | 2.2KW |

| Punching System | Material | SKD11 |

Main Components of Ceiling T Grid Machine

| Decoiler for ceiling t bar machine: The decoiler is the first important component of the ceiling t grid machine. It clamps the metal coil and feeds it into the machine for further processing. The decoiler can be manual or automatic, depending on the degree of automation of the ceiling t bar machine. |  |

| Roll Forming Machine for ceiling t grid machine: The roll forming machine is the core of the ceiling t bar machine. It consists of a series of rollers and forming dies that gradually form the metal strip into the desired ceiling t grid. The number and configuration of rollers depends on the specific ceiling t bar design. |  |

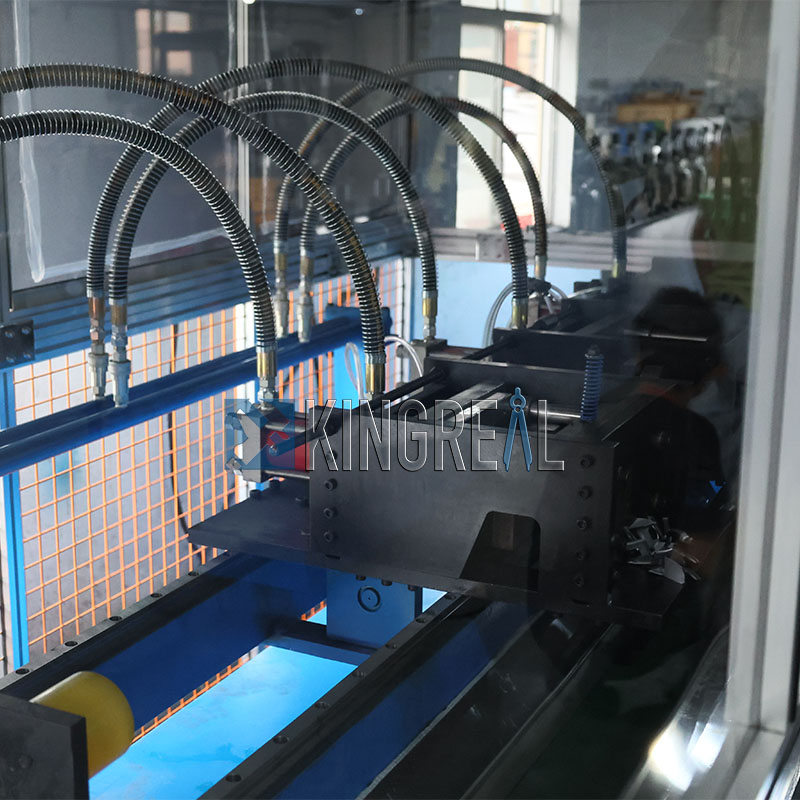

| Punching and shearing system for ceiling t grid machine: After the ceiling t grid is formed, it will be conveyed to the punching and shearing system. The hydraulic station equipped by KINGREAL CEILING MACHINERY provides punching and cutting power for the ceiling t bar machine. The main hydraulic station is used to punch the head lock hole and hole of the ceiling t grid, and is also used for quick cutting; the small hydraulic station moves the punching mechanism back and forth and applies the force required for quick cutting. Both hydraulic stations are controlled by an electrical PLC control cabinet. The main hydraulic station is equipped with an accumulator to ensure stable performance. KINGREAL CEILING MACHINERY is equipped with a flying punching and shearing system for the ceiling t grid machine, fully automatic punching and shearing, and punching and cutting can be completed in one step. |  |

Features of Ceiling T Bar Machine

(1) KINGREAL CEILING MACHINERY can provide different kinds of ceiling t bar machines to produce main t, cross t and wall angle. These ceiling t bar machines are manufactured by KINGREAL CEILING MACHINERY according to the actual specifications of the finished products and combined with the deeper needs of the customers. Therefore, KINGREAL CEILING MACHINERY can provide customers with ceiling t grid machines with excellent performance, long service life and fully matched with the production needs of customers. In order to improve the quality of ceiling t bar machines, KINGREAL CEILING MACHINERY not only independently develops PLC to ensure high precision, but also manufactures the punching molds of ceiling t grid machines in its own factory. (2) Multi-specification ceiling t bar machine. By flexibly adjusting the parameters of the ceiling t grid machine, the rollers of the roll forming machine can automatically adapt to different widths and sizes, so as to efficiently produce ceiling t grids of various specifications. In addition, the production speed of this ceiling t bar machine can reach up to 30m/min. This design makes the ceiling t grid machine extremely flexible and can meet the needs of different customers. It is suitable for a variety of engineering and construction scenarios. (3) Ceiling t bar machine with high safety performance. In order to help customers reduce the probability of safety hazards during the production process, KINGREAL CEILING MACHINERY specially designed a ceiling t grid machine equipped with a protective shield. The protective shield fully covers the roll forming machine, effectively preventing workers from accidentally touching internal components when the machine is running, thereby greatly reducing potential safety risks and ensuring the safety of operators and the smooth progress of production. (4) Technical upgrade of ceiling t bar machine. In order to effectively optimize the pressure and speed control during the forming process and improve the forming quality, KINGREAL CEILING MACHINERY equipped the ceiling t grid machine with a hydraulic oil cooler. The hydraulic oil cooler can effectively control the temperature of the hydraulic oil and prevent oil degradation caused by overheating, thereby extending the service life of the hydraulic system. And by keeping the hydraulic oil in a suitable working temperature range, it can ensure that the roll forming machine is operating efficiently and reduce the efficiency reduction caused by excessive temperature. |  |

Four Types of Ceiling T Bar Machine

The ceiling t grid machine is specially designed for the production of flat ceiling t, which can efficiently and accurately meet the needs of construction and interior decoration. This Flat Ceiling T Bar Machine uses advanced automation technology to ensure that the size and shape of the finished product are consistent, which not only improves production efficiency but also reduces material waste. Flat ceiling t are widely used in commercial and residential ceiling systems, providing a beautiful and neat visual effect for the space. |  |

2.Black Line Ceiling T Bar Machine The Black Line Ceiling T Bar Machine is specially used to produce black line ceiling t bar, which is suitable for modern interior design trends. This Black Line Ceiling T Bar Machine uses high-precision molding technology to ensure that each black line ceiling t grid can show perfect lines and smooth surfaces. Black line ceiling t grids can enhance the beauty and grade of the space in places such as high-end offices, art exhibitions and hotels, while providing designers with more creative inspiration. |  |

The ceiling t grid machine is specially designed for the production of FUT ceiling t bar and is suitable for special ceiling needs. This FUT T Grid Machine has flexible parameter adjustment functions and can quickly switch production modes according to different project requirements to ensure the diversity and adaptability of the finished product. FUT ceiling t grids are widely used in commercial spaces and public buildings, and can effectively support lighting and ventilation equipment and enhance overall functionality. |  |

4. Silhouette Ceiling T Grid machine The ceiling t bar machine is a device optimized for the production of silhouette ceiling t grids, which can achieve complex design requirements. The Silhouette Ceiling T Grid machine not only has efficient production capacity, but also maintains excellent product quality, ensuring that each finished product meets strict standards. Silhouette ceiling t bar are widely used in high-end commercial spaces and artistic environments, providing a unique visual effect for the design while enhancing the layering of the space. |  |

Get the latest price? We'll respond as soon as possible(within 12 hours)