How does a roller leveling machine work?

2025-09-06 17:00

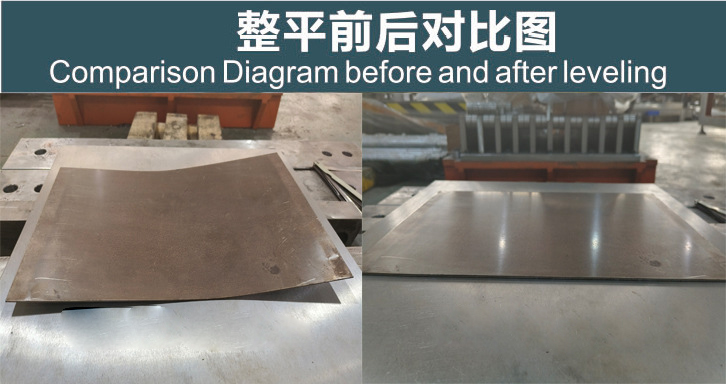

In sheet metal processing, precision roller levelers ensure the flatness of parts and sheets, eliminate residual stress, and improve product quality. Through precise rolling and reverse bending techniques, rollers leveling machines achieve the flattest possible flatness in sheet metal and reduce residual stress within the material. This article will explore in detail the operating principles, processes, and importance of precision roller levelers in sheet metal processing.

How Precision Roller Levelers Work?

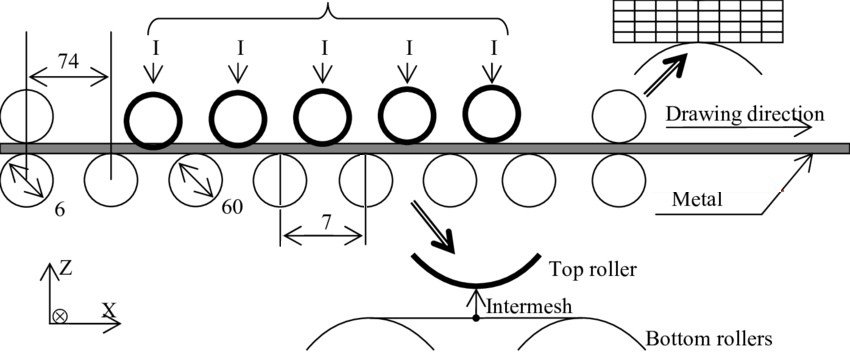

Roller leveling is a bending process that utilizes the motion of a rotating tool. More specifically, it is a type of roll bending. This process applies alternating bending and reverse bending (also known as elastic-plastic alternating bending) to the sheet metal, achieving the flattest possible flatness and reducing residual stress within the sheet metal.

During roller leveling, the material to be straightened (such as a blank or metal strip) passes through a series of staggered straightening rollers, which apply alternating upward and downward pressure. This process can be described as an outward-facing sine curve. The rollers leveling machine's feed needs to produce a curvature greater than the maximum curvature in the undirected state, while at the exit, the alternating curvature gradually decreases, allowing uneven sections to rebound to a flat state. The key to this process is overcoming the material's yield strength and ensuring that the straight profile maintains its original shape.

Sources of Residual Stress in Sheet Metal

Residual stress in the material typically arises from the following:

-Rolling: During the rolling process, residual stresses form within the material due to temperature changes and mechanical stresses.

-Mechanical and Thermal Separation: Processing operations such as cutting and welding impose stresses on the sheet metal, which can become residual stresses after the material cools.

-Thermal Effects: Temperature changes during heat treatment or welding can also cause stresses.

These residual stresses are often difficult to measure using nondestructive testing methods, but a nearly stress-free sheet metal is crucial for subsequent processing steps, especially welding. Therefore, effective straightening is crucial to ensure that workpiece quality is not affected by residual stresses.

Keys to Ensuring High-Quality Straightening

Consistent quality is crucial during roller leveling, requiring specific features and precision roller levelers types. For example:

-Modular Design: The modular design of the straightening unit allows for flexible adaptation to varying production requirements.

-Sturdy Frame: A stable rollers leveling machine requires an exceptionally sturdy frame to withstand the stresses applied during the straightening process.

-Appropriate Roller Gap: The roller gap (i.e., the distance between the rollers) must be maintained within an appropriate range to effectively reduce residual stress in the sheet.

-Number of Rollers: A sufficient number of rollers effectively improves flatness and ensures high-quality end products.

In practice, the upper and lower sets of straightening rollers require only two parameters to control the feed rate: feed rate and discharge rate. This means the distance between the rollers can be kept small, significantly reducing residual stress in the sheet.

Advantages of Precision Roller Levelers

As a mechanical process, roller leveling is the best way to achieve a flat and stress-free state in parts and sheets. Compared to manual straightening methods (such as hammer straightening, flame straightening, and press straightening), roller straightening offers several significant advantages:

-Efficiency: Rollers leveling machines can process large quantities of sheet metal in a short period of time, significantly improving production efficiency.

-Consistency: Precision roller levelers provides highly repeatable results, ensuring that each batch of products meets the same quality standards. Manual methods, which rely on experience, often produce inconsistent results.

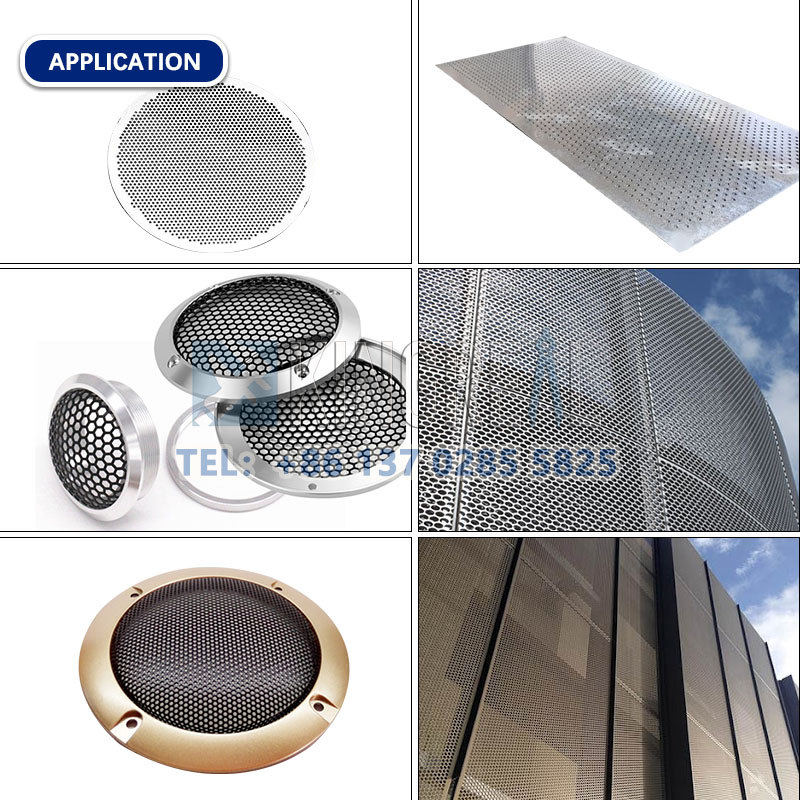

-Versatile: Rollers leveling machines can level a wide range of materials, including sheet metal, perforated metal, rods, and metal parts, to meet the needs of diverse customers.

-Powered Adjustment: Modern rollers leveling machines are often equipped with powered adjustment, allowing for easy adjustment of the gap and performance of the leveling rollers to suit the material's characteristics and production requirements.

Applications of Rollers Leveling Machine

Among others, precision roller levelers find extensive application in several fields including:

Rollers leveling machine in automotive manufacturing: Automotive manufacturing demands that several body parts be flat and stress-free in order for car safety and quality to be guaranteed.

Precision roller levelers in construction industry: Construction sector: Rollers leveling machines help to guarantee the structural stability of steel and other metal elements during the production of building materials.

Precision roller levelers in home appliance: Home appliance exterior and internal structures usually need leveling to guarantee both performance and looks.

Rollers leveling machine in aerospace: Part accuracy and strength are absolutely vital in the aerospace sector, and precision roller levelers assist produce aircraft components that meet exacting standards.

Get the latest price? We'll respond as soon as possible(within 12 hours)