Sheet Metal Straightener

KINGREAL CEILING MACHINERY offers a wide range of sheet metal straighteners designed to meet the flattening needs of metal sheets of varying thicknesses. These sheet metal straightening machines are categorized as heavy plate sheet metal straightener, thin plate sheet metal straightening machine, and standard sheet metal straightener, depending on the thickness and size of the sheet.

- KINGREAL CEILING MACHINERY

Details

Video About Sheet Metal Straightener

Description of Sheet Metal Straightener

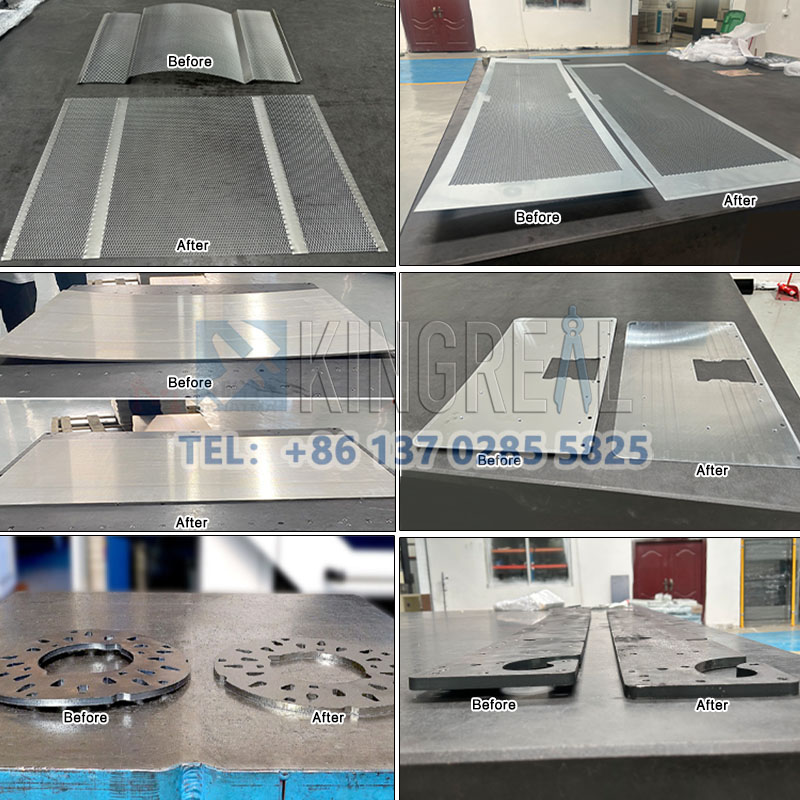

KINGREAL CEILING MACHINERY offers a wide range of sheet metal straighteners designed to meet the flattening needs of metal sheets of varying thicknesses. These sheet metal straightening machines are categorized as heavy plate sheet metal straightener, thin plate sheet metal straightening machine, and standard sheet metal straightener, depending on the thickness and size of the sheet. Thin plate sheet metal straightening machines are suitable for thinner, smaller sheet metal, while heavy plate sheet metal straighteners can handle extra-thick, oversized sheet metal. Whether it's hot-rolled or cold-rolled strip, or specialized materials like stainless steel, aluminum, and titanium, KINGREAL CEILING MACHINERY sheet metal straightening machines efficiently flatten the sheet metal.

KINGREAL CEILING MACHINERY sheet metal straightener manufacturing solutions for various thicknesses are designed to precisely correct the flatness and shape of coils and strips. These advanced sheet metal straightening machines require only one operator and are ideal for plate straightening, part straightening, metal cut to length lines, and other applications. KINGREAL CEILING MACHINERY sheet metal straighteners effectively address coil warpage, lateral bow, wavy edges, and center bow. |  |

Main Components of Sheet Metal Straightener

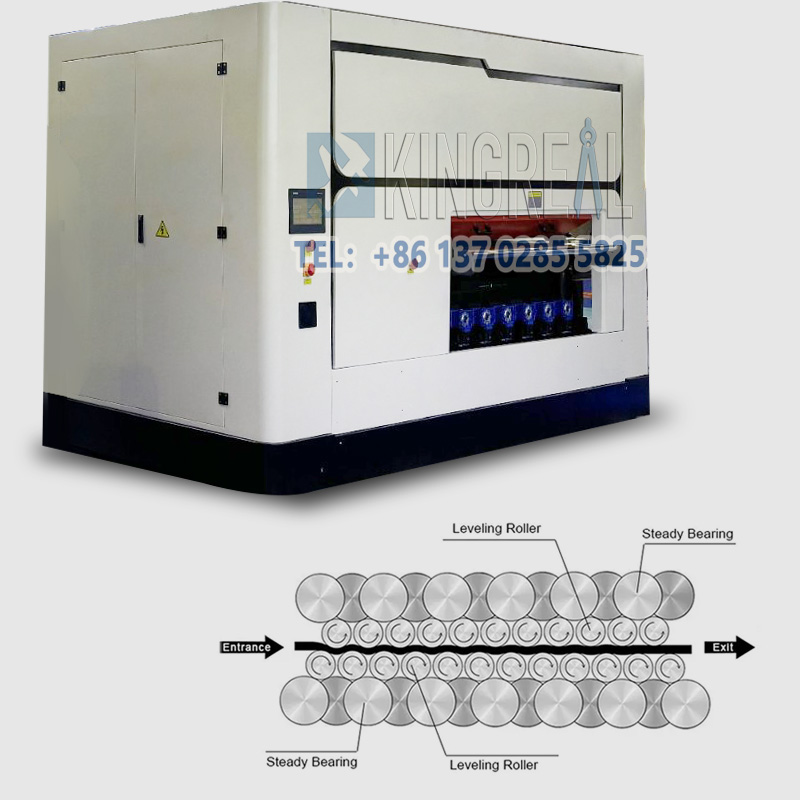

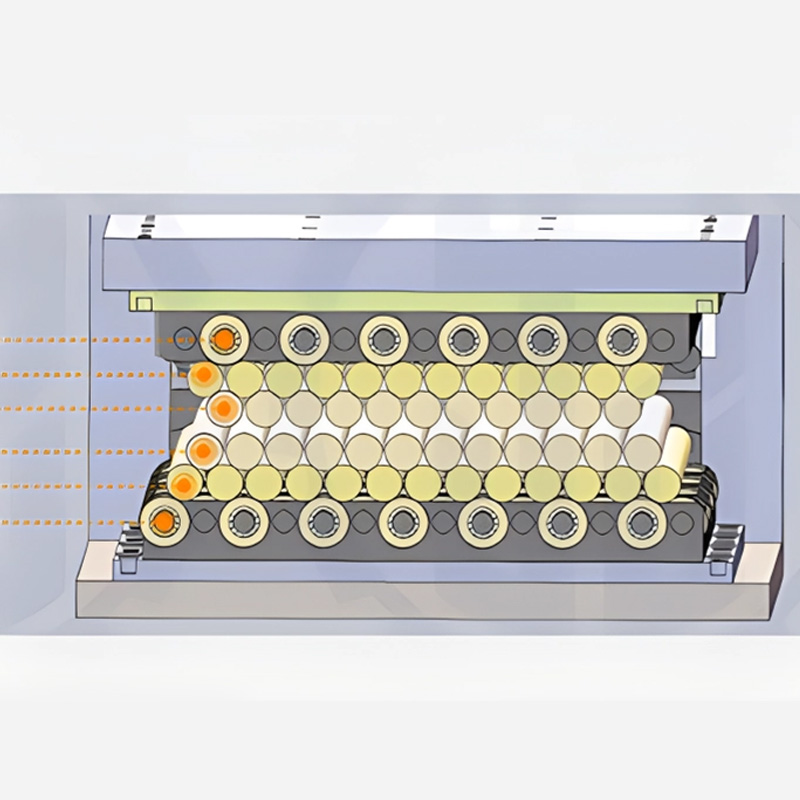

The core of a sheet metal straightening machine lies in the design and configuration of its main components:

| 1. Roller assembly for sheet metal straightener | The core of the sheet metal straightening machine is the roller assembly, which comprises many high-precision steel rollers. Ensuring the stability and reliability of the rollers is a smooth, high-hardness surface; some are hard-chrome plated for improved wear and corrosion protection. sheet metal straightener for long-term usage. |

| 2. Drive system for sheet metal straightener | Usually comprising a motor, reduction, coupling, chain, and sprocket, the drive system transfers energy to the rollers. It guarantees smooth material movement and prevents superfluous damage during the leveling operation by means of uniform and steady roller speed. |

| 3. Adjustment mechanism for metal sheet straightener | The space and pressure between the rollers is exactly regulated by the adjustment mechanism. Mechanical adjustment tools including hand-wheels, lead screws, and nuts allow the operator to set the rollers to match the thickness and characteristics of the material reaching the best leveling output. |

| 4. Frame for sheet metal straightening machine | The frame provides stable support for the sheet metal straightening machine and is typically welded from high-strength steel to prevent vibration during operation and maintain accurate leveling. |

Why Are There Demands for Sheet Metal Straightener of Varying Thicknesses?

Each manufacturer's project requirements vary, as do the thickness and type of materials they process. Consequently, their requirements for sheet metal straightening machines are also unique. Varying metal sheet thicknesses need appropriate sheet metal straightening in order to get best leveling results. Generally treating thicknesses between 0.2mm and 2.5mm are sheet metal straightening machine. Standard sheet metal straighteners often fail to provide best leveling results for materials under 0.2 mm thick requiring great flatness. Using a precision sheet metal straightening machine, moreover, when the material thickness exceeds 2.5mm may harm the rollers of the equipment, therefore compromising the leveling impact.

Moreover, different sheet metal straightener designs can generate different degrees of leveling effects when used to treat materials of the same thickness but several widths. For instance, materials with a maximum width of 100mm might be appropriate for a precision sheet metal straightening machine, but not for those with a thickness of 2.5mm. Users have to properly evaluate the material thickness and width when choosing a sheet metal straightener to guarantee the long run of the sheet metal straightening tool and best leveling outcomes.

Sheet Metal Straightener for Different Thicknesses

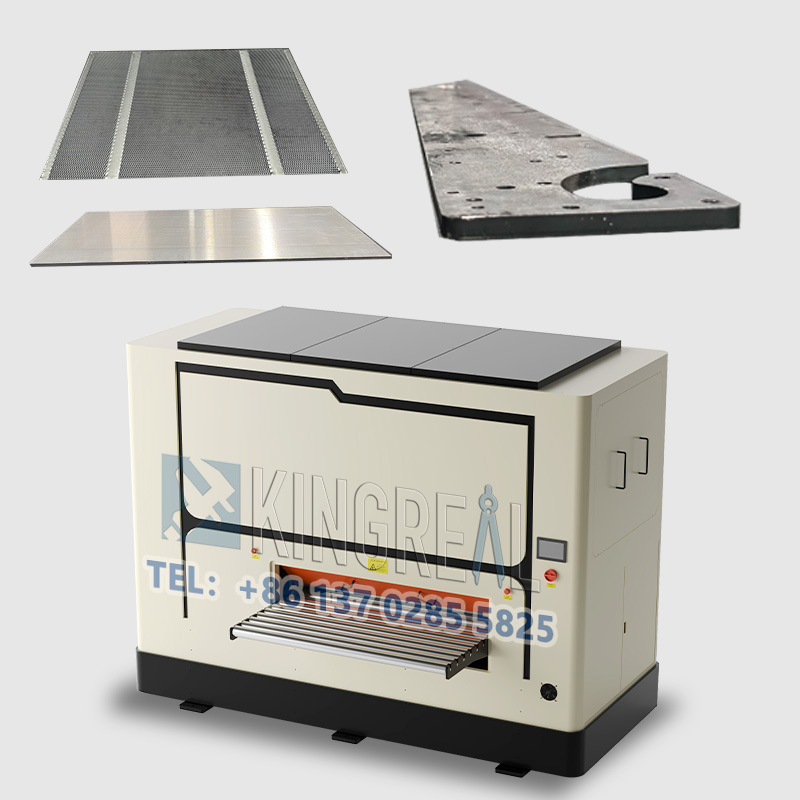

1. Thin plate sheet metal straightener Material thicknesses of 0.05mm to 0.5mm are best suited for thin plate sheet metal straightening machines. Thin stainless steel sheets, mobile phone component shields, frames, antennas, shafts, and precision hardware components for many digital products are among their main uses. For pre-stamping leveling, this kind of sheet metal straightener is great since it guarantees that the shape and flatness of the material reach very demanding levels.

2. Medium plate sheet metal straightener Medium plate sheet metal straightening machines are suitable for material thicknesses between 0.5mm and 3.0mm. They are widely used for pre-stamping leveling of hardware components with less stringent flatness requirements, such as automotive parts, mechanical components, and electrical housings. Designed with a balance of efficiency and quality, these sheet metal straighteners meet the production needs of medium-thickness materials.

3. Thick plate sheet metal straightener Thick plate sheet metal straightening machines are suitable for material thicknesses ranging from 1.0mm to 6.0mm. They are capable of pre-pressing thick plate materials such as automotive hardware, fasteners, caster hardware, and kitchen and bathroom hardware. Designed for high-intensity industrial applications, these sheet metal straighteners maintain excellent leveling results under the most demanding conditions. |  |

Sheet Metal Straightener Technology - Adjustable Roller Design

KINGREAL CEILING MACHINERY metal sheet straightening machines typically feature an adjustable roller spacing design. By adjusting the gap between the rollers, the sheet metal straightener can accommodate sheet metal of varying thicknesses. For example, with thinner sheets, the roller spacing can be reduced to minimize deformation; with thicker sheets, the roller spacing can be increased to ensure sufficient leveling force. However, there are limits to the roller spacing adjustment. |  |

Customized Sheet Metal Straightener Manufacturing Solutions

KINGREAL CEILING MACHINERY engineers can provide customized sheet metal straightening machine manufacturing solutions based on our customers' specific needs. The following are key points that KINGREAL CEILING MACHINERY engineers discuss with customers before designing a sheet metal straightener:

1. Thickness range for sheet metal straightener Different sheet metal straightening machine models have significantly different thickness ranges, making it crucial to select the appropriate sheet metal straightener for efficient production.

2. Material properties for sheet metal straightener Material properties such as hardness, elasticity, and ductility are key factors influencing the suitability of a sheet metal straightening machine. For example, for soft materials like aluminum and copper, the leveling force must be controlled to avoid deformation caused by excessive flattening. For hard materials like stainless steel and high-strength steel, the sheet metal straightening machine must have sufficient leveling force.

3. Processing precision requirements for sheet metal straightener Select the appropriate sheet metal straightening machine model based on your production needs. For example, for ordinary construction steel, a 7-9 roller mechanical model is recommended, while for precision stamping parts, a 17-roller or higher CNC model is recommended.

4. Production efficiency for sheet metal straightener For continuous production lines, it is recommended to configure automatic loading and unloading devices to reduce downtime and improve overall production efficiency.

5. Additional features for sheet metal straightener For precision machined parts, the sheet metal straightening machine can also be equipped with a deburring device and an online inspection system to monitor flatness in real time, reducing scrap and improving production quality. |  |

Application of Sheet Metal Straightener

Sheet metal straighteners are mainly used for straightening various specifications of sheet metal and sheared sheet metal into blocks. They feature advanced technology, high leveling precision, a wide processing range, high automation, and good reliability under high stress. These sheet metal straighteners are suitable for leveling various metal sheets, including stainless steel, aluminum, iron, cold-rolled, and hot-rolled metals. Due to their ease of operation and simplicity, sheet metal straighteners are widely used in various industries such as machinery, metallurgy, and building materials, and are particularly indispensable in the automotive, construction, manufacturing, and electronics industries.

FAQ About Sheet Metal Straightener

1.What is a sheet metal straightener?

2.What are the application of metal straightener machine?

3.What can a metal sheet straightening machine do?

4.What's working principle of sheet metal flattening machine?

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)