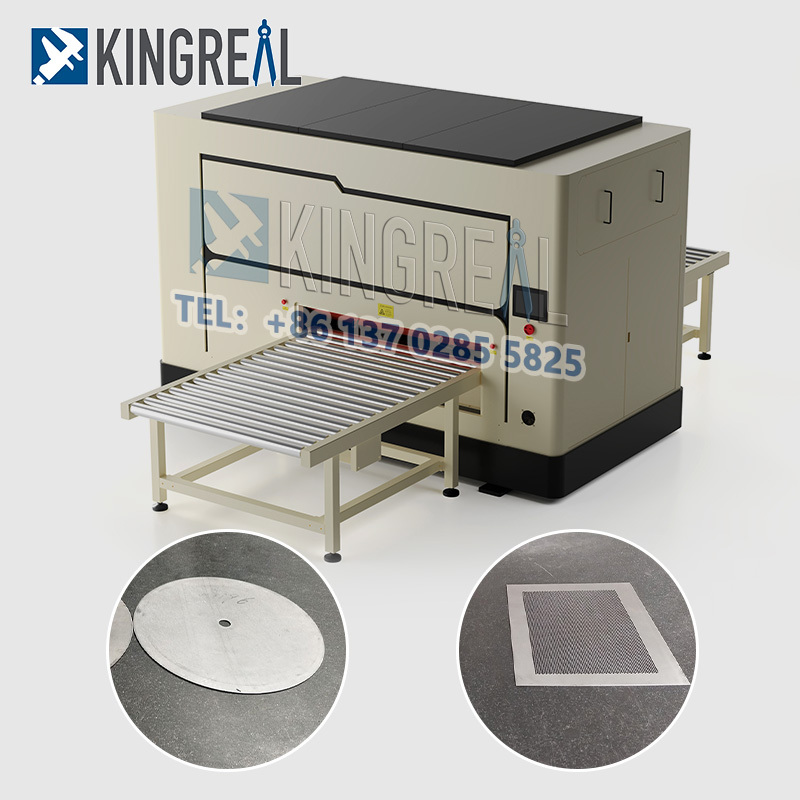

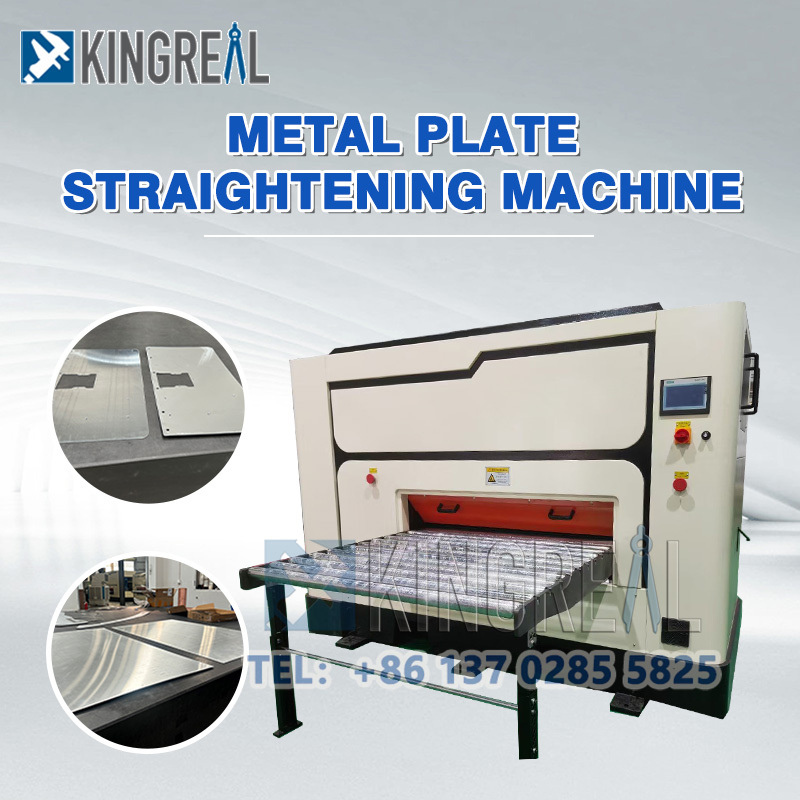

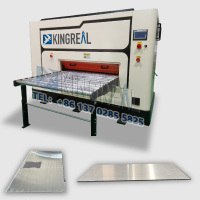

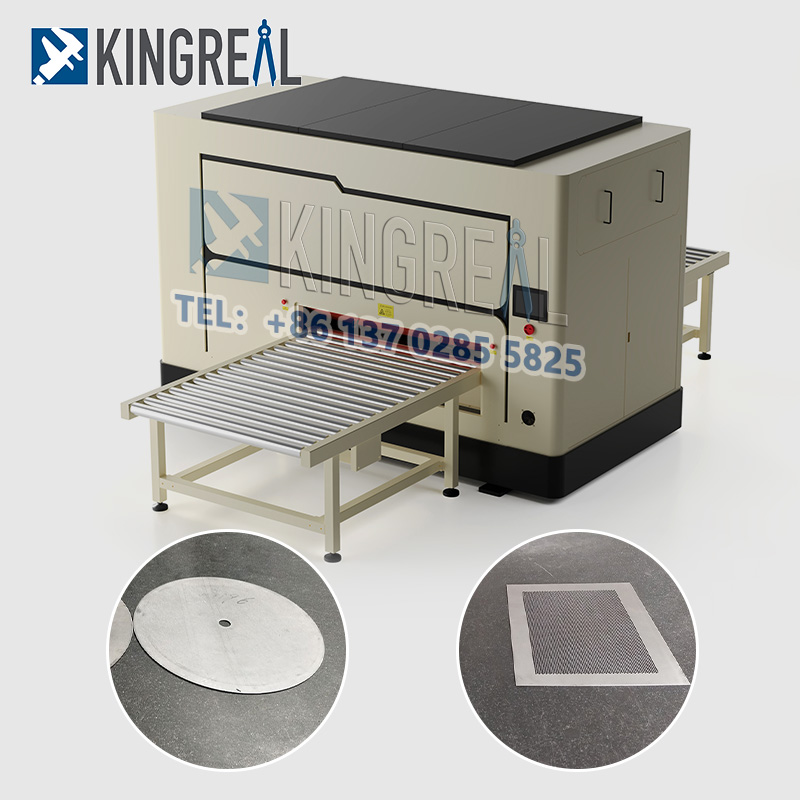

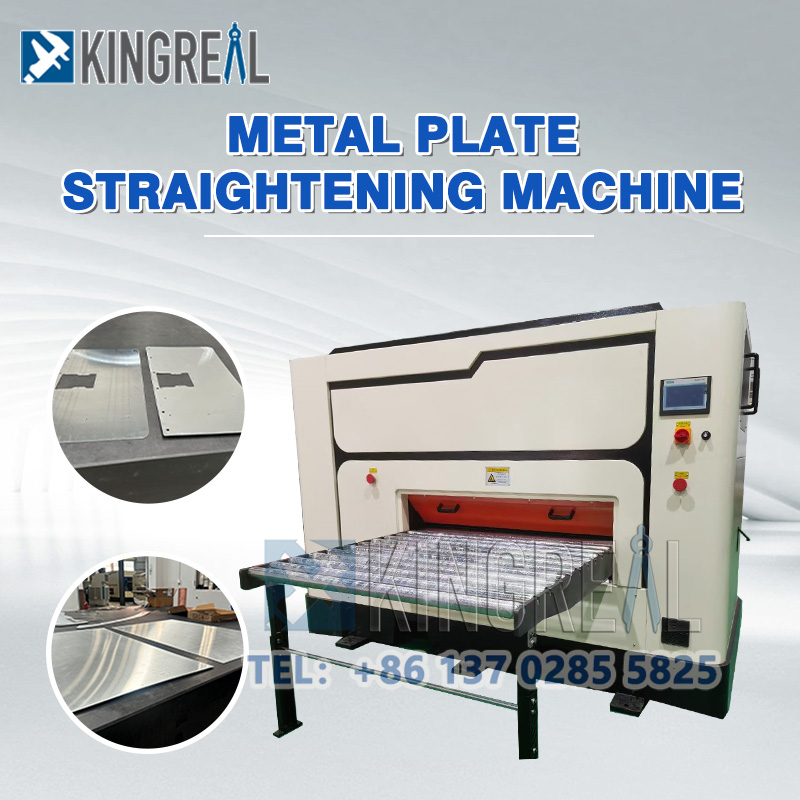

Metal Plate Straightening Machine

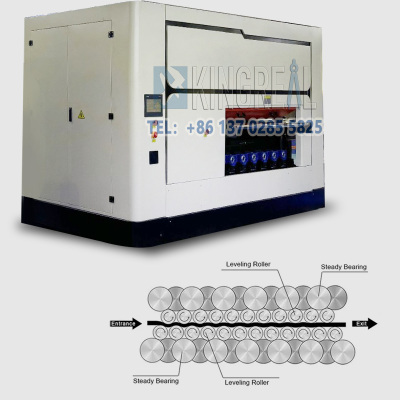

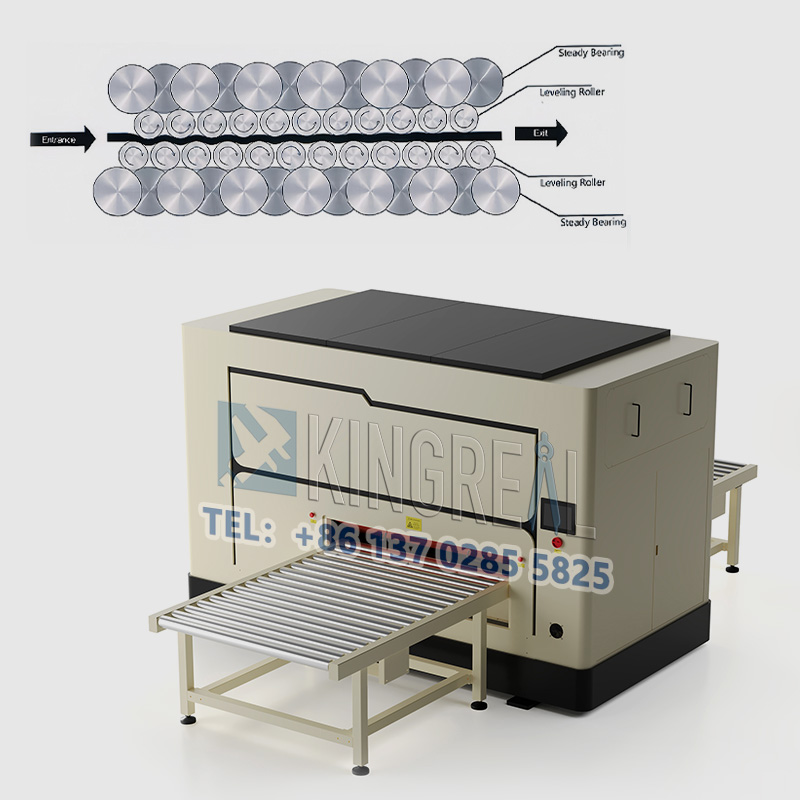

KINGREAL CEILING MACHINERY metal plate straightening machines are specifically designed for leveling metal materials. These sheet metal straightening machines are equipped with multiple sets of leveling rollers and support rollers, arranged in multiple layers with extremely close spacing between them. As the metal blank passes through the leveler, the "Bausinger effect" causes repeated twisting of the metal blank, gradually aligning the metal fibers, eliminating internal stresses, and restoring and improving the workpiece's flatness.

- KINGREAL CEILING MACHINERY

Details

Video About Metal Plate Straightening Machine

Description of Metal Plate Straightening Machine

KINGREAL CEILING MACHINERY metal plate straightening machines are specifically designed for leveling metal materials. These sheet metal straightening machines are equipped with multiple sets of leveling rollers and support rollers, arranged in multiple layers with extremely close spacing between them. As the metal blank passes through the leveler, the "Bausinger effect" causes repeated twisting of the metal blank, gradually aligning the metal fibers, eliminating internal stresses, and restoring and improving the workpiece's flatness.

KINGREAL CEILING MACHINERY offers a variety of metal plate straightening machines for precision metal plates. These sheet metal straightening machines consist of precision components such as a PLC, HMI, servo motor, servo drive (for electrically adjusting the leveling roller gap), and a frequency converter-driven main motor. Users simply set the leveling parameters on the HMI main interface, and the leveling roller gap is automatically adjusted. This highly intelligent and easy-to-use system significantly improves production efficiency.

Introduction to Metal Plate Straightening Machine

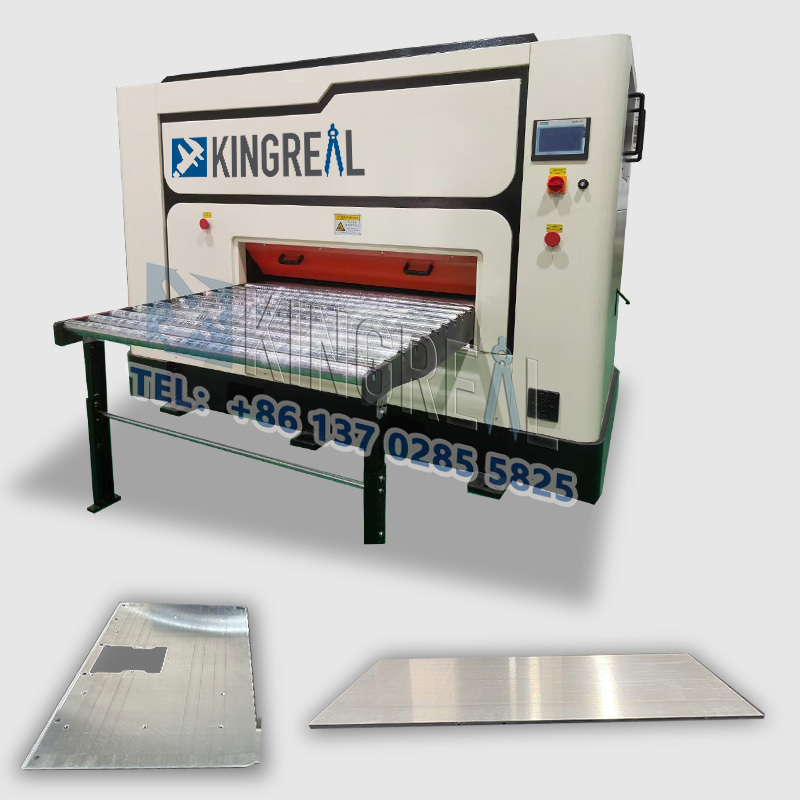

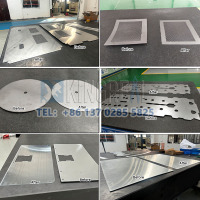

The sheet metal straightening machine's inlet and outlet can be equipped with optional motorized roller conveyors or PVC conveyor belts. For leveling light metal parts, KINGREAL CEILING MACHINERY recommends PVC conveyor belts; for heavy and large metal parts, steel roller conveyor belts are recommended. Steel roller conveyor belts efficiently transport metal parts from the inlet to the leveler and deliver the finished product at the outlet.

Conveyor Belt Specifications: Electric Roller Conveyor Belt Dimensions (W×L×H): Approximately 1900×1650×800mm per set (or as per design). Main Components: Steel roller conveyor rollers, steel support base, main motor with reducer, drive chain, etc. Main Motor: AC 2.2kW (or as per design). Conveyor Speed: 1-15 m/min (adjustable, equipped with a speed regulator). |  |

Parameter of Metal Plate Straightening Machine

| Machine Model | Model 1 | Model 2 | Model 3 | Model 4 | Model 5 | Model 6 | Model 7 |

| Roller Diameter | φ20mm | φ20mm | φ20mm | φ30mm | φ30mm | φ30mm | φ30mm |

| Roller Number | 21/23 | 21/23 | 21/23 | 21/23 | 21/23 | 21/23 | 21/23 |

| Leveled Width | 400mm | 600mm | 800mm | 400mm | 600mm | 800mm | 1000mm |

| Rated Plate Thickness | 0.3~1.2mm | 0.3~1.2mm | 0.3~1.2mm | 0.5~2mm | 0.5~2mm | 0.5~2mm | 0.5~2mm |

| Maximum Thickness | 2.0mm | 2.0mm | 2.0mm | 3.0mm | 3.0mm | 3.0mm | 3.0mm |

| Shortest Workpiece | 40mm | 40mm | 40mm | 60mm | 60mm | 60mm | 60mm |

| Applicable Object | Tape Coiling. Strip Steel, Sheet Metals,etc. | ||||||

Features of Metal Plate Straightening Machine

1) Multiple leveling roller sets for sheet metal straightening machine: The metal plate straightening machine consists of multiple leveling rollers, with upper and lower rollers working in concert. In addition, both upper and lower leveling rollers are equipped with support rollers to ensure balanced load distribution, prevent bending, and provide sufficient rigidity for the entire sheet metal straightening machine, making it particularly suitable for leveling thick plates and high-strength materials.

2) High-strength material for metal plate straightening machine: All leveling rollers and support rollers are made of GCr15 and undergo quenching and tempering, precision machining, hard chrome plating, and grinding to a surface hardness of HRC60±2° (chrome layer thickness ≥ 0.1mm). All gears are made of 20CrMnTi and undergo forging, quenching and tempering, surface carburizing, and precision grinding to IT6 grade.

3) High-efficiency main bearings for sheet metal straightening machine: The main bearings utilize Japanese NSK shielded and sealed bearings with self-lubricating oil, effectively preventing dust intrusion and eliminating the need for additional lubrication, reducing maintenance costs.

4) Electric adjustment system for metal plate straightening machine: A servo motor drives the leveling roller gap adjustment. Parameters can be set via the human-machine interface with an accuracy of 0.01mm, allowing for convenient adjustment of leveling performance.

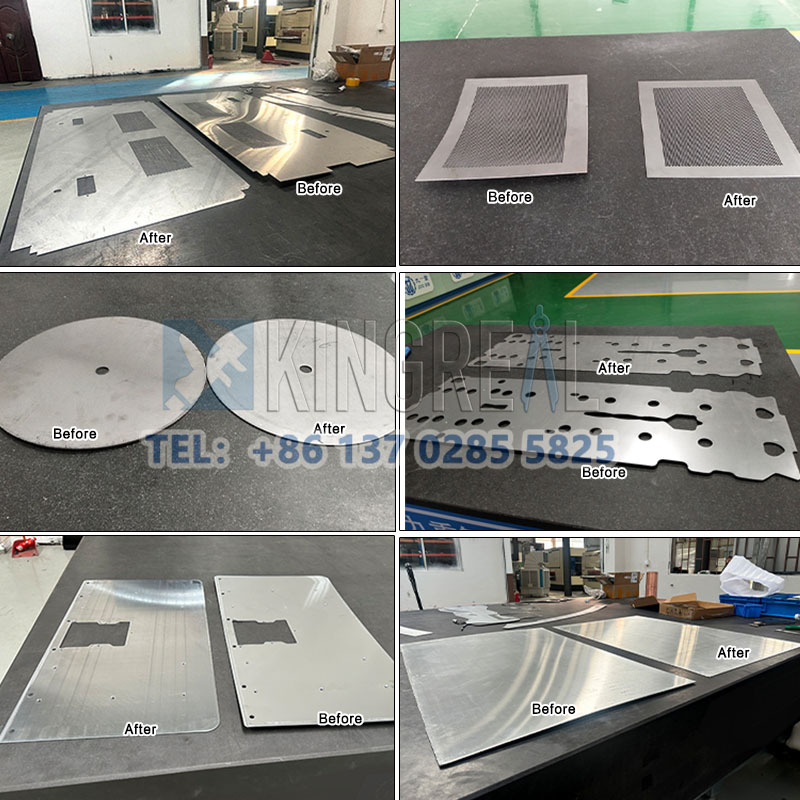

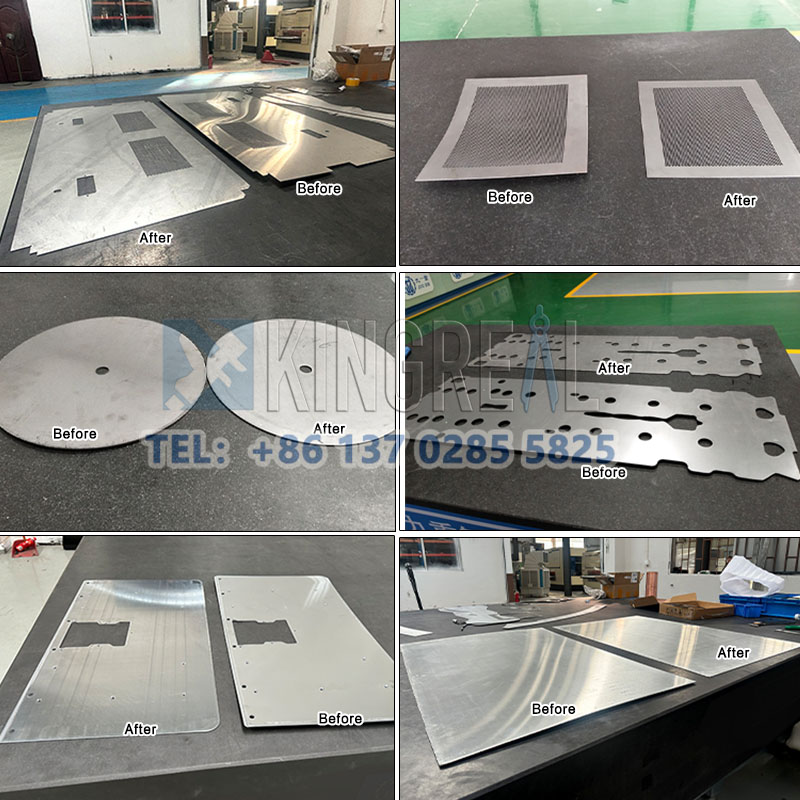

5) Micron-level flatness: By balancing internal stresses, the sheet metal straightening machine restores and improves the flatness of metal sheets to micron-level flatness, ensuring qualified workpieces for subsequent bending, welding, and other processes.

Advantages of Metal Plate Straightening Machine

1) Intelligent operation interface for metal plate straightening machine

KINGREAL CEILING MACHINERY sheet metal straightening machine’s main interface supports switching between Chinese and English, and can even be selected in the buyer's local language, ensuring easy user understanding and operation. Furthermore, the sheet metal straightening machine features the ability to save and retrieve key production parameters, such as leveling gap settings and material numbers. Once this data is saved on the human-machine interface, users can access it at any time without re-entering the data, improving operational convenience and efficiency. The sheet metal straightening machine can store up to 100 sets of data and can be customized to meet specific needs, making it easier to adjust leveling accuracy during repetitive production.

2) Overload protection for sheet metal straightening machine

The metal plate straightening machine is equipped with an overload protection function to ensure safe operation. Once the system detects an overload, it immediately issues an alarm and automatically shuts down the sheet metal straightening machine, effectively protecting all components of the sheet metal straightening machine and preventing damage caused by overload. This design not only reduces maintenance costs but also extends the life of the metal plate straightening machine, providing customers with enhanced safety.

3) High-strength leveling and support rollers for metal plate straightening machine

The leveling rollers in the sheet metal straightening machine are made of high-quality GCr15 material and undergo multiple processes, including tempering, precision machining, hard chrome plating, and grinding, achieving a surface hardness of HRC 58-62°. This ensures wear resistance and stability under high-intensity operating conditions. The support rollers are made of 40Cr and similarly undergo rigorous processing, achieving a surface hardness of HRC 48-53°. They are equipped with heavy-duty rolling bearings. This high-strength material and process ensure the reliability of the sheet metal straightening machine under high-load operation and can effectively support metal materials of various thicknesses and strengths.

4) Efficient power transmission for sheet metal straightening machine

The metal plate straightening machine utilizes a fully leveling roller drive system. The ends of each leveling roller are connected to a gearbox via a universal joint shaft. The gearbox is driven by a three-phase AC motor and a reducer. This drive system offers multiple advantages: high transmission strength, high torque, smooth operation, virtually silent operation, easy maintenance, and a long service life. All gears are made of 20CrMnTi and undergo processes including precision forging, tempering, surface carburizing, and precision grinding to achieve IT6 grade, ensuring the leveler maintains excellent performance even under long-term, high-load operation.

5) Micron-level flatness for sheet metal straightening machine

KINGREAL CEILING MACHINERY sheet metal straightening machines significantly restore and improve the flatness of metal sheets by balancing internal stresses, achieving micron-level flatness after leveling. This feature not only improves the quality of subsequent processes (such as bending and welding), but also ensures the precision and consistency of the final product, providing a solid guarantee for customers' production.

Various Types of Metal Plate Straightening Machines

KINGREAL CEILING MACHINERY offers both hydraulic and mechanical metal plate straightening machines to meet customers' diverse application and metalworking needs. The following is a brief introduction to these two types of sheet metal straightening machines:

Hydraulic precision metal plate straightening machine

Hydraulic sheet metal straightening machines utilize a hydraulic system to drive multiple leveling rollers up and down, repeatedly bending the metal sheet to achieve the desired leveling effect. This metal plate straightening machine uses a hydraulic cylinder and pump as its primary power source, providing powerful pressure and precise control, making it suitable for customers with stringent straightness requirements. The high pressure provided by the hydraulic system allows this machine to handle thicker and harder metal sheets.

Mechanical sheet metal straightening machine

A mechanical metal plate straightening machine uses a mechanical transmission system to drive the leveling rollers to level the metal sheet. This sheet metal straightening machine utilizes a motor, gears, connecting rods, and other mechanical components as a powertrain to achieve point-by-point leveling of the sheet. Mechanical metal plate straightening machines offer low manufacturing and maintenance costs, and their mechanical systems are relatively simple to maintain, eliminating the need for frequent component replacement.

FAQ About Metal Plate Straightening Machine

1.What is metal plate leveler?

2.What can a metal sheet straightening machine do?

3.Why do we need a sheet straightening machine?

4.What's working principle of sheet metal flattening machine?

5.What are the advantages of a sheet metal leveling machine?

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)