How to ensure quality of sheet metal perforation machine?

2025-09-04 17:00

Sheet metal perforation machine is also called metal perforated making machine or steel perforated machine.The quality of sheet metal perforation machines straight affects the accuracy of sheet metal perforations. of pierced sheets, which in turn impacts a business's brand reputation, market competitiveness, and customer satisfaction. For manufacturers, then, one of the most important issues is making sure the metal sheet perforated machine is good quality. Usually in machine building, several techniques are employed to manage sheet metal perforation machine quality, spanning from raw material procurement to last product delivery. Through regular quality management and control, these various quality control techniques can successfully avoid problems with quality and increase product consistency and dependability.

In this article, KINGREAL CEILING MACHINERY will discuss in detail the commonly used quality control methods in metal sheet perforated machine manufacturing and analyze how these methods can ensure product quality, help companies improve production efficiency, reduce waste, lower costs, and thus enhance market competitiveness.

1. Basic Concepts and Objectives of Sheet Metal Perforation Machine Quality Control

In metal sheet perforated machine manufacturing, quality control refers to the process of monitoring and adjusting each step of the production process to ensure that the perforated sheets meets established quality standards and customer requirements. The basic objectives of quality control are:

1.1 Ensure that the metal sheet perforated machine meets technical specifications and design requirements.

1.2 Prevent substandard products from entering the market and prevent quality incidents.

1.3 Improve production efficiency and reduce production costs.

1.4 Enhance the market competitiveness of sheet metal perforation machines and strengthen customer trust.

To achieve these goals, KINGREAL CEILING MACHINERY typically employs various quality control methods to ensure that high quality standards are met at every stage, from raw material procurement to metal sheet perforated machine production.

2. Classification of Sheet Metal Perforation Machine Quality Control Methods

When manufacturing metal sheet perforated machines, quality control methods can be categorized from multiple perspectives. They are primarily divided into the following categories:

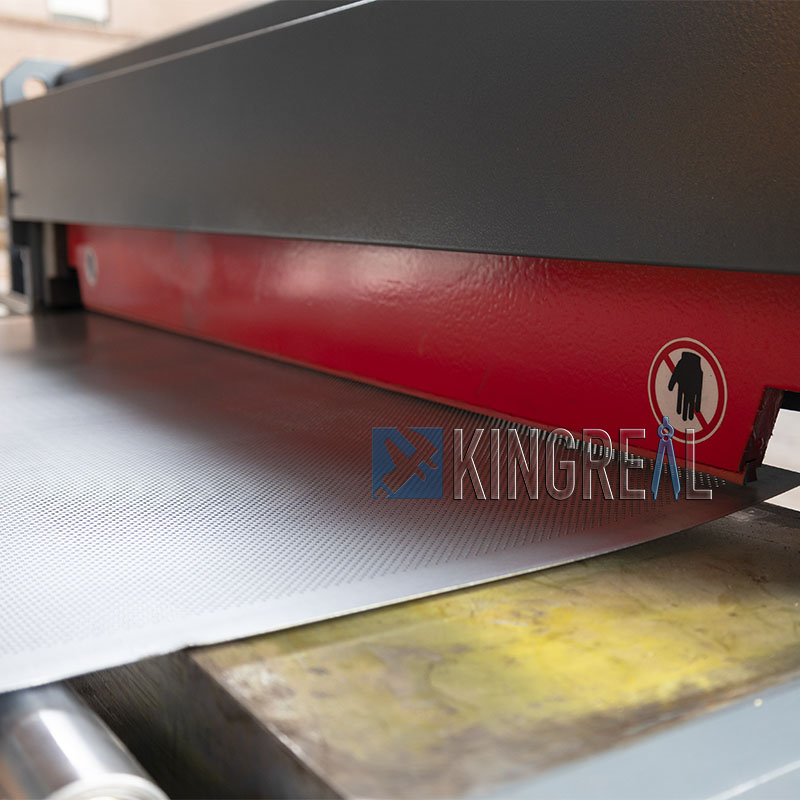

2.1 Process control for sheet metal perforation machine

Process control is the core of quality control and involves every aspect of the production process, including equipment operation, operator procedures, and the production environment. Through strict process control, each production step can be ensured to meet standards, thereby guaranteeing the quality of the perforated sheets. Common process control methods include:

– Statistical Process Control: By monitoring and statistically analyzing key indicators in the production process, potential quality issues can be promptly identified and adjusted.

– Automated Control: Utilizing advanced automated metal sheet perforated machine to monitor and adjust the production process in real time, reducing human error and improving production efficiency and stability.

– Standard Operating Procedures: Develop and implement detailed standard operating procedures to ensure that every step of the production process meets quality requirements.

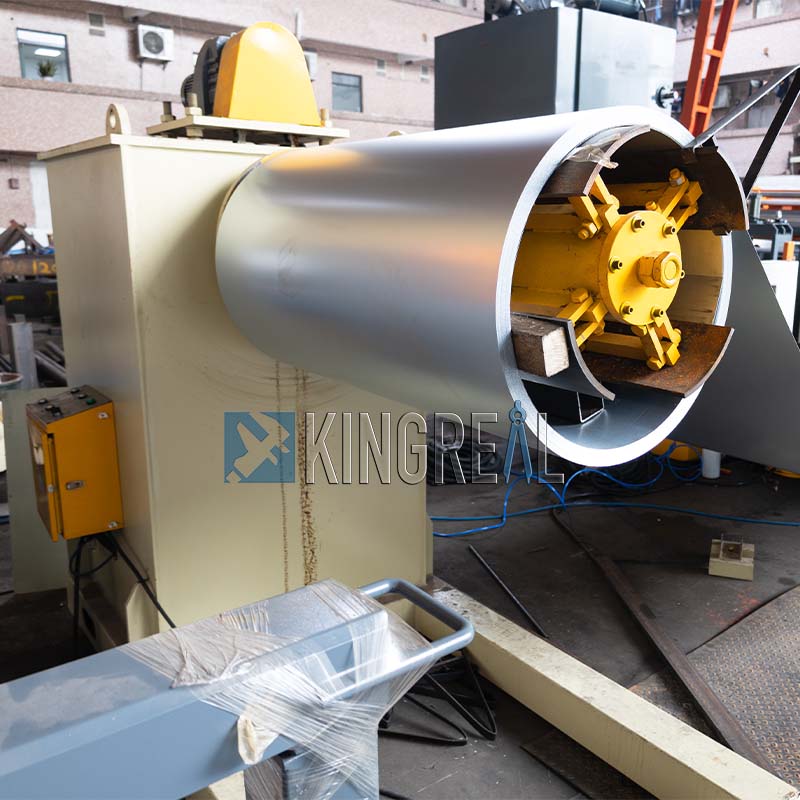

2.2 Material control for sheet metal perforation machine

Raw materials are the foundation of high-quality sheet metal perforation machines. Material selection, procurement, inspection, and use directly impact the quality of the final metal sheet perforated machine. Therefore, material control is a crucial step in quality control. Common material control methods include:

– Incoming Inspection: Stringently inspect the specifications and properties of raw materials to ensure they meet design requirements.

– Supplier Management: Build a stable and reliable supplier network and work with suppliers to develop quality standards to ensure material stability and consistency.

– Material Tracking: Record and trace each batch of materials to ensure that problems can be quickly identified when they occur.

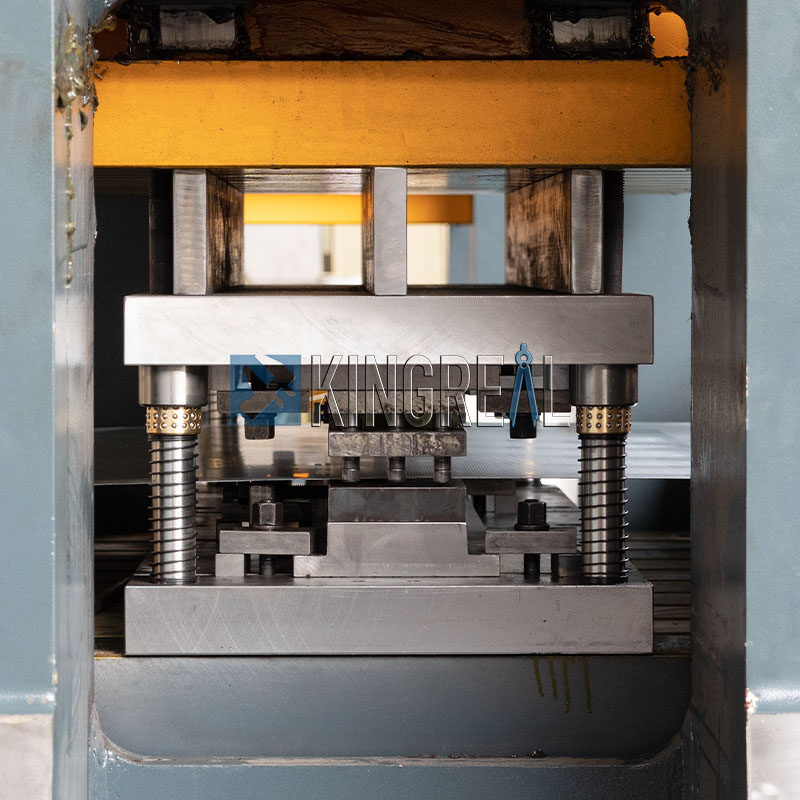

2.3 Production equipment management and maintenance

The precision and stability of production equipment play a decisive role in the quality of sheet metal perforation machine manufacturing. Effective equipment management and maintenance can minimize the impact of equipment failures on metal sheet perforated machine quality. Equipment management methods primarily include:

– Preventive Maintenance: Regularly inspect and maintain production equipment to ensure it is always in good working condition.

– Equipment Calibration: Regularly calibrate the equipment to ensure that its operating accuracy meets standards.

– Fault Analysis and Troubleshooting: Establish a mechanism for analyzing and troubleshooting equipment failures to promptly identify and resolve operational issues.

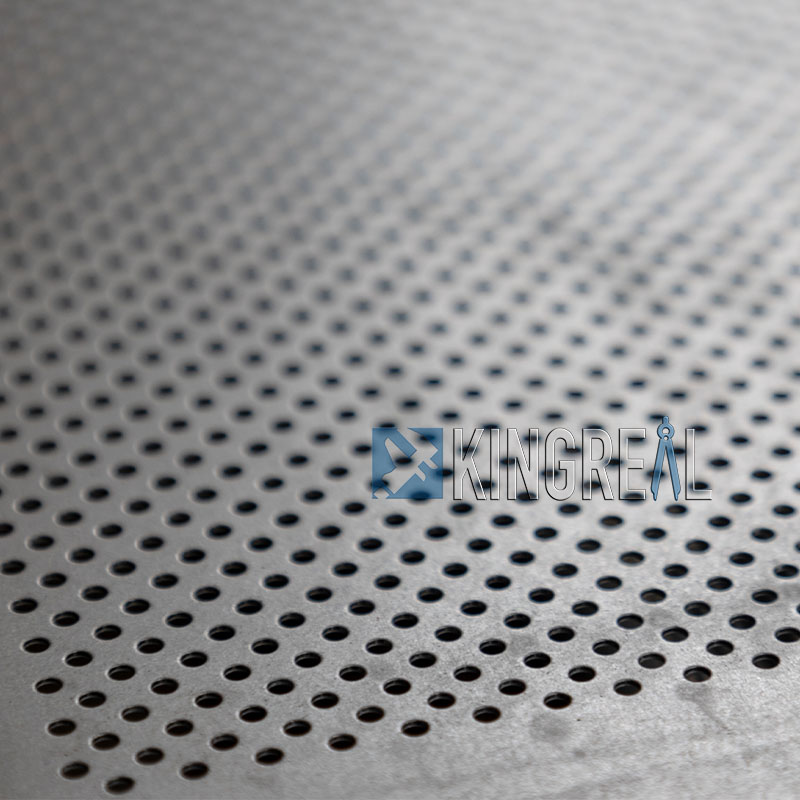

2.4 Inspection and testing for sheet metal perforation machine

Inspection and testing are key steps in metal sheet perforated machine quality control. Through rigorous inspection and testing, quality issues during the production process can be promptly identified and substandard products prevented from entering the market. Common inspection and testing methods include:

– Dimensional Inspection: Use precision instruments to inspect the dimensions of the sheet metal perforation machine to ensure compliance with design requirements.

– Performance Testing: Load a metal coil, start the metal sheet perforated machine, and perform performance tests under actual operating conditions to verify reliability.

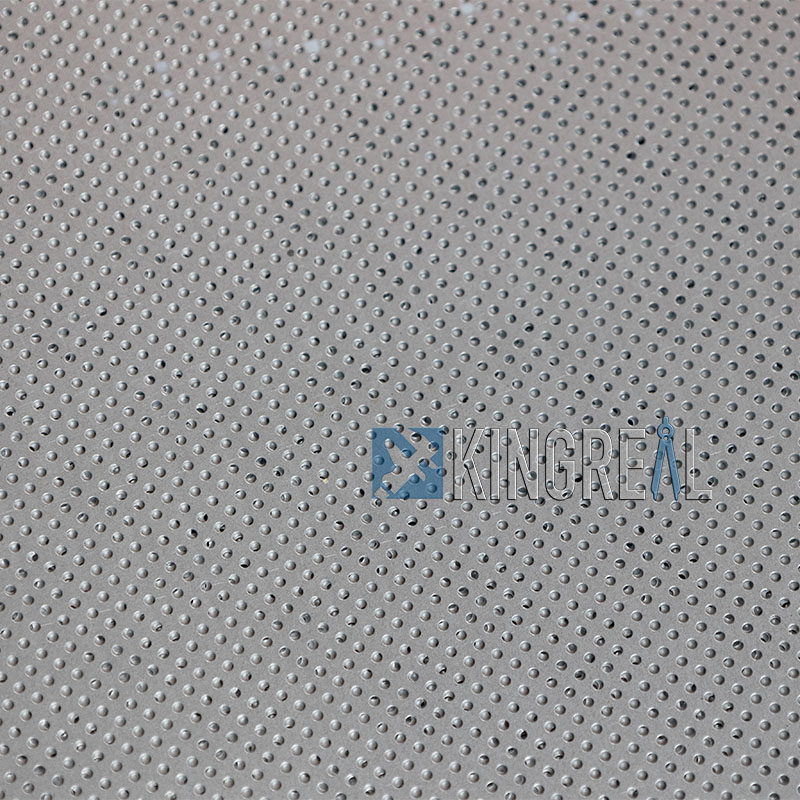

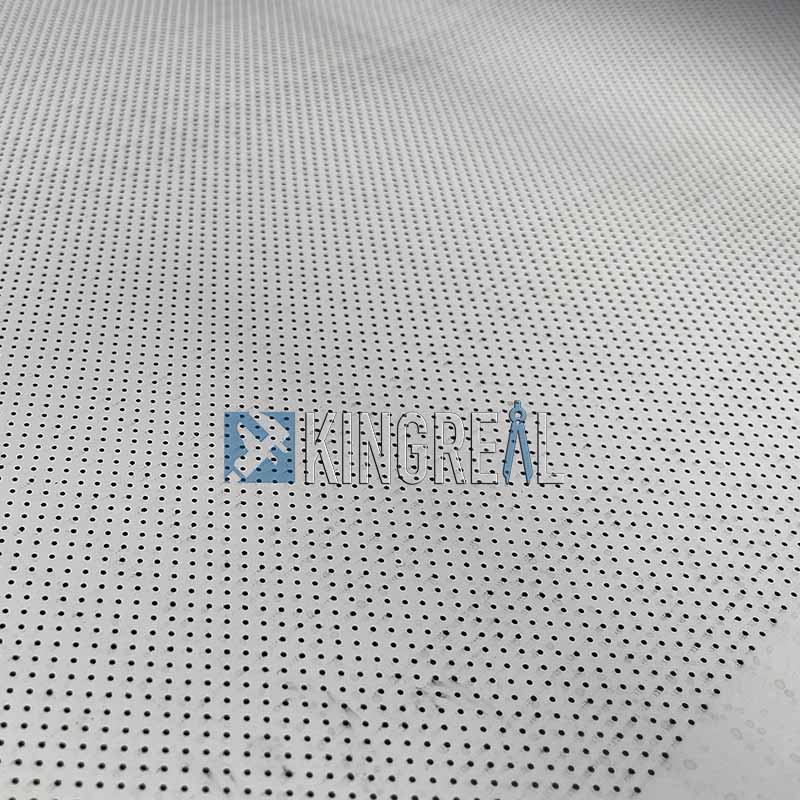

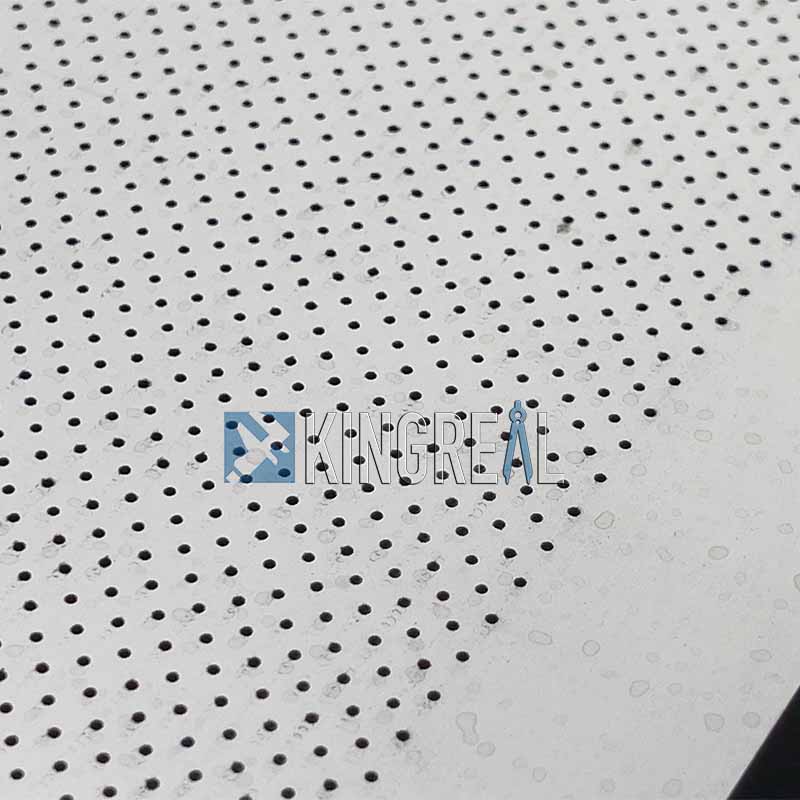

– Perforated Sheets Inspection: Measure the hole diameter of the perforated sheets and inspect the surface of the perforated sheet for burrs, etc.

3. Implementation Steps for Sheet Metal Perforation Machine Quality Control

To ensure metal sheet perforated machine quality, manufacturers must implement quality control at every stage of production. Specific steps include:

3.1 Quality control during the design phase

The design phase is the starting point of quality control, and design quality directly impacts the quality of subsequent production. During the design phase, manufacturers need to:

– Ensure that design drawings and technical requirements are clear and reasonable.

– Conduct design reviews to assess the design's manufacturability and testability.

– Select appropriate materials and processes to ensure design feasibility.

3.2 Quality control during sheet metal perforation machine production

During the production process, quality control focuses on ensuring that each step is performed according to standards to avoid quality fluctuations. Quality control during metal sheet perforated machine production should include:

– Strictly adhere to operating standards to ensure that operators follow specifications.

– Implement real-time monitoring during the production process to promptly identify problems and make adjustments.

– Conduct statistical analysis of process data to ensure the stability of the production process.

3.3 Final inspection and shipment quality control

After the sheet metal perforation machine is completed, final inspection is the last line of defense to ensure product quality. At this stage, manufacturers need to:

– Conduct a comprehensive inspection of the metal sheet perforated machine to ensure that it meets design and technical standards.

– Isolate unqualified machines and promptly return them for repair or scrapping.

– Record quality inspection results to ensure traceability.

If you want to know more information about metal sheet perforated machine, please contact KINGREAL CEILING MACHINERY!

Get the latest price? We'll respond as soon as possible(within 12 hours)