What is Metal Ceiling Channel Machine?

2025-06-21 17:00

Video About Metal Ceiling Channel Machine

Description of Metal Ceiling Channel Machine

Metal ceiling channel machine is a special equipment for producing metal ceiling channels through cold rolling forming process. It is mainly used for the manufacture of non-load-bearing partition wall systems and ceiling keel frames in the construction field. It can produce profiles of various shapes such as U channel, hat channel, wall angle, etc. The false ceiling channel machine uses strip steel as raw material, forms false ceiling channels with complex cross-sections such as U-shaped, L-shaped, and hat-shaped through continuous cold rolling, and is widely used in the production of metal ceiling channels. The metal ceiling channel machine adopts PLC control system, has the characteristics of high efficiency and high degree of automation, and its production speed can reach 120 m/min. KINGREAL CEILING MACHINERY Roll forming machines for ▷ Metal Ceiling Channel Machine | Furring Channel | U Channel | Wall Angle ◁ produce Impeccable profiles and connectors. There are a variety of false ceiling channel types that can be produced by KINGREAL CEILING MACHINERY false ceiling channel machine: |  |

Features of Metal Ceiling Channel Machine Components

| ①Double-head decoiler for false ceiling channel machine. KINGREAL CEILING MACHINERY can equip the false ceiling channel machine with a double-head decoiler. By setting two unwinding, unwinding and shrinking coil barrels on the rotating shaft of the integral frame, the material roll can be installed on the other unwinding, unwinding and shrinking device while feeding the material in one unwinding, unwinding and shrinking device, without interrupting the processing and production. It is currently the most efficient and stable unwinding equipment. KINGREAL CEILING MACHINERY equips the metal ceiling channel machine with a double-head decoiler to improve production efficiency for customers and reduce the waste of material change time caused by the exhaustion of coils. |  |

| ②Protective shield for false ceiling channel machine. In order to maximize the production safety of workers and comply with the regulations of some countries on machine protection equipment, KINGREAL CEILING MACHINERY has designed a protective shield for the customer's metal ceiling channel machine. When the false ceiling channel machine is running, the protective shield can cover the roll forming machine to prevent workers from being injured by accidental contact with the running parts. When shutting down the metal ceiling channel machine or performing daily maintenance, the protective shield can be easily opened. |  |

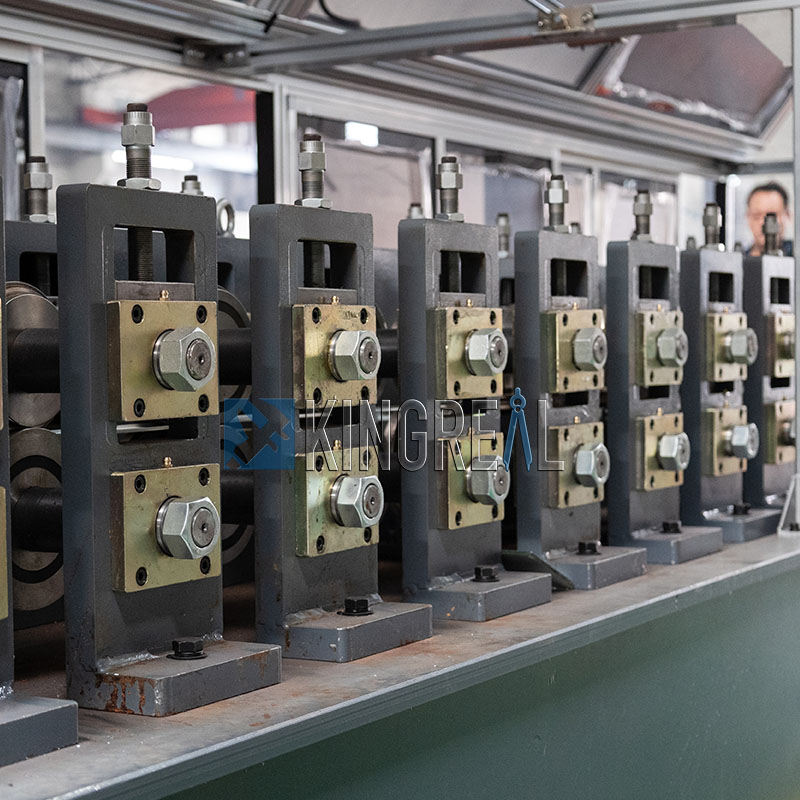

| ③Independent archway for false ceiling channel machine. KINGREAL CEILING MACHINERY has equipped the roll forming machine with an independent archway. The archway frame consists of two side columns, which are fixed to the side wall of the table by fasteners. Cylindrical positioning pins and quick-change latches are set between the column and the table to ensure that one side is positioned and the other side can be quickly disassembled. This design allows the arch frame of the roll forming machine to quickly replace the rollers. The long columns at the four corners of the table provide support. There are round holes at the lower end of the long columns. The screws on the upper part of the arch frame can be used for positioning to achieve the overall hoisting of the spare table and reduce the floor space. |  |

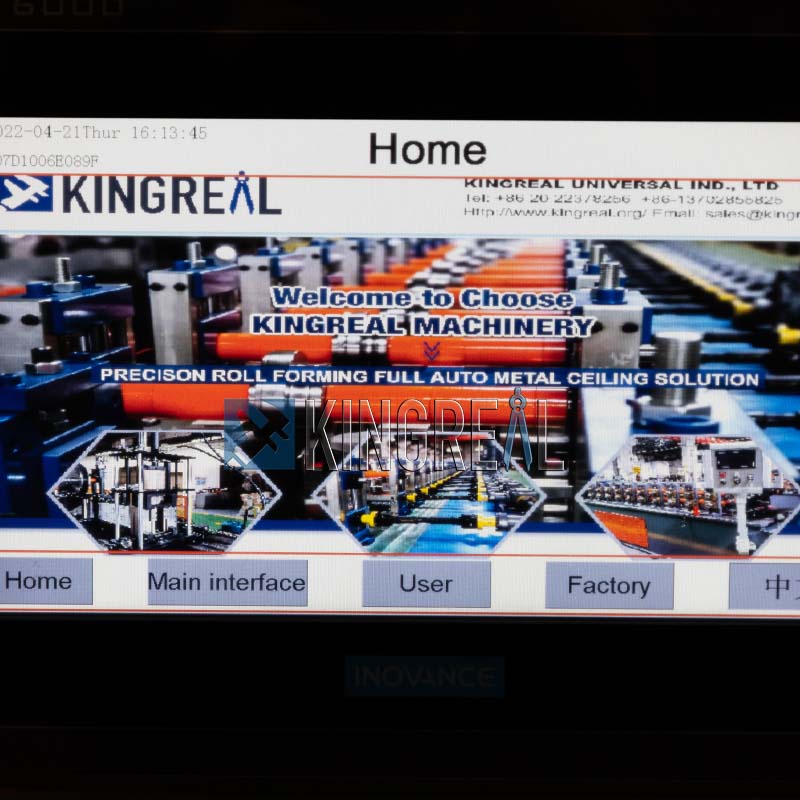

| ④ Friendly smart screen for metal ceiling channel machine. KINGREAL CEILING MACHINERY has equipped each false ceiling channel machine with an advanced smart control panel to enhance the user experience. The panel supports language selection according to the customer's region, making operation more convenient. Customers can easily set parameters such as machine speed, production output, and finished product length to achieve personalized production. |  |

Various Metal Ceiling Channel Machines

KINGREAL CEILING MACHINERY can provide personalized manufacturing solutions for false ceiling channel machines based on customer drawings and combined with actual production conditions, which can be divided into:

| |

| |

③Gypsum wall angle making machine. |  |

④ 3-in-1 metal ceiling channel machine. |  |

Application of Metal Ceiling Channel Machine

False ceiling channel machine is widely used in various construction projects, especially in modern architectural design, playing a vital role. This false ceiling channel machine is usually used in conjunction with u channel machines, furring channel machines and wall angle machines to form an efficient support system. They not only provide structural support, but also ensure the stability of ceilings and walls.

In the construction of commercial buildings, residential and industrial facilities, these metal ceiling channel machines can quickly and efficiently produce the required profiles to meet different design and functional requirements. By combining different types of false ceiling channel machines, construction teams can flexibly respond to various construction challenges and ensure construction quality and safety. In addition, the application of this system also makes later maintenance more convenient and improves the overall service life of the building. |  |

Why Choose KINGREAL CEILING MACHINERY?

tags: Metal Ceiling Channel Machine, False Ceiling Channel Machine, Hat Channel Machine, Omega Channel Machine, Furring Channel Machine, U Channel Machine, Main Channel Making Machine, Gypsum Wall Angle Making Machine, Gypsum Ceiling Channel Making Machine, Drywall Wall Angle Profile Machine, L-Shaped Profile Making Machine, Gypsum Board Wall Angle Machine

Get the latest price? We'll respond as soon as possible(within 12 hours)