What are the different types of perforated metal machines?

2025-06-17 17:00

Perforated metal coils are made on a perforated metal machine, where they are continuously fed and perforated. Perforated metal materials are widely used in a variety of fields, including construction, automobiles, home appliances, and filtration systems, so understanding the different types of metal perforated making machines is essential to choosing the right equipment.

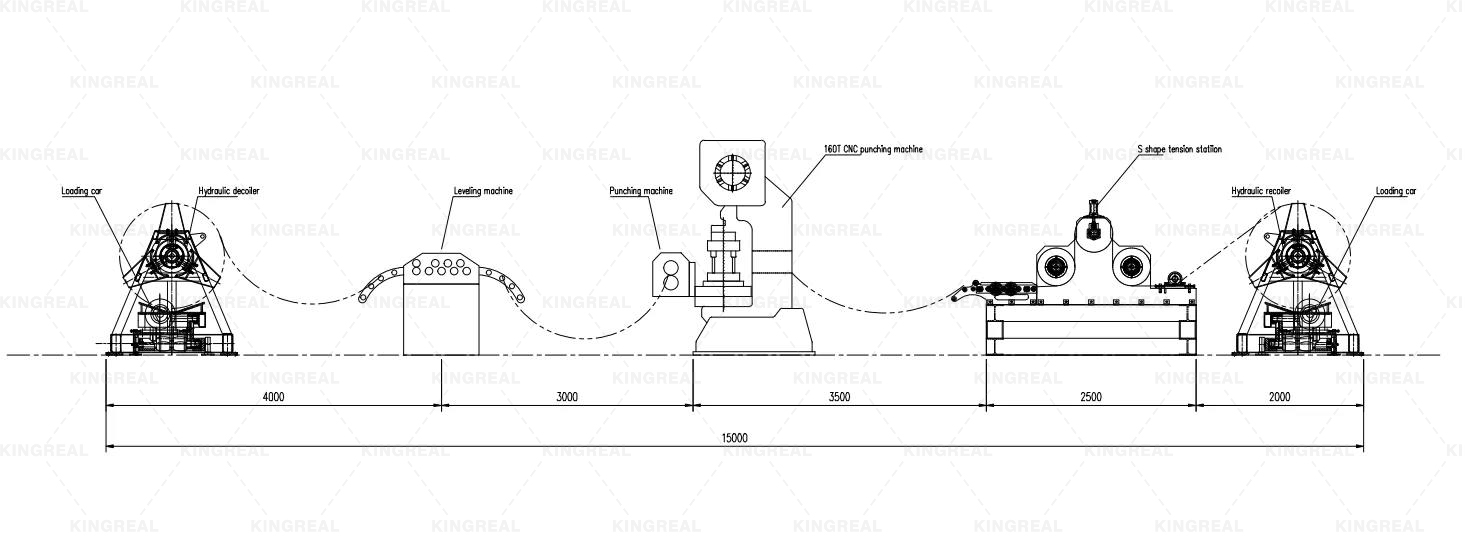

Composition of Perforated Metal Machines

Metal perforated making machines mainly consist of the following parts:

Decoiler for perforated metal machine : Decoiler is responsible for feeding ordinary coils into the feed rollers of the machine. Its function is to unwind the coils for the subsequent punching process.

Precision Straightener for perforated metal machine: Straightener is an independent component, which is mainly used to straighten the coils before entering the punching machine to eliminate the warping and bending of the material to ensure the quality of the subsequent punching.

Punching machine for perforated metal machine: The punching machine is the core part of the metal perforated making machine and is responsible for punching the predetermined holes on the coil. The shape, size, and spacing of the punching holes can be customized according to customer needs.

Cutting station for perforated metal machine: When the metal perforated making machine completes the perforation, the cutting station will cut the perforated coil into the required plates according to the set length.

Recoiler for perforated metal machine: For applications that require full roll perforation, the perforated coil enters the winding stage directly after punching, without cutting, to form a full roll of perforated material.

These components work together to successfully produce perforated coils or plates that meet customer needs.

Introduction to Coil to Coil Perforation Line and Perforated Metal Machine

High efficiency: Due to the use of a systematic production process, the coil to coil perforation line can complete a large number of punching and winding work in a short time, significantly improving production efficiency.

Cost advantage: Mass production significantly reduces the cost of raw materials. By optimizing the production process, enterprises can save manpower and material resources and improve overall efficiency. Customization capability: Manufacturers can customize molds with different hole types according to customer drawings and needs to ensure the production of high-quality perforated coils that meet market demand. Coil to coil perforation lines are often used to produce a variety of products such as automotive mufflers, filters, drain pipes and air conditioning duct systems. These products have high requirements for combination and durability, and coil to coil perforation lines can meet these needs. |  |

Metal sheet perforated making machine

Flexibility: The metal sheet perforated making machine can adjust the length of the perforated sheet according to the needs of different products, suitable for a variety of production modes. Wide application: The metal sheet perforated making machine is suitable for making a variety of products such as rolling shutters, ventilation and heat dissipation panels, screens, baskets, stairs, chairs, wall panels and bread trays. These products usually require specific shapes and sizes, and the metal perforated making machine can flexibly respond to different customer needs. High precision: Since the metal sheet perforated making machine can accurately cut each sheet, the quality and consistency of the finished product are ensured. When choosing to use a coil to coil perforation line or a metal sheet perforated making machine, the company needs to make a reasonable judgment based on the production process and market demand of the required finished product. |  |

Application Areas of Perforated Metal Machine

Perforated metal materials are widely used in many fields. In the automotive industry, coil to coil perforation lines are used to manufacture silencers and other components, which require materials with good air permeability and strength. In the construction industry, perforated metal machines are used to produce a variety of decorative and functional metal sheets, such as ventilation and heat dissipation panels and screens.

In addition, perforated metal materials also play an important role in filtration systems. Coil to coil perforation lines can produce high-efficiency filters suitable for fields such as water treatment and air purification. Due to its efficient production line, the processing process of perforated coils is more streamlined and efficient, thus shortening production time and saving costs. |  |

Features of Perforated Metal Machine

1

Efficient production

Metal perforated making machines are designed to improve production efficiency.

Through systematic process flow, enterprises can complete large quantities of perforation work in a short time, reduce production cycle and improve market competitiveness.

2

Cost control

Mass production has significantly reduced the cost of raw materials per unit product.

For manufacturers, optimizing production processes can not only improve resource utilization efficiency, but also effectively control production costs.

3

Customized service

With the diversification of market demand, the customization ability of perforated metal machines has become increasingly important.

Manufacturers can provide personalized solutions according to the specific needs of customers to ensure that products that meet customer requirements are produced.

4

Quality assurance

Metal perforated making machines are usually equipped with high-precision equipment to ensure that the perforated products produced meet standards in terms of hole shape, size and overall quality.

This is essential to maintaining customers' brand image and market reputation.

Get the latest price? We'll respond as soon as possible(within 12 hours)