Why are metal ceiling machines so popular?

2025-06-15 17:00

Metal ceiling machine is to produce ceiling tiles of different sizes and types, such as 300x300mm, 600x600mm, 600x1200mm, etc., by passing galvanized iron coils, aluminum coils, roll-coated coils and other metal materials through Hydraulic Decoiler, Precision Straightener, Perforation Press, Servo feeding machine, Notching and shearing press, 2nd Precision straightener, Tiles flipping machine, Automatic tiles feeding machine and other precision parts. The metal ceiling panels produced by KINGREAL CEILING MACHINERY are widely used in homes, schools, offices, subway stations, hotels and other places. They are warmly welcomed by the market because of their beautiful appearance, easy installation, easy disassembly and durability. In this article, KINGREAL CEILING MACHINERY will discuss with you the reasons why metal ceiling panel production lines are widely welcomed by markets around the world to help you better choose metal ceiling machines. KINGREAL CEILING MACHINERY is a metal ceiling panel production line manufacturer with more than 20 years of rich experience. If you are interested in metal ceiling machines and want to get more information, please consult KINGREAL CEILING MACHINERY! |  |

Main Reasons for the popularity of Metal Ceiling Machines

1. Market demand for diversified product Modern buildings have increasingly diversified requirements for ceiling materials. Architects and contractors hope to be able to choose the right ceiling materials and styles according to different indoor environments and customer needs. Based on this market demand, KINGREAL CEILING MACHINERY metal ceiling panel production lineprovides production capacity compatible with both aluminum and iron metal materials to meet the diverse needs of different customers. For example, KINGREAL CEILING MACHINERY metal ceiling machine can not only produce common types of metal ceiling panels such as clip in, lay in and tegular, but also produce metal ceiling tiles of various sizes such as 300x300mm, 600x600mm, 600x1200mm according to the specific requirements of customers. In addition, as consumers pursue personalized design, the decorativeness and functionality of metal ceiling tiles are becoming more and more important. The diverse options of KINGREAL CEILING MACHINERY metal ceiling panel production line allow customers to choose the right materials and designs according to the specific needs of the project, further enhancing market competitiveness. |  |

2. Ability for effective manufacture For companies, profitability and market response speed depend directly on manufacturing efficiency in contemporary times. Conventional metal ceiling machines can no longer satisfy this demand as client needs for metal ceiling tile production line efficiency slowly rise. Consequently, contemporary metal ceiling panel production lines have evolved and are now the main approach for raising output effectiveness. Modern metal ceiling panel production lines have more automated components than do conventional metal ceiling machines. For instance, KINGREAL CEILING MACHINERY metal ceiling machines can be fitted with feeding trolleys, acoustic fleece sticking machine, metal sheet cleaning machine, etc. These automatic systems may boost production speed and cut hand labor. Automated systems enable the metal ceiling machine to swiftly adapt to market need and guarantee on-time delivery. Using KINGREAL CEILING MACHINERY metal ceiling machines often allows consumers to dramatically increase their production efficiency, shorten project delivery cycles, and boost their market competitiveness, hence lowering labor expenses and raising general production efficiency so companies may hold a favorable position in the intense market rivalry. |  |

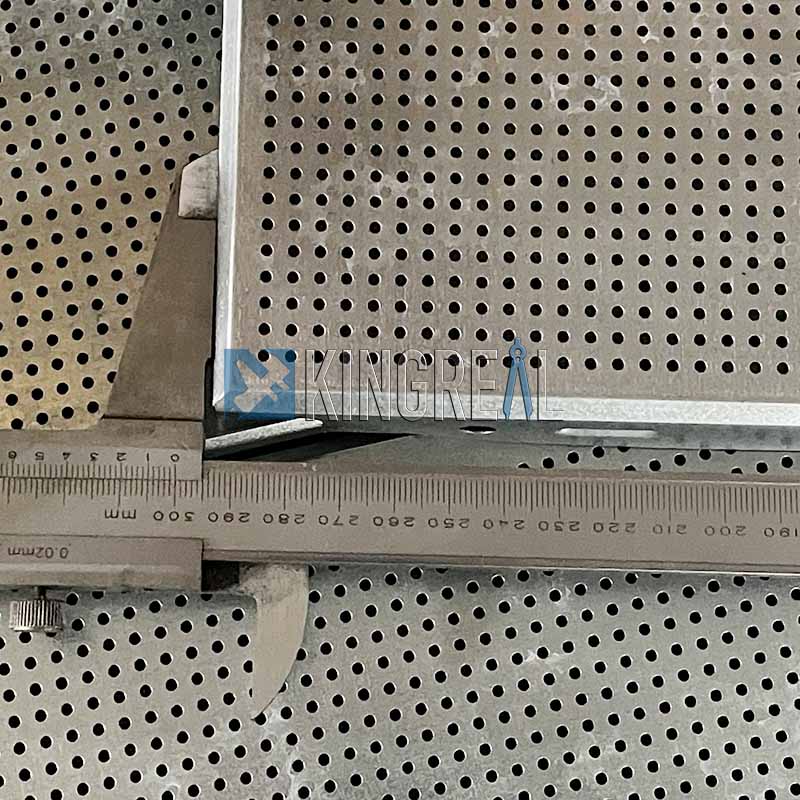

3. Exact product quality KINGREAL CEILING MACHINERY adheres to a thorough set of quality control procedures to guarantee that every piece may meet high standards and has quite rigorous manufacturing specifications for metal ceiling panel production lines. High precision manufacturing allows KINGREAL CEILING MACHINERY metal ceiling panel production line to satisfy the quality control and standardized production criteria. This helps consumers lower post-processing costs and waste rates as well as ensures dependability and uniformity of the products. By means of exact manufacturing techniques, consumers can get higher quality metal ceiling tiles and raise the market worth of the finished goods. Additionally offering complete after-sales service, KINGREAL CEILING MACHINERY guarantees that users have access to prompt technical assistance and maintenance during use. KINGREAL CEILING MACHINERY has gained recognition in the market as a result of its tight quality control and excellent customer service. |  |

4. Cost-effectiveness The high efficiency and precision of KINGREAL CEILING MACHINERY metal ceiling panel production line not only improve production efficiency, but also reduce production costs. This enables companies to obtain higher profit margins while maintaining product quality. By using modern metal ceiling machines, companies can reduce human resource input and reduce labor costs. At the same time, precise production processes reduce scrap rates and reduce the waste of raw materials, thereby further reducing production costs. In the long run, investing in KINGREAL CEILING MACHINERY metal ceiling panel production line will bring companies a considerable return on investment. Application of Metal Ceiling Machine KINGREAL CEILING MACHINERY metal ceiling panel production line can produce plain ceiling tile, perforated metal ceiling tile,etc. according to customers’ different production need. |  |

Get the latest price? We'll respond as soon as possible(within 12 hours)