What's the advantages of baffle ceiling machine?

2025-06-14 17:00

Introduction of Baffle Ceiling Machine

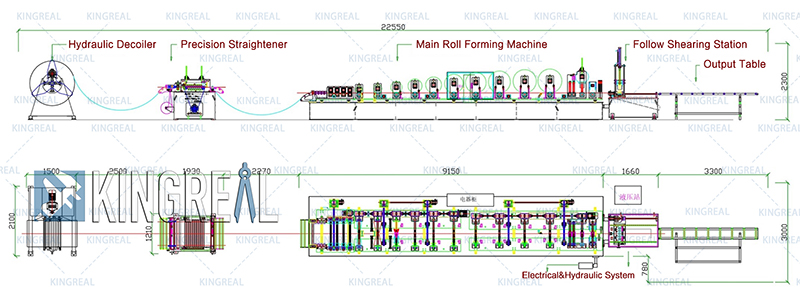

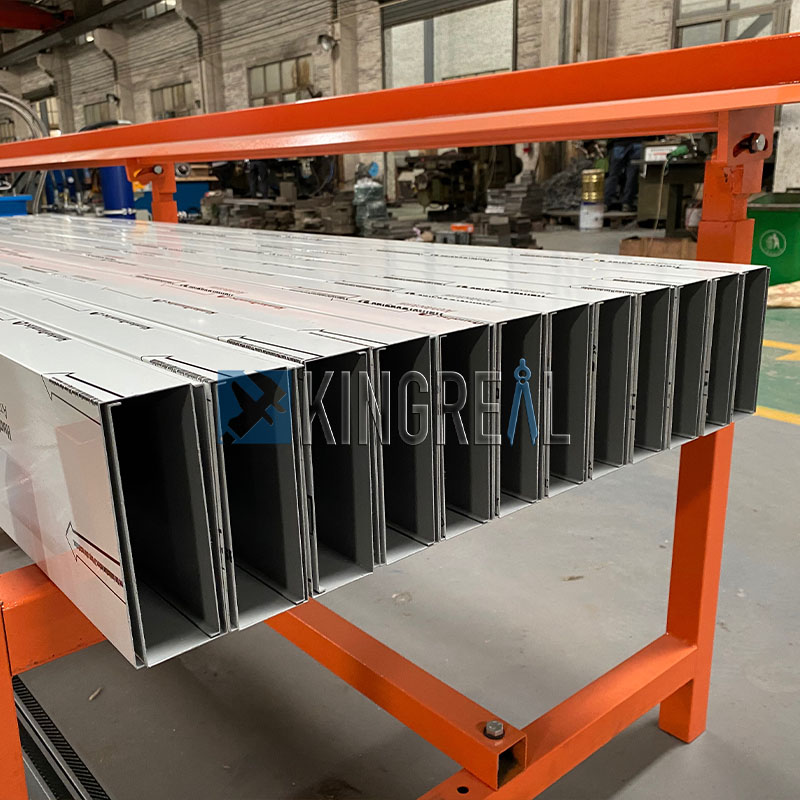

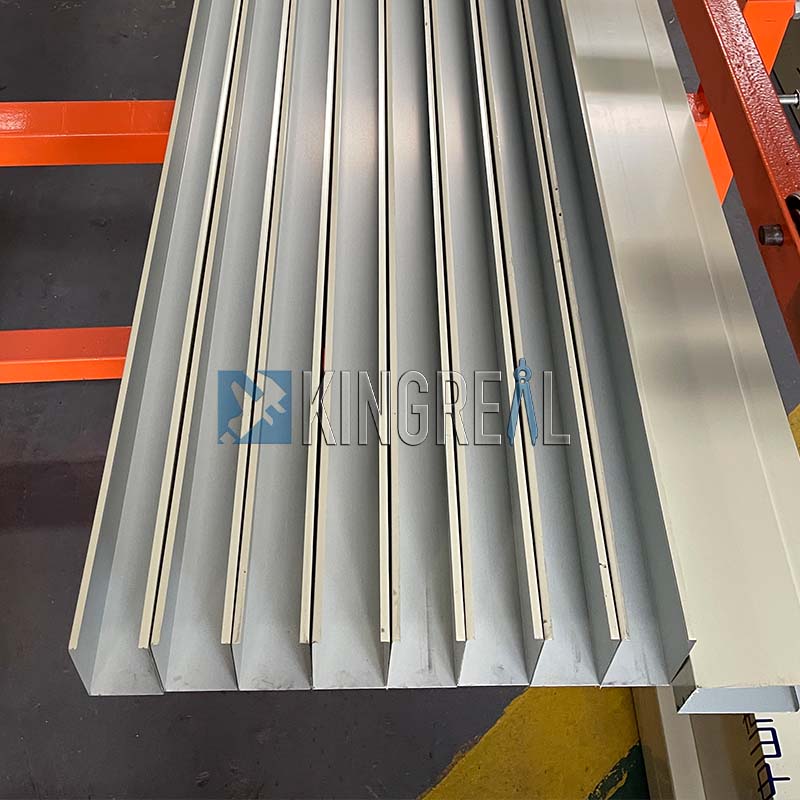

The baffle ceiling machine is to put metal materials such as galvanized sheet, aluminum sheet or roll-coated sheet into the machine and pass through the precision parts such as decoiler, precision straightener, main roll forming machine, cutting station to produce baffle ceilings of different sizes and types that meet customer needs, such as U-shaped baffle ceilings, V-shaped baffle ceilings, etc. The baffle ceiling making machine has the advantages of stable operation and precision production, and the maximum production speed can reach 30m/min. The baffle ceilings produced by KINGREAL CEILING MACHINERY baffle ceiling machines have become the main products that have swept the decoration market in recent years because of their open vision, ventilation, simple and clear modern style, simple and convenient installation and disassembly. |  |

Working Process of Baffle Ceiling Making Machine

Hydraulic Decoiler ↓ Precision Straightener ↓ Main Roll Forming Machine ↓ Product Table |  |

Advantages of Baffle Ceiling Machine

Customized baffle ceiling making machine. KINGREAL CEILING MACHINERY engineers will provide customized baffle ceiling machine manufacturing solutions based on the customer's drawings and combined with the customer's actual production needs (such as production scale, thickness of metal processing materials, etc.).

The following are KINGREAL CEILING MACHINERY featured baffle ceiling making machines. So far, these baffle ceiling machines have been shipped to customer factories in Brazil, Mexico, Turkey, Italy, Russia, the Netherlands and other countries.

(1) According to customers' different requirements for baffle ceiling sizes.

KINGREAL CEILING MACHINERY has designed three baffle ceiling making machines to effectively help customers meet different production needs, namely 150mm height baffle ceiling making machine, 200mm height baffle ceiling making machine and 300mm height baffle ceiling making machine. These three baffle ceiling machines have their own characteristics in the height and width of baffle ceilings, which can meet customers' needs for baffle ceilings of different sizes:

150mm height baffle ceiling machine: can produce baffle ceilings:height range of 35-150mm, the width range of 30-100mm

200mm height baffle ceiling machine: can produce baffle ceilings: height range of 35-200mm, the width range of 30-100mm

300mm height baffle ceiling machine: can produce baffle ceilings: height range of 35-300mm, the width range of 50-100mm

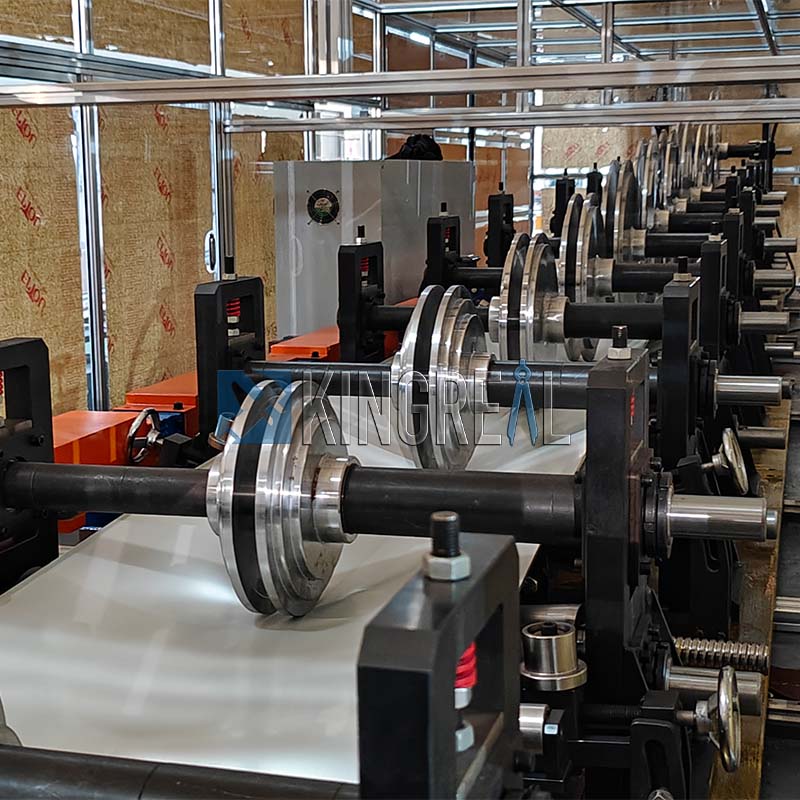

This flexible baffle ceiling making machine design enables customers to accurately meet market demand during production and avoid resource waste caused by parameter mismatch. It is worth mentioning that the 300 baffle ceiling machine is specially designed for Douglas, a customer with special size requirements. Its unique roll forming machine roller has been upgraded and adopts a hollow roller design to ensure that the quality of precision forming and rolling can be maintained under high-size production.

(2) Baffle ceiling making machine with high safety performance.

In modern manufacturing, safety is an important factor that cannot be ignored. KINGREAL CEILING MACHINERY is well aware of the importance of production safety. Therefore, in the design of the baffle ceiling machine, special attention is paid to improving safety performance. In order to meet customers' high requirements for production safety and the policy requirements of some countries for machine safety equipment, KINGREAL CEILING MACHINERY baffle ceiling making machine is equipped with a protective shield.

The protective shield will completely cover the roll forming machine when the baffle ceiling making machine is running, effectively preventing workers from being injured by accidentally touching machine parts during the production process. Through this design, KINGREAL CEILING MACHINERY not only improves the safety of the baffle ceiling machine, but also enhances the workers' work confidence, allowing them to focus more on production tasks without worrying about potential safety hazards.

In addition, other safety designs of the baffle ceiling making machine include emergency stop buttons, overload protection devices, etc., to ensure that the power supply can be quickly cut off in any abnormal situation to protect the safety of the equipment and operators.

(3) Fully automatic baffle ceiling machine.

In the modern production environment that pursues efficiency, automation has become an important means to improve productivity. In order to meet customers' needs for fully automatic production processes, KINGREAL CEILING MACHINERY equipped the baffle ceiling machine with a feeding trolley. This automated equipment can automatically transport large rolls of metal coils to the decoiler, greatly reducing the need for manual intervention.

The introduction of the feeding trolley makes the production process smoother, reduces labor costs, and improves production efficiency. In traditional manual operations, workers need to frequently carry out material handling and transportation, while the fully automatic feeding system can effectively liberate manpower, allowing workers to focus more on other more valuable work.

In addition, the fully automated production process can also be monitored and analyzed in real time through the intelligent management system, helping enterprises to adjust production parameters in time and optimize production efficiency. Such intelligent management not only improves production flexibility, but also enables problems in the production process to be quickly identified and solved, thereby reducing downtime and resource waste.

Product Display

KINGREAL CEILING MACHINERY baffle ceiling making machine, with its excellent manufacturing process and advanced technology, produces baffle ceilings that have reached the industry-leading level in terms of precision and quality.

The high precision of the baffle ceiling is due to the precision molding technology used by KINGREAL CEILING MACHINERY in the design and production process. Each baffle ceiling machine undergoes strict quality control to ensure that high standards are maintained in every link of the production process, so that the size of the baffle ceiling can fully meet customer needs.

Get the latest price? We'll respond as soon as possible(within 12 hours)