How many types of ceiling t grid machines?

2025-06-06 17:00

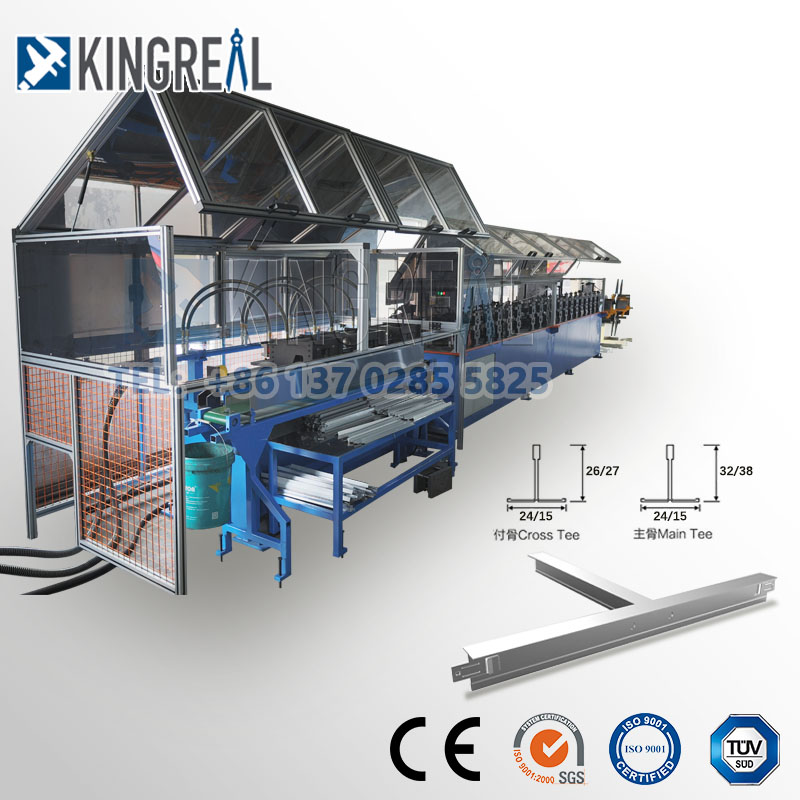

Ceiling t grid machine is also often called ceiling t bar machine. KINGREAL CEILING MACHINERY can provide a full range of ceiling t grid machines for the production of ceiling t bar (main t and cross t) supporting ceiling panels. KINGREAL CEILING MACHINERY ceiling t bar machines are available in various versions. Customers can choose the right ceiling t grid machine according to the type of profile, output and degree of automation they need.

Video About Ceiling T Grid Machine

Different Types of Ceiling T Grid Machine

KINGREAL CEILING MACHINERY launches different types of ceiling t bar machines according to customers' different needs for finished products:

By adjusting the roller group of the roll forming machine or changing the cutting die, a flat t grid machine can produce flat t bar of different sizes. |  |

This FUT ceiling t bar machine is a fully automatic ceiling t bar machine that can fully automatically form and punch and cut. The production speed can reach 25m/min. |  |

Black line ceiling t grid machine. The special thing about the black line ceiling t bar machine is that it will hang a bottle for the black line ceiling t grid machine, and the ink in the bottle will accelerate the drying of the ink to produce high-precision black line ceiling t grids. It is worth mentioning that the ink equipped by KINGREAL CEILING MACHINERY is quick-drying, so there is no need to dry the black line ceiling t grids later. |  |

Silhouette ceiling t bar machine. The maximum speed of this silhouette ceiling t grid machine can reach 30m/min. KINGREAL CEILING MACHINERY is equipped with a fully automatic roll forming machine and a punching machine for this silhouette ceiling t grid machine. |  |

Ceiling Grid Wall angle profile machine. The fully automatic ceiling grid wall angle profile machine can produce common finished product sizes such as 19x19mm, 24x24mm, 19x24mm. It can achieve a ceiling grid wall angle profile machine to produce finished products of different sizes. In order to meet the different needs of customers for production speed, this ceiling grid wall angle profile machine has three speed options: 30m/min, 50m/min and 70m/min. |  |

※Ceiling t bar machine with protective shield. In order to meet customers' high requirements for production safety, KINGREAL CEILING MACHINERY can equip various types of ceiling t grid machines with protective shields to improve the safety of ceiling t bar machines for customers. |  |

Parameters of Ceiling T Grid Machine

| Serial | Name | Material | Finish & Heat Treatment | Detail |

| 1 | Machine Body | 20mm carbon steel | Polished | |

| 2 | Side Plate | 30mm | Polished | |

| 3 | Principal Axis | 45# steel | Tempered | |

| 4 | Roller | Cr12 | HRC55-56 | 18pairs, symmetry allowance 0.05mm |

| 5 | Transmission | Chain/worm gearbox reduce | ||

| 6 | Stitch | Four Rollers real stitch can also be used for fake stitch | ||

| 7 | Punching Die | SKD11 | HRC58-60 | |

| 8 | Electronic Control System | PLC programmed,with touch screen fully automatic control system |

Features of Ceiling T Bar Machine

1. Various sizes, pitches and profile sections are available. 2. Complex profiles with special shapes can also be produced. 3. Economical or high-capacity ceiling t bar machines can be provided. 4. Special or mixed ceiling t bar machines for main t and cross t. 5. Innovative solutions for ceiling t bar machines that meet various needs. |  |

Application of Ceiling T Grid Machines

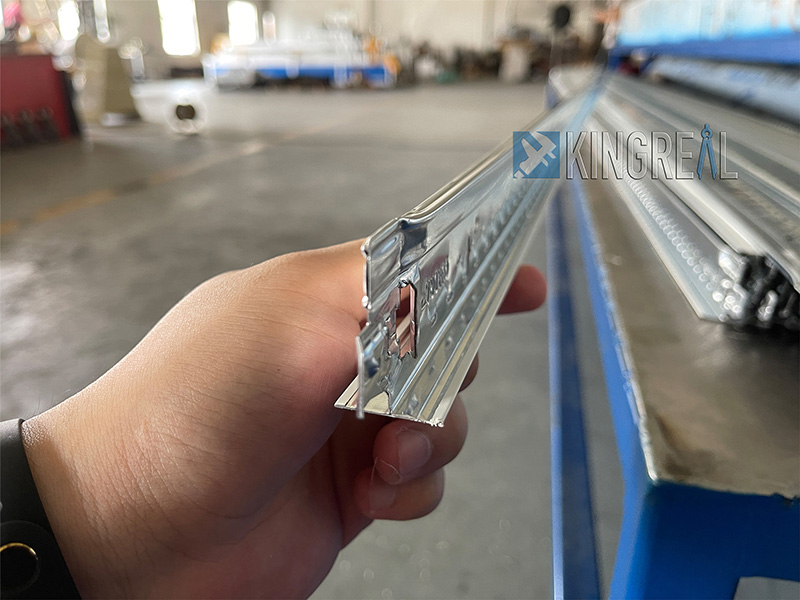

Ceiling t bar is a low-cost, easy-to-install and retrofittable ceiling tile system. There are many styles and patterns to choose from. The design of ceiling t grid allows each structure to be connected to each other without knotting or screwing in. Simply connect the small grid system to the main t and then connect the gypsum board to the ceiling t bar. This makes installation simple, and the tiles can be installed and removed as needed using the instant locking function of the ceiling t bar. Ceiling t bar are thermally insulated, and the tiles are also easy to remove when the ceiling tile system needs repair or replacement. KINGREAL CEILING MACHINERY ceiling t grid machines can produce perfect ceiling t grids. |  |

Quality Assurance

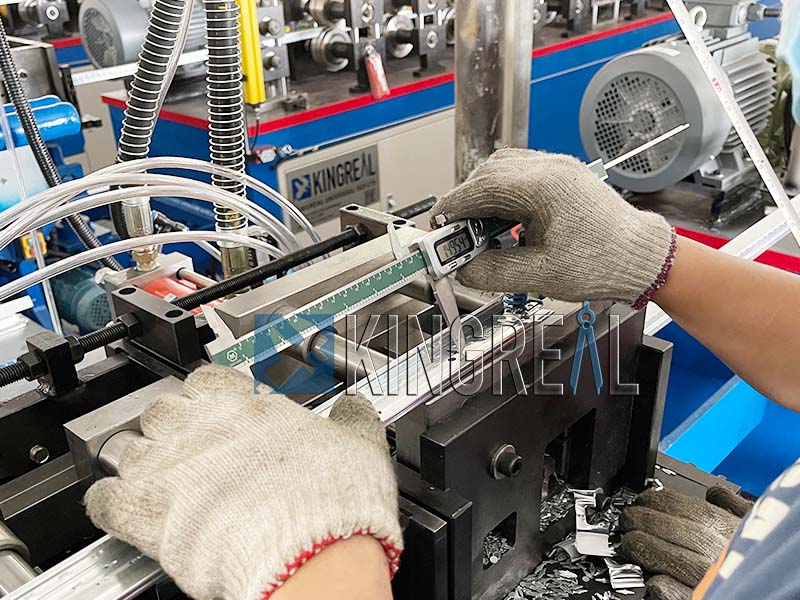

After manufacturing, each ceiling t grid machine of KINGREAL CEILING MACHINERY will go through a series of rigorous testing processes. Engineers will measure the width and height of the finished product. Only the ceiling t bar machine that can produce high-precision, smooth and burr-free finished products that meet the customer's size requirements will be sent to the customer's factory.

Successful Ceiling T Bar Machine Case

So far, KINGREAL CEILING MACHINERY has worked closely with customers from Russia, India, Algeria, Qatar, Canada and other countries. KINGREAL CEILING MACHINERY warmly welcomes customers from all over the world to visit the ceiling t bar machine at KINGREAL CEILING MACHINERY factory, and encourages customers to try to operate the ceiling t bar machine in person for experience, and can also test the finished product. It is precisely because KINGREAL CEILING MACHINERY is confident in the quality and precision of the ceiling t bar machine it can provide that it can do this. |  |

Why Choose KINGREAL CEILING MACHINERY Ceiling T Bar Machine?

Tags: ceiling t bar machine, ceiling t grid machine, flat t grid machine, black line t bar machine, fut ceiling t grid machine, silhouette groove ceiling t grid machine, ceiling t grid wall angle machine, ceiling wall angle making machine, l angle profile roll forming machine, suspended ceiling wall angle machine, ceiling grid wall angle machine

Get the latest price? We'll respond as soon as possible(within 12 hours)