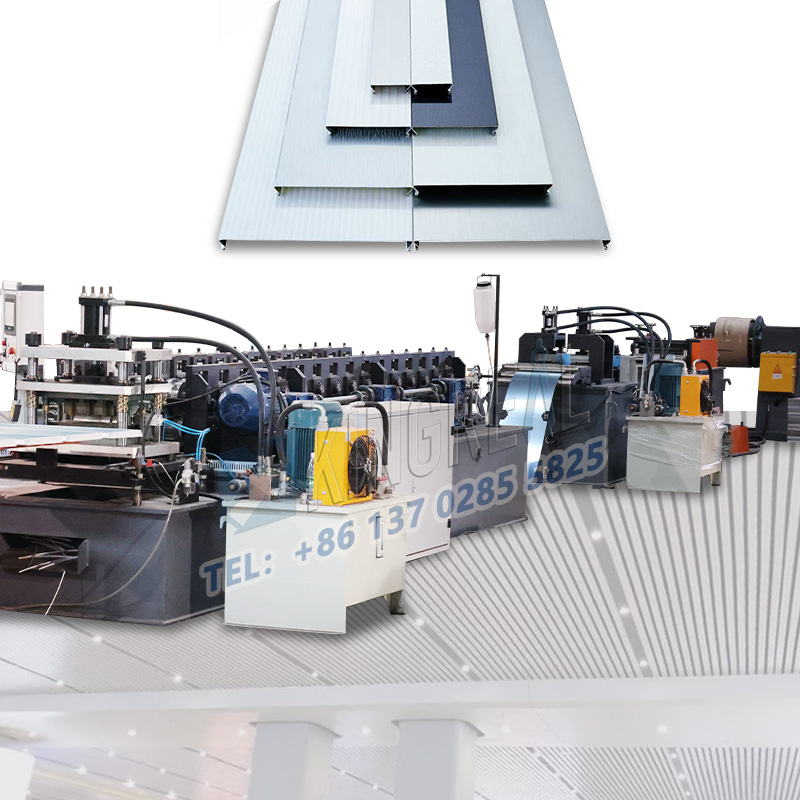

Metal Ceiling Carrier Making Machine

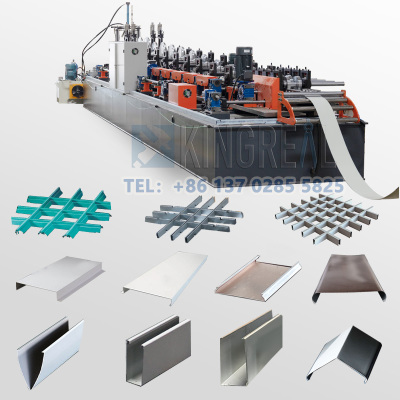

KINGREAL CEILING MACHINERY metal ceiling carrier roll forming machine is used in conjunction with a baffle ceiling making machine or a linear strip ceiling machine, produces high-quality metal ceiling carriers and suspended ceiling panels, creating a complete suspended ceiling system.

- KINGREAL CEILING MACHINERY

Details

Video About Metal Ceiling Carrier Making Machine

Description of Metal Ceiling Carrier Making Machine

KINGREAL CEILING MACHINERY metal ceiling carrier making machine is ideal for installing suspended ceiling systems in modern architecture and interior design. This metal ceiling carrier roll forming machine, when used in conjunction with a baffle ceiling making machine or a linear strip ceiling machine, produces high-quality ceiling carriers and suspended ceiling panels, creating a complete suspended ceiling system. KINGREAL CEILING MACHINERY metal ceiling carrier making machines are widely used in various applications, including hotels, offices, public spaces, and building material shelves.

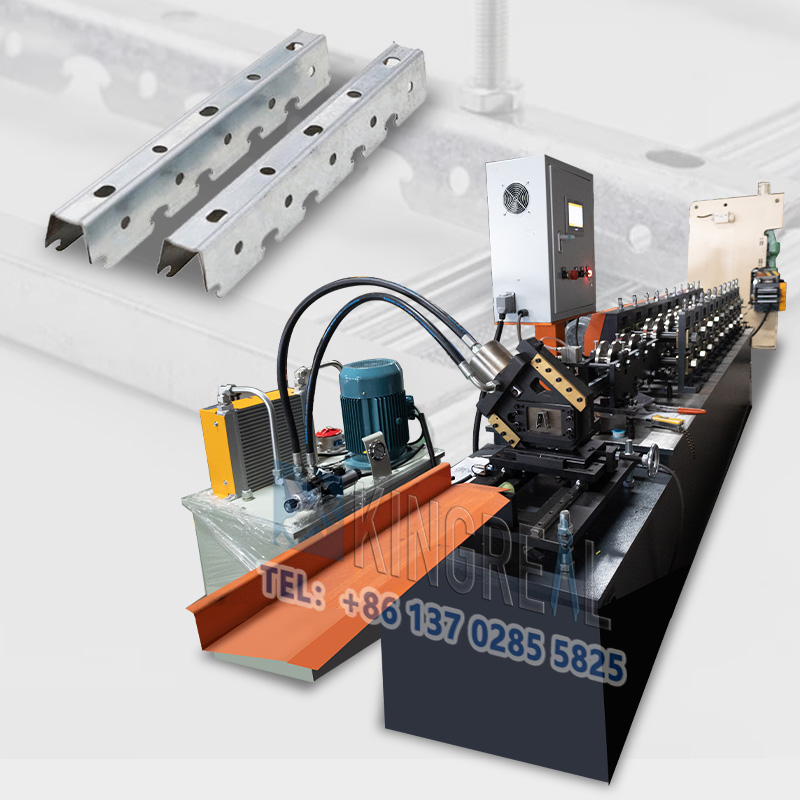

The KINGREAL CEILING MACHINERY metal ceiling carrier roll forming machine consists of several key components, including a 2-in-1 decoiler & leveler, a high-speed punching machine, a roll forming machine, a hydraulic cutting station, an output table, and an electrical control panel. The entire metal ceiling carrier making machine is highly automated, enabling fast and efficient clip production, with outstanding performance and excellent forming quality. |  |

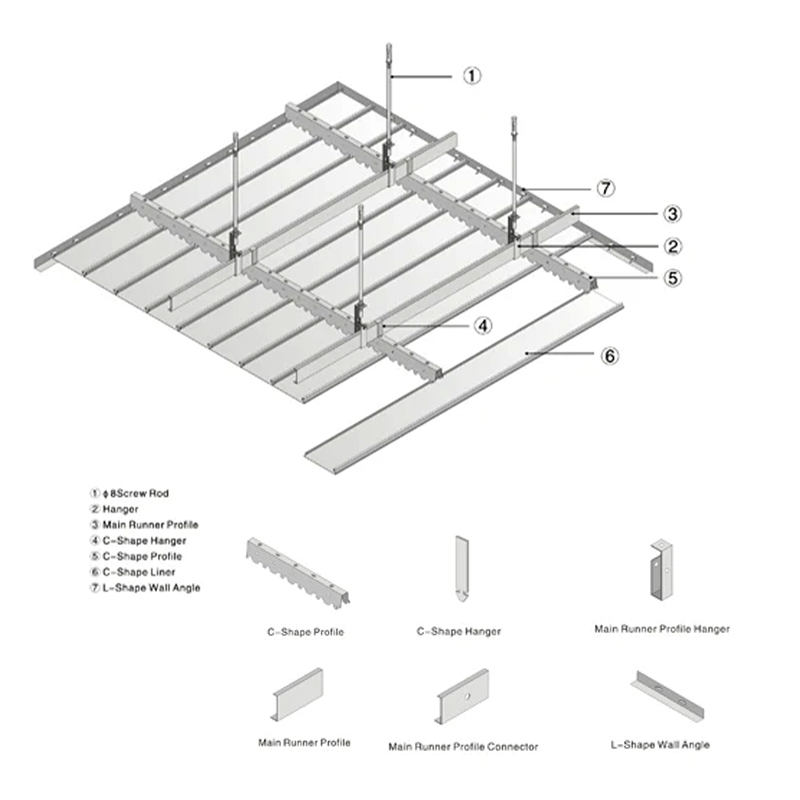

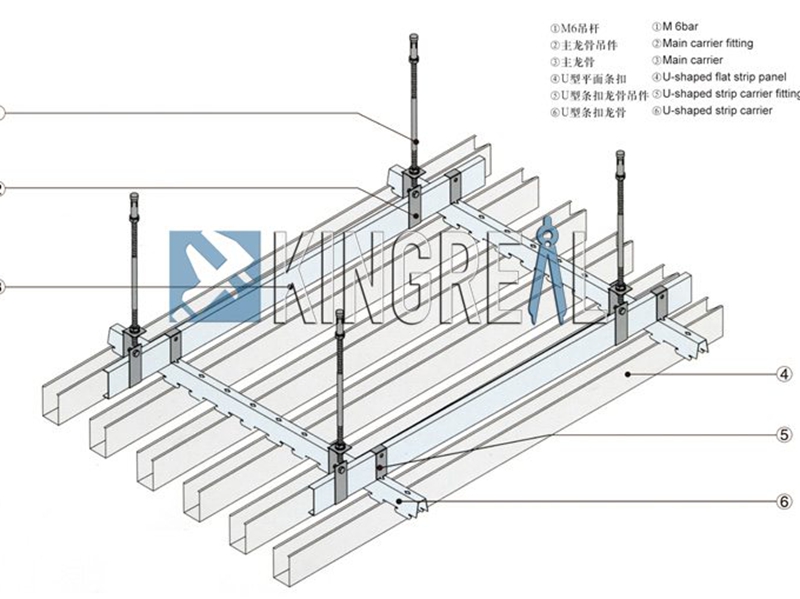

Complete Suspended Ceiling System Solutions

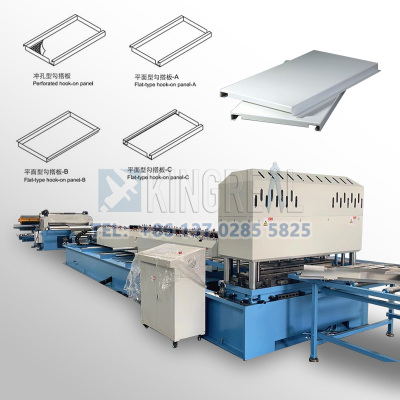

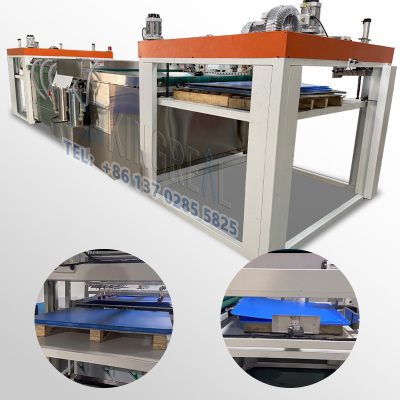

KINGREAL CEILING MACHINERY not only offers high-performance metal ceiling carrier roll forming machines, but also offers baffle ceiling making machine and linear strip ceiling machine, creating an integrated suspended ceiling system solution. The advantage of this combination is that customers can purchase both machines from the same supplier, ensuring a perfect match for each other, resulting in a seamless production and installation process. KINGREAL CEILING MACHINERY metal ceiling carrier making machines can efficiently assemble baffle ceiling carriers or linear strip ceiling carriers with baffle ceiling or linear strip ceiling produced using baffle ceiling machine or linear strip ceiling machine, creating a seamless suspended ceiling system.

KINGREAL CEILING MACHINERY metal ceiling carrier roll forming machines and baffle ceiling machine or linear strip ceiling machine not only shorten installation time and improve construction efficiency, but also reduce labor costs, helping customers quickly respond to market demands. KINGREAL CEILING MACHINERY team of engineers can precisely design and customize each metal ceiling carrier making machine based on specific customer drawings, ensuring that each metal ceiling carrier roll forming machine is perfectly suited to their production needs. This efficient equipment combination allows customers to gain significant advantages in their production processes and enhance their overall competitiveness.

Workflow of Metal Ceiling Carrier Making Machine

2-in-1 Decoiler & Leveling Machine --Punching Machine -- Roll Forming Machine -- Cutting Station -- Output Table

Parameter of Metal Ceiling Carrier Making Machine

| List | Name | Specification | Remark | |

1 | Raw Material | Type | GI Steel Strip | |

| Material Thickness | 0.5-0.7mm for metal ceiling carrier | |||

| Yield Strength | G300-G450 comply with international Standard | |||

| 2 | Production Speed | 5-15m/min for metal ceiling carriers | ||

3 | Products Accuracy | Shearing Accuracy | ±1.0mm (There is a little deformation due to the material stress) | Related with material quality |

| Straightness | Bending is less than 1‰/M, twist is less than 1.3%/M | |||

| Product Section Size | According with drawing or Sample | |||

| Surface Quality | No obvious shrink, irregularity, scratch, spur etc. | |||

| 4 | Roll Forming main motor power | 7.5kw | According to actual design | |

| 5 | Hydraulic Station Motor Power | 4kw | According to actual design | |

| 6 | Power Supply | AC380V, 50HZ, 3phase 4 Lines | ||

| 7 | Total Power | According to actual design | ||

Features of Metal Ceiling Carrier Roll Forming Machine

2-in-1 decoiler &leveler for metal ceiling carrier making machine

The KINGREAL CEILING MACHINERY metal ceiling carrier roll forming machine is equipped with a 2-in-1 decoiler & leveler. It utilizes a hydraulic tensioner and can handle up to 1,500 kg of metal coils. This equipment design ensures efficient decoiling and leveling processes. The inner diameter can be adjusted from 460mm to 520mm, with a maximum outer diameter of 1,400mm. The leveler's leveling rollers are made of GCr15 and undergo a tempering heat treatment, fine grinding, chrome plating, and polishing process, ensuring high precision and stability during the leveling process.

Punching machine for metal ceiling carrier roll forming machine

The KINGREAL CEILING MACHINERY metal ceiling carrier making machine features a high-speed punching machine equipped with a set of dedicated stamping dies. These dies are designed and manufactured according to customer-provided drawings using high-quality wire-cutting technology and a core material of Cr12MoV, ensuring punching accuracy and durability.

Roll forming machine for metal ceiling carrier making machine

The roll forming machine is a key piece of metal ceiling carrier roll forming machine that automatically forms perforated materials into the desired shape. The rollers are made of Cr12mov die steel, heat-treated to a hardness of HRC 58°-60°, ensuring efficient forming and wear resistance. CNC machining ensures the rollers achieve extremely high forming precision, enabling the production of clips that meet customer specifications.

Hydraulic cutting station for metal ceiling carrier making machine

The hydraulic cutting station utilizes servo-controlled, non-stop shearing technology. Its blades are made of D2 material, hardened to HRC 60. This design makes the shearing process more efficient and significantly improves production continuity and stability.

Advantages of Metal Ceiling Carrier Roll Forming Machine

1)Highly automated metal ceiling carrier roll forming machine

KINGREAL CEILING MACHINERY metal ceiling carrier making machines feature a high degree of automation. Equipped with a PLC control panel, the metal ceiling carrier roll forming machine allows users to easily adjust production parameters, including hole spacing, output settings, and production speed. The metal ceiling carrier roll forming machine automatically completes the production process, reducing manual intervention and improving production efficiency. When the metal ceiling carrier making machine reaches the set output, it automatically shuts down, ensuring safe and convenient operation.

2)Customized punching dies for metal ceiling carrier making machine

KINGREAL CEILING MACHINERY can fully customize punching dies, including hole pattern and diameter, according to customer drawings. This flexible design ensures the finished product perfectly fits the suspended ceiling, avoiding deviations or mismatches caused by mismatched dies.

3)Punching machines with suitable tonnage

Based on the customer's specific needs, KINGREAL CEILING MACHINERY will provide a punching machine with a suitable tonnage, such as 25 tons or 45 tons. This selection is based on parameters such as hole pattern, material width, material type, and thickness, ensuring that resources are not wasted or punching is impossible. KINGREAL CEILING MACHINERY engineers will conduct a professional assessment based on customer needs to ensure the most suitable equipment is configured.

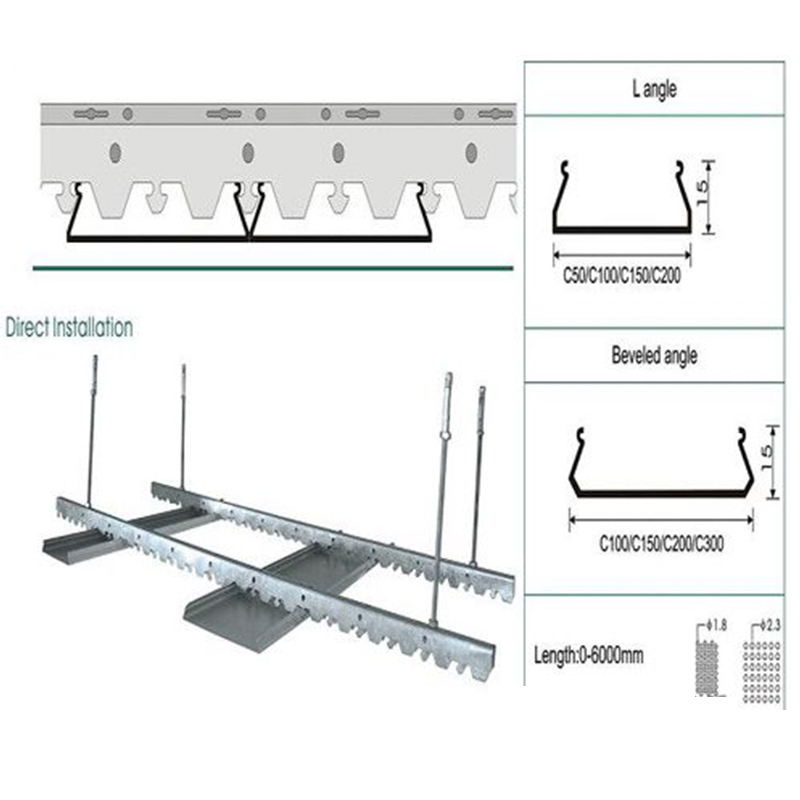

Drawing of Metal Ceiling Carrier

KINGREAL CEILING MACHINERY metal ceiling carrier making machines can produce various types and specifications of metal ceiling carriers for a wide range of suspended ceiling applications. For example, they are suitable for linear strip ceilings of various sizes, such as 84R, 75C, 150C, and 225C, as well as various sizes of baffle ceilings. Whatever KINGREAL CEILING MACHINERY customers' needs are, KINGREAL CEILING MACHINERY can provide efficient and reliable production solutions.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)