How to improve the quality of baffle ceiling machine?

2025-09-02 17:00

The baffle ceiling machine is one of KINGREAL CEILING MACHINERY specialty suspended ceiling machines, specifically designed for producing high-precision, burr-free baffle ceilings. With ever-changing market demands, customers often compare manufacturers when considering u-shape baffle ceiling machines, placing particular emphasis on machine quality. As a baffle ceiling making machine manufacturer with over two decades of experience, KINGREAL CEILING MACHINERY has established rigorous processes across all stages of its design, R&D, manufacturing, and testing processes to ensure the high quality of its baffle ceiling machines.

After u-shape baffle ceiling machine manufacturing is complete, commissioning is a critical step in ensuring quality. This allows manufacturers to verify baffle ceiling making machine performance and the quality of the finished product, identifying potential issues and enabling timely adjustments. KINGREAL CEILING MACHINERY employs two primary commissioning methods to meet diverse customer needs.

Strict Testing Process for Baffle Ceiling Machine

1. Inviting Customers for In-Person Commissioning

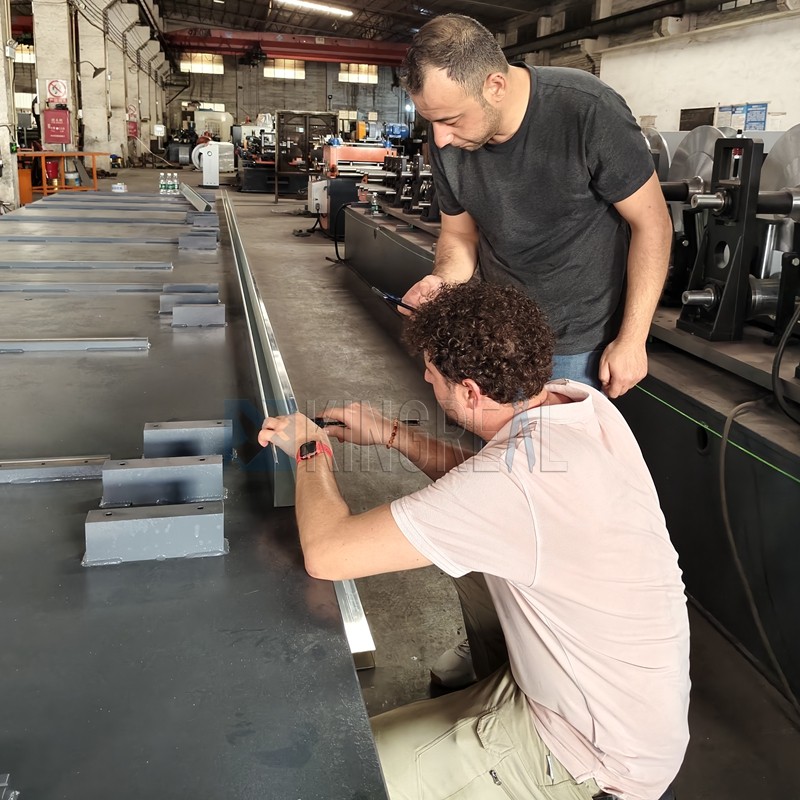

After manufacturing a baffle ceiling machine, KINGREAL CEILING MACHINERY warmly invites customers to visit its factory for a commissioning session. This process not only allows customers to experience the u-shape baffle ceiling machine in action, but also allows them to personally measure the dimensions of the baffle ceiling making machine components and verify the precision of the finished product.

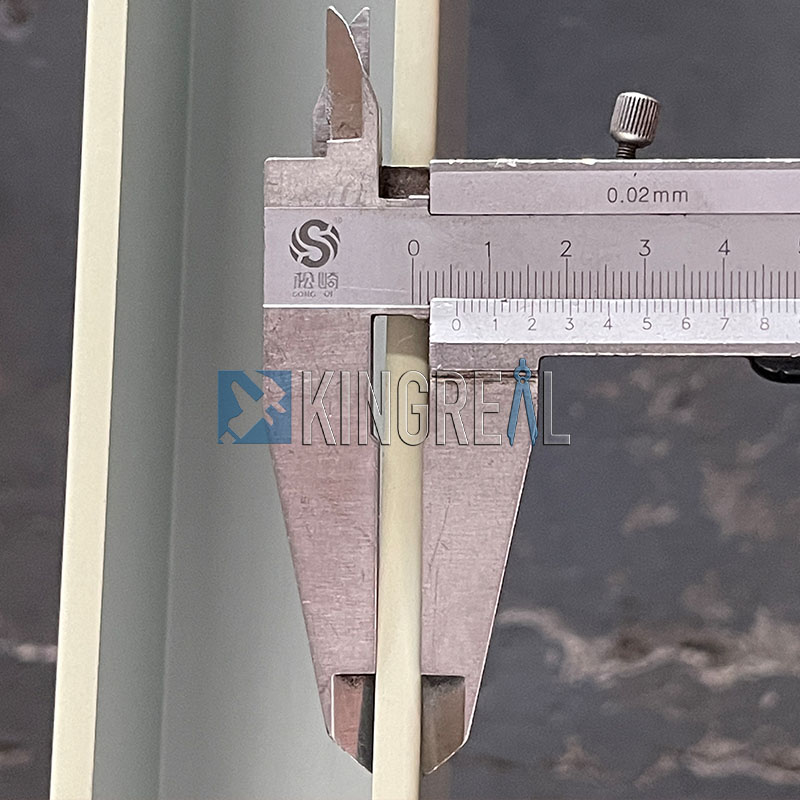

For example, in August of this year, KINGREAL CEILING MACHINERY welcomed a customer from Turkey. During the baffle ceiling making machine trial, the two Turkish customers acted very professionally, using a tape measure to measure lengths, calipers to measure cross-sectional dimensions, and an angle ruler to measure angles. Before designing the u-shape baffle ceiling making machine, KINGREAL CEILING MACHINERY engineers proactively inquired about the acceptable tolerances for the finished product, ensuring that the baffle ceiling making machine's final output would fully meet their requirements.

During the actual baffle ceiling machine trial, KINGREAL CEILING MACHINERY staff fully cooperated with the Turkish customers, adjusting parameters and commissioning the u-shape baffle ceiling machine to meet their various requirements. After repeated adjustments, the final product produced by the baffle ceiling making machine boasted a smooth, wave-free surface, a sturdy, deflection-free base, and no roller marks or axial deviation, perfectly meeting the Turkish customers' expectations. This meticulous service and rigorous quality control have earned high satisfaction from the Turkish customers.

2. Remote Baffle Ceiling Machine Trial Via Video

Since many customers are unable to visit the factory in person due to busy schedules, KINGREAL CEILING MACHINERY also offers remote u-shape baffle ceiling machine trial services. Professional engineers will conduct the baffle ceiling making machine trial on behalf of the customer, ensuring that the baffle ceiling machine achieves the expected quality across all parameters.

Before conducting a remote test run, KINGREAL CEILING MACHINERY engineers proactively understand the customer's specific u-shape baffle ceiling machine requirements, including test details and parameter settings. KINGREAL CEILING MACHINERY engineers then commission the baffle ceiling making machine, adjusting production parameters such as speed, width, and finished product height to ensure that the precision of the baffle ceiling machines produced under different conditions meets the customer's standards. The entire test run includes detailed recording and filming. KINGREAL CEILING MACHINERY staff meticulously document every parameter and send the customer a video, images, and test results. This allows customers to gain real-time insights into the u-shape baffle ceiling machine's performance and finished product quality while overseas, ensuring no omissions.

Key Measures for Improving Quality of Baffle Ceiling Machine

1. Rigorous Design and R&D Process

During the design and development phase of u-shape baffle ceiling machines, KINGREAL CEILING MACHINERY engineers fully consider customer needs and market trends. Using advanced computer software, the design team accurately simulates the baffle ceiling making machine's operating performance and conducts multiple optimizations to ensure design rationality and manufacturability.

2. High-Standard Raw Material Selection

The quality of u-shape baffle ceiling machines depends largely on the quality of the materials used. KINGREAL CEILING MACHINERY rigorously controls the procurement of raw materials to ensure that all materials meet international standards. By establishing long-term partnerships with reputable suppliers, KINGREAL CEILING MACHINERY is able to secure stable, high-quality raw materials, laying a solid foundation for the manufacture of its baffle ceiling making machines.

3. Precision Manufacturing Process

During the manufacturing process, KINGREAL CEILING MACHINERY utilizes modern production equipment and processes to ensure the precision of each baffle ceiling machine. Using CNC equipment and automated production lines, each u-shape baffle ceiling machine component meets high precision requirements. Furthermore, every step in the manufacturing process undergoes rigorous quality control to ensure a high pass rate for the final product.

4. Meticulous Inspection and Testing

In addition to baffle ceiling making machine trials, KINGREAL CEILING MACHINERY conducts multiple inspections during the production process. Each component undergoes rigorous quality inspections before assembly to ensure compliance with design specifications. Upon completion, KINGREAL CEILING MACHINERY conducts comprehensive performance testing on the baffle ceiling machine to ensure stable operation in actual production.

4.1 Dimensional and Performance Testing

During the inspection process, KINGREAL CEILING MACHINERY conducts both dimensional and performance testing on the u-shape baffle ceiling machine. Dimensional testing involves precise measurement of the dimensions of each baffle ceiling making machine component to ensure compliance with design requirements. Performance testing involves actual operational testing to ensure stable performance under varying loads.

4.2 Customer Feedback and Improvement

KINGREAL CEILING MACHINERY values customer feedback. After baffle ceiling machine delivery, KINGREAL CEILING MACHINERY regularly communicates with customers to understand their actual baffle ceiling making machine usage and any suggestions. This feedback enables KINGREAL CEILING MACHINERY to continuously improve product design and manufacturing processes, further enhancing the quality of our u-shape baffle ceiling machines.

Get the latest price? We'll respond as soon as possible(within 12 hours)