Metal Perforated Making Machine|2025

2025-07-23 17:00

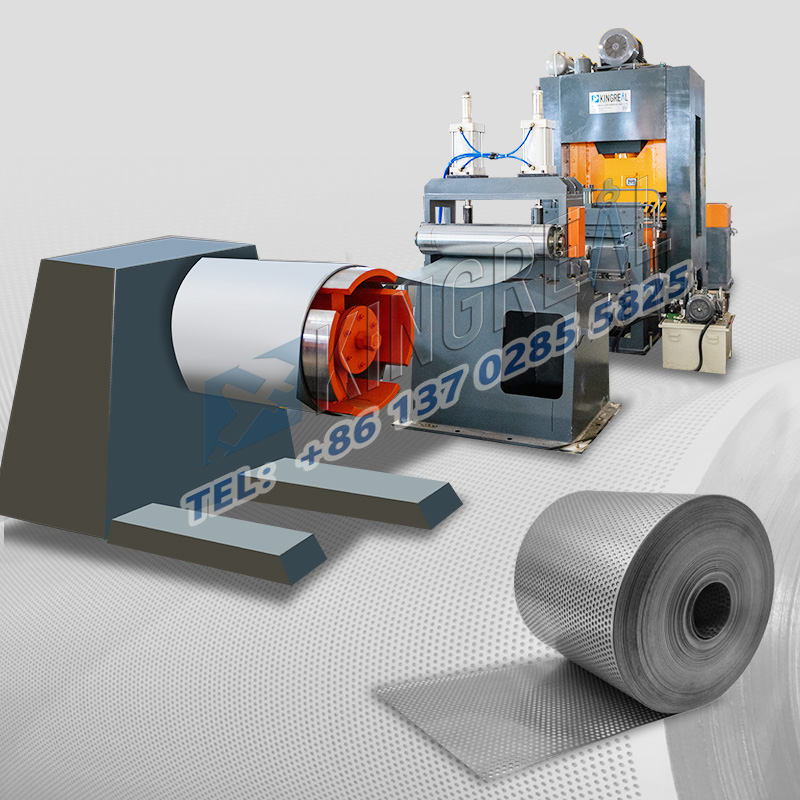

"KINGREAL CEILING MACHINERY metal perforated making machine can punch out different hole shapes and diameters on the surface of various metal coils, and is suitable for a variety of raw materials such as iron, stainless steel, copper, aluminum, galvanized, etc.

KINGREAL CEILING MACHINERY steel perforated machine is custom designed and manufactured according to the drawings provided by customers and actual production needs to meet the specific requirements of different industries."

1. Advantages of KINGREAL CEILING MACHINERY Metal Perforated Making Machine

1.1 Diverse performance and parameter configuration KINGREAL CEILING MACHINERY steel perforated machine consists of an decoiler, a precision straightener, a metal punching machine and other high-precision components. According to the specific production process requirements of the customer, the metal perforated making machine can be equipped with a cutting station or a recoiler to flexibly respond to a variety of production scenarios and ensure efficient operation.

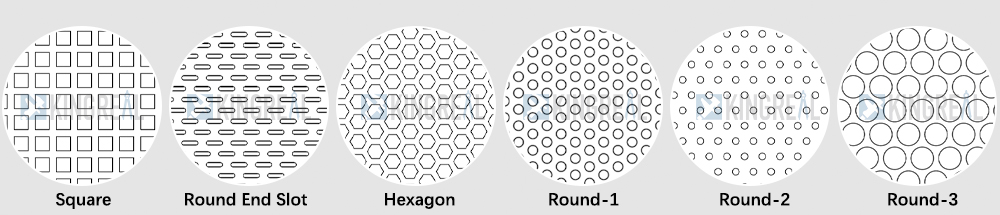

1.2 Highly flexible steel perforated machine KINGREAL CEILING MACHINERY metal perforated making machine can process a variety of hole shapes on metal sheets of different materials, including round holes, oblong holes, square holes, triangular holes, diamond holes, hexagonal holes and cross holes, etc., to form various types of perforated plates. Whether it is the initial punching of raw materials, the processing of semi-finished products, or the final processing of finished products, KINGREAL CEILING MACHINERY can provide comprehensive solutions to ensure that the diverse needs of customers are met. |  |

1.3 High-precision punching technology KINGREAL CEILING MACHINERY strictly controls the manufacturing process of steel perforated machines and uses metal punching machines from the well-known brand Yangli. The cutting station is equipped with high-hardness, high-quality material blades, and the punching mold is customized according to the customer's specific drawings. These measures ensure high-speed and high-precision punching effects, significantly reduce manual intervention, and improve production efficiency.

1.4 Rich experience in steel perforated machine projects Currently, KINGREAL CEILING MACHINERY metal perforated making machines have been successfully exported to Brazil, Turkey, Russia, Saudi Arabia, Greece, Qatar and other countries. KINGREAL CEILING MACHINERY engineers have a deep understanding of the parameter requirements of metal perforated making machines in various markets, and provide comprehensive after-sales services, including machine installation, operation training, troubleshooting and maintenance, to ensure customers' smooth use and efficient production. |  |

2. KINGREAL CEILING MACHINERY Provides Customized Metal Perforated Making Machines

Each KINGREAL CEILING MACHINERY steel perforated machine is unique, with configurations and parameters tailored to the specific needs of customers. KINGREAL CEILING MACHINERY provides reasonable tonnage recommendations based on customer requirements for hole type and hole diameter, combined with material width, type and thickness. Typically, KINGREAL CEILING MACHINERY provides 120-ton, 125-ton, 160-ton and 200-ton punching machines for customers to choose from.

In terms of metal perforated making machine configuration, KINGREAL CEILING MACHINERY will customize steel perforated machine solutions based on customer production process requirements.

For example, if customers need to quickly cut the sheet after punching, KINGREAL CEILING MACHINERY will equip it with an efficient cutting station to design a metal sheet perforated machine;

If customers want to carry out continuous production and realize coiling, KINGREAL CEILING MACHINERY will provide a coil to coil perforation line;

For metal ceiling manufacturers, KINGREAL CEILING MACHINERY can customize a dedicated metal ceiling tile perforation line for use with a metal ceiling tile making machine.

In addition, if the customer requires the surface of the perforated sheet to be cleaned, KINGREAL CEILING MACHINERY can equip the metal perforated making machine with a metal sheet cleaning machine to ensure that it is cleaned immediately after the punching is completed, remove the surface oil and dirt, and achieve a seamless connection between production and cleaning.

Different Hole Type:

3. KINGREAL CEILING MACHINERY Provides One-stop Service

KINGREAL CEILING MACHINERY always provides professional services to customers before, during and after the sale of the steel perforated machine.

3.1 Factory Visit Service

Before customers decide to buy a metal perforated making machine, KINGREAL CEILING MACHINERY will invite customers to visit our factory. Customers can visit the steel perforated machine operation on site, operate the equipment in person, and evaluate whether the KINGREAL CEILING MACHINERY metal perforated making machine meets their production needs.

KINGREAL CEILING MACHINERY staff will introduce the functions and parameters of each component in detail, and display multiple steel perforated machines with different performance and configurations to help customers better understand KINGREAL CEILING MACHINERY ability to customize metal perforated making machines.

3.2 Customized steel perforated machine solution design

KINGREAL CEILING MACHINERY will provide personalized metal perforated making machine manufacturing solutions based on the customer's drawings and actual production conditions, combined with the climate and policy factors in the customer's area. During the design phase, KINGREAL CEILING MACHINERY will dig deep into the needs of customers to ensure that all aspects such as material, material thickness, material width, hole type, hole diameter, purpose and output are covered.

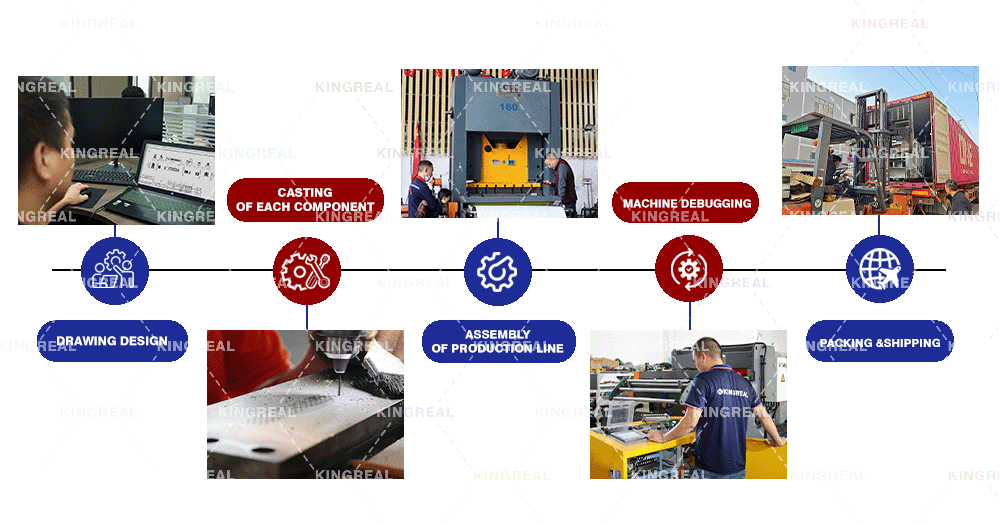

3.3 Precision manufacturing of steel perforated machines

As a metal perforated making machine supplier integrating R&D, manufacturing and sales, KINGREAL CEILING MACHINERY can ensure the quality of the steel perforated machine and deliver it on time. KINGREAL CEILING MACHINERY production process is strictly managed to ensure that each pmetal perforated making machine can meet high standards.

3.4 Professional installation and training of steel perforated machines

After the metal perforated making machine is manufactured and tested, KINGREAL CEILING MACHINERY will send professional engineers to the customer's factory for installation and provide comprehensive training for the operators.

KINGREAL CEILING MACHINERY will also inform the possible problems and solutions encountered in the operation in advance to ensure that customers can use the steel perforated machine smoothly and efficiently.

If you want to know more information about steel perforated machine, please contact KINGREAL CEILING MACHINERY!

Get the latest price? We'll respond as soon as possible(within 12 hours)