New Project: Metal Stamping Making Machine

2026-01-31 17:00

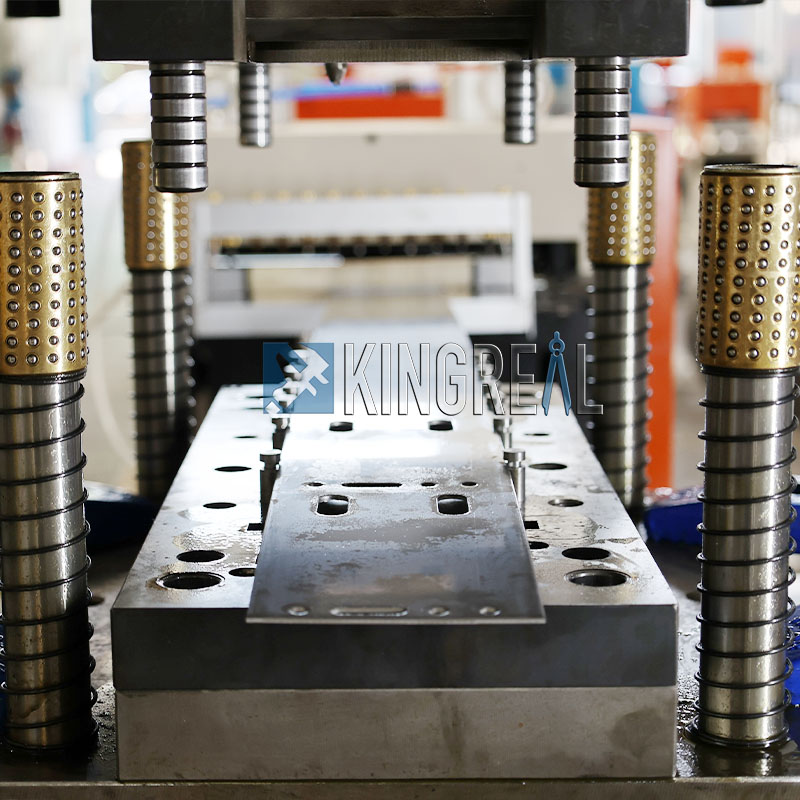

KINGREAL CEILING MACHINERY has always focused on market dynamics and actively responded to the latest project needs of its customers, continuously improving the competitiveness of machines through technological research and development and product innovation. Recently, two metal stamping making machines designed by KINGREAL CEILING MACHINERY for a customer in Turkmenistan have been manufactured and are currently undergoing commissioning. This metal stamping press will provide an efficient and precise solution for the customer's suspended ceiling project in Turkmenistan.

Metal Stamping Making Machine Project Background

The design of this metal stamping press originated from the specific needs of the customer in Turkmenistan. During the initial communication, the customer provided KINGREAL CEILING MACHINERY with finished product samples and drawings, and explained the intended use in detail. They wanted to produce angle brackets for suspended ceiling projects to bear the load and wind pressure of the building, ensuring the overall stability and safety of the suspended ceiling.

Based on these requirements, the KINGREAL CEILING MACHINERY team fully considered various challenges in the actual application of the equipment when designing the metal stamping making machine. Especially in the design of the progressive die for the metal stamping press, KINGREAL CEILING MACHINERY strived to achieve multi-process one-time forming to reduce errors that might be caused by secondary clamping, thereby improving production efficiency. For the specific materials the customer needed to process, KINGREAL CEILING MACHINERY designed an adjustable bending slider to ensure the consistency of the bending angle and avoid angle deviations caused by material springback. Therefore, KINGREAL CEILING MACHINERY quickly provided the customer in Turkmenistan with a customized metal stamping making machine manufacturing solution, and both parties successfully reached a cooperation agreement after confirming the solution.

Innovative Solutions for Metal Stamping Press

1)Customized progressive die

For the specific needs of the customer in Turkmenistan, KINGREAL CEILING MACHINERY specially customized a progressive die based on the design concept of the angle bracket. This die design integrates multiple processes such as blanking, punching, and bending, and all stamping processes can be completed at different stations of the same progressive die. This design not only ensures that the sheet metal is processed from feeding to finished product without manual clamping, but also completely avoids hole position deviations and bending angle deviations that may be caused by multiple clamping, thus ensuring dimensional consistency and fully meeting the high precision requirements of wall angle brackets.

2)High speed production

To improve production efficiency, KINGREAL CEILING MACHINERY metal stamping press is equipped with a servo feeder, enabling automated continuous stamping. This technology far surpasses the intermittent production mode of traditional single-process molds, perfectly matching the large demand and tight delivery schedule characteristics of the Turkmenistan customer's single project. This not only significantly improves production efficiency but also makes mass production possible, ensuring that the Turkmenistan customer's production needs during peak periods are met in a timely manner.

3)Highly automated

KINGREAL CEILING MACHINERY metal stamping making machine consists of multiple components, including a decoiler, a leveling machine, and a punch press machine, achieving highly automated production. During the production process, workers only need to organize the angle brackets produced by the metal stamping press and monitor the metal stamping making machine to prevent any special circumstances. In addition, the metal stamping press is equipped with a fault alarm function; if the metal stamping making machine detects an abnormal situation, it will immediately trigger an alarm, promptly reminding workers and preventing mold damage or defective products.

Metal Stamping Press Trialing and Subsequent Steps

Subsequently, KINGREAL CEILING MACHINERY will invite the Turkmenistan customer to the factory for a trial run. During the trial run, the Turkmenistan customer can personally witness the metal stamping making machine's operation and the quality and precision of the final product. If the Turkmenistan customer has any questions during the trial run, KINGREAL CEILING MACHINERY engineers will trial the metal stamping press in real time to ensure that the metal stamping making machine fully meets the Turkmenistan customer's project requirements. After the trial run is completed, if the Turkmenistan customer is satisfied with the metal stamping press's performance, the shipping phase will begin. At this time, KINGREAL CEILING MACHINERY will carry out meticulous packaging to ensure the safety and integrity of the metal stamping making machine during transportation.

Get the latest price? We'll respond as soon as possible(within 12 hours)