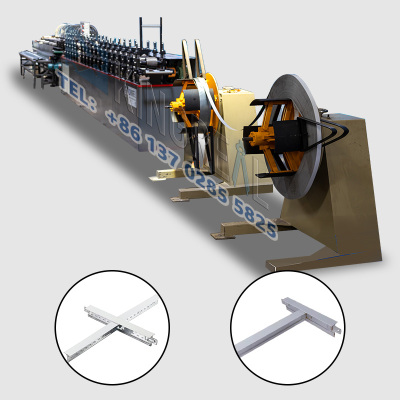

Ceiling T Grid Wall Angle Machine

KINGREAL CEILING MACHINERY specializes in providing a wide range of fully automatic ceiling t grid wall angle machines, designed to produce metal ceiling grid wall molding of various specifications, providing additional support and aesthetics for lay-in ceiling systems.

This ceiling grid wall angle machine not only improves production efficiency but also significantly enhances product forming accuracy.

- KINGREAL CEILING MACHINERY

- CHINA

Details

Video About Ceiling T Grid Wall Angle Machine

Description of Ceiling T Grid Wall Angle Machine

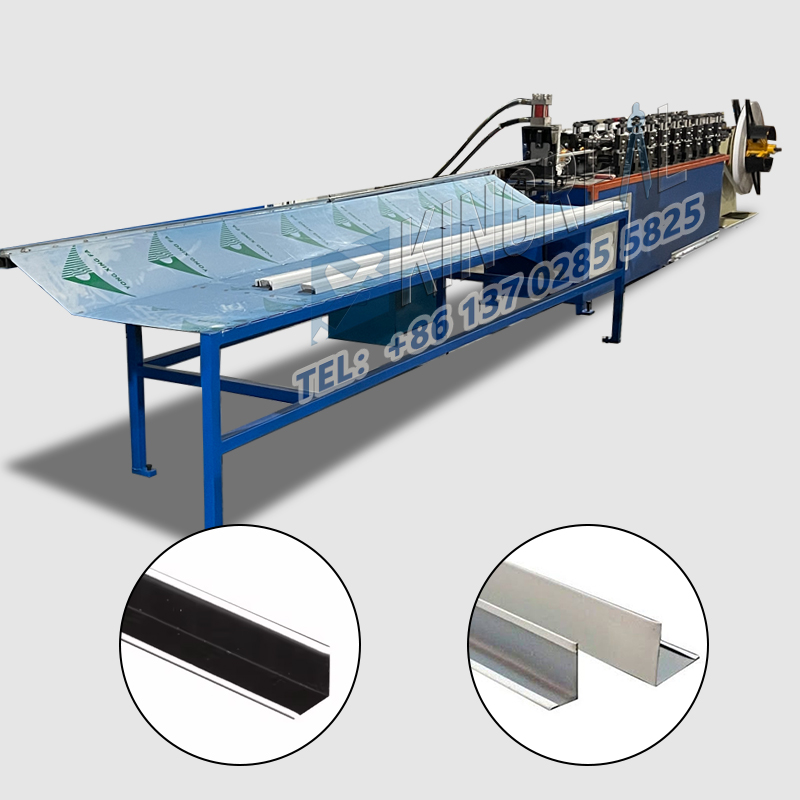

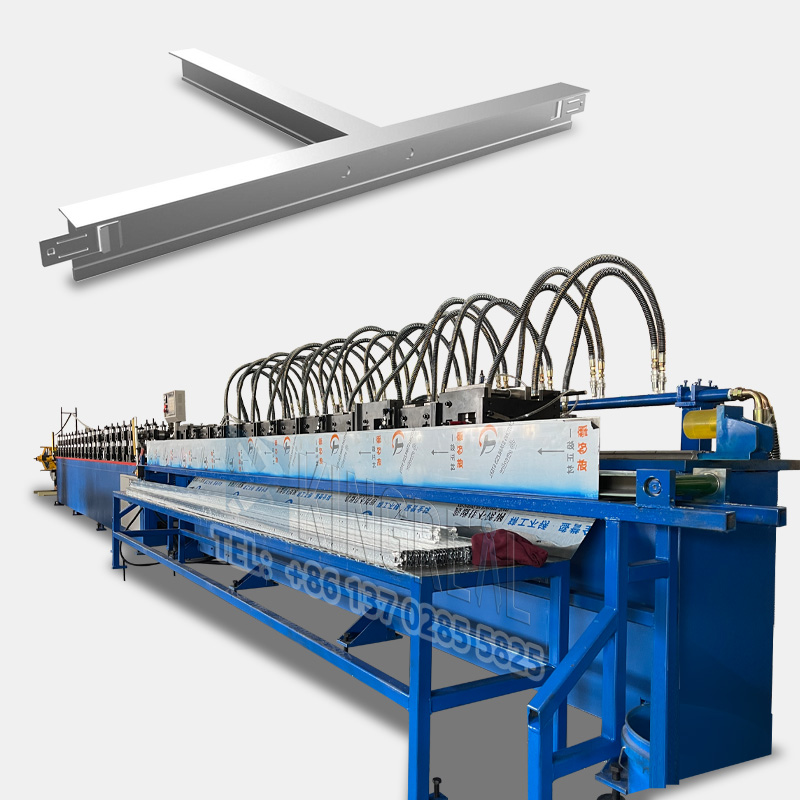

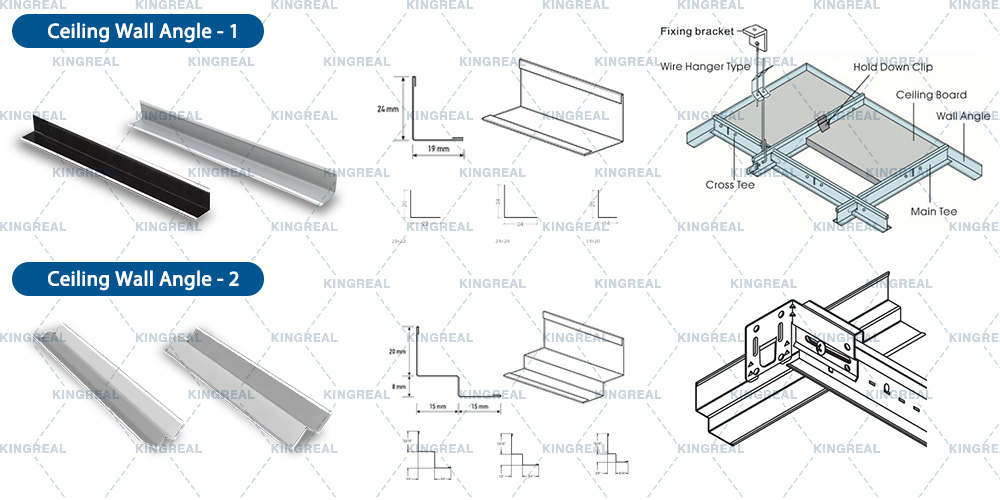

KINGREAL CEILING MACHINERY specializes in providing a wide range of fully automatic ceiling t grid wall angle machines, designed to produce metal ceiling grid wall molding of various specifications, providing additional support and aesthetics for lay-in ceiling systems. KINGREAL CEILING MACHINERY ceiling grid wall angle machines effectively secure ceiling edges, preventing material deformation or sagging during use, thereby ensuring the stability and safety of the entire ceiling system.

Each ceiling t grid wall angle machine is custom-designed based on the customer's drawings and actual production needs. During the design process, KINGREAL CEILING MACHINERY engineers carefully consider factors such as raw material thickness, processing material characteristics, and the required metal ceiling grid wall molding length to ensure the ceiling t grid wall angle machine meets the customer's production requirements. Through fully automated production processes, this ceiling grid wall angle machine not only improves production efficiency but also significantly enhances product forming accuracy, giving customers a competitive advantage. |  |

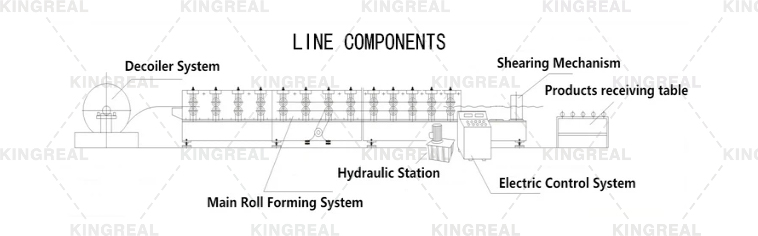

Working Process of Ceiling T Grid Wall Angle Machine

Decoiler- Roll Forming Machine - Cutting Station- Output Table

Advantages of Ceiling Grid Wall Angle Machine

1. PLC system of ceiling t grid wall angle machine

KINGREAL CEILING MACHINERY ceiling grid wall angle machines are equipped with an advanced PLC control system, enabling flexible adjustment of production speed, cutting length, and output settings. Through precise parameter settings, operators can monitor the ceiling t grid wall angle machine's operating status in real time, ensuring efficient and stable production.

2. High precision ceiling grid wall angle machine

This ceiling t grid wall angle machine utilizes a high-precision servo motor and drive system, combined with an independent arch design, ensuring a stable and reliable machine frame and support structure. Highly rigid components effectively withstand the pressure of the process, ensuring stability during the forming process and minimizing any potential errors.

3. Following cutting system for ceiling grid wall angle machine

The cutting station is equipped with a following cutting system, enabling quick and accurate cutting to the customer's preset length. This system ensures consistent finished product quality when producing the same product multiple times, significantly reducing material waste and improving production efficiency.

Parameters of Finished Product

| Product name | Specification(mm) | Thickness |

| Main tee | 38x24x3600(3660) 32x24x3600(3660) | 0.25,0.27,0.30,0.35mm |

| Cross tee | 26x24x1200(1220) 24x24x1200(1220) | 0.25,0.27,0.30,0.35mm |

| Cross tee | 26x24x600(610) 24x24x600(610) | 0.25,0.30,0.35,0.40mm |

| Wall angle | 22x22x3000 24x24x3000 | 0.25,0.30,0.35,0.40mm |

Complete Ceiling System Solutions

KINGREAL CEILING MACHINERY not only provides ceiling t grid wall angle machines, but also offers customers a complete ceiling system solution. This includes lay in ceiling tile production lines, ceiling t grid machines, and ceiling grid wall angle machines, helping customers achieve efficient production and installation of suspended ceiling systems.

●Lay in ceiling tile production line

KINGREAL CEILING MACHINERY lay in ceiling tile production lines offer both fully automatic and semi-automatic modes, equipped with additional equipment such as a metal sheet cleaning machine, acoustical ceiling tile textile stick machine. Compatible with both aluminum and steel materials, they can produce metal ceiling panels of various specifications to meet diverse customer needs.

KINGREAL CEILING MACHINERY ceiling t grid machine can produce a variety of main t and cross t in various sizes and types, including flat t grid, center black line t bar, FUT ceiling t grid, and silhouette groove ceiling t grid. Each type of ceiling t bar offers advantages in load-bearing capacity and aesthetics, meeting the specific needs of customers for different applications.

●Ceiling t grid wall angle machine

KINGREAL CEILING MACHINERY ceiling grid wall angle machine specialize in producing metal ceiling grid wall molding of various sizes. These ceiling grid wall angle machines, when used in conjunction with ceiling t bar in ceiling systems, provide an efficient and stable solution.

Installation of Metal Ceiling Grid Wall Molding

When using metal ceiling grid wall molding produced by ceiling grid wall angle machines, the installation and application steps are equally crucial:

-Securing the metal ceiling grid wall molding: First, install the metal ceiling grid wall molding around the perimeter of the ceiling, ensuring it is level and securely fastened to the wall. This is fundamental to the stability of the ceiling system.

-Hanging the Main T: Using hangers and wire, hang the Main t at fixed intervals from the overhead structure, ensuring the alignment and levelness of the Main T.

-Inserting the Cross T: Insert the Cross T at right angles into the slots of the Main T to form a grid-like structure, and securely snap or lock it into place.

-Laying in the Ceiling Panels: Finally, carefully place the 600x600mm or 600x1200mm ceiling panels into the grid openings, ensuring a snug fit without squeezing or damaging the grid structure.

-Adjust as needed: After installation, make necessary adjustments to ensure uniform tile spacing and alignment within the grid system.

Through these steps, the metal ceiling grid wall molding produced using the ceiling grid wall angle machine will integrate seamlessly with the ceiling system, providing stable support and an aesthetically pleasing appearance.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)