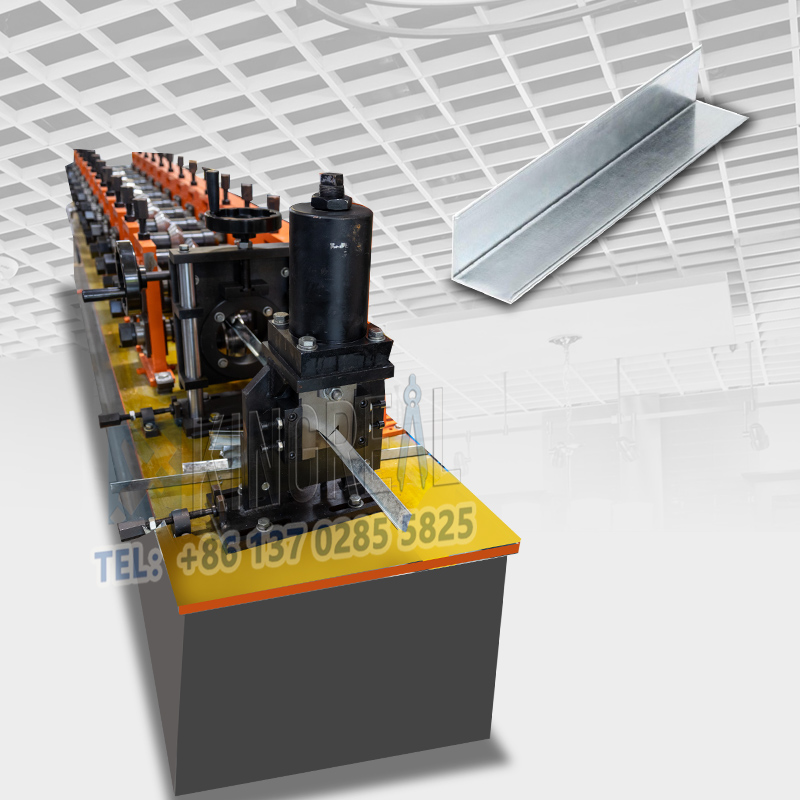

L-Shaped Profile Making Machine

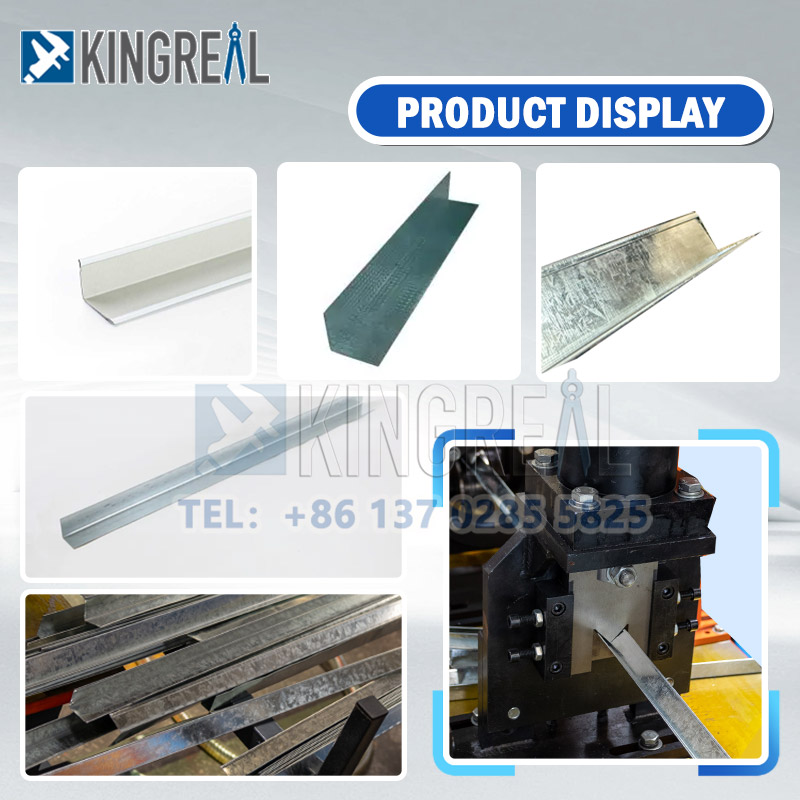

This L-Shaped Profile Making Machine is specifically designed for processing Gi Strip and PPGI raw materials, capable of producing 24x24mm and 19x19mm Wall-mounted L-profiles in lengths up to 3000mm. It is an essential component for open cell ceiling installation. In conjunction with open cell ceiling, sheet metal punching machine, and other equipment, the high-precision finished products produced by this L Angle Profile Roll Forming Machine effectively support the open cell ceiling structure and enhance overall construction quality.

- KINGREAL CEILING MACHINERY

Details

Description of L-Shaped Profile Making Machine

This L-Shaped Profile Making Machine is specifically designed for processing Gi Strip and PPGI raw materials, capable of producing 24x24mm and 19x19mm Wall-mounted L-profiles in lengths up to 3000mm. It is an essential component for open cell ceiling installation. In conjunction with open cell ceiling machine, sheet metal punching machine, and other equipment, the high-precision finished products produced by this L Angle Profile Roll Forming Machine effectively support the open cell ceiling structure and enhance overall construction quality.

KINGREAL CEILING MACHINERY is committed to providing customers with complete open cell ceiling system solutions. KINGREAL CEILING MACHINERY can customize a variety of L Angle Profile Roll Forming Machines based on customer requirements, product specifications, types, and production scale. These L-Shaped Profile Making Machines vary in parameters and performance to meet customers' highest demands for output, quality, efficiency, and automation. KINGREAL CEILING MACHINERY L Angle Profile Roll Forming Machines not only produce the high-precision Wall-mounted L-profiles that meet customer needs, but also achieve a maximum production speed of 30m/min, ensuring fast and efficient production.

Working Process of L Angle Profile Roll Forming Machine

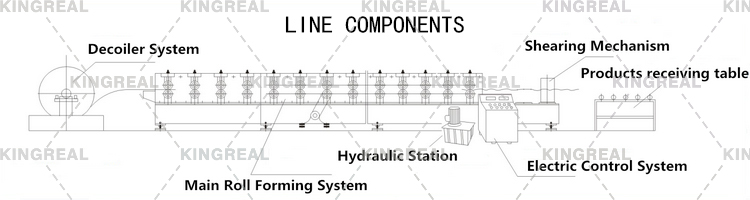

Hydraulic Decoiler--Main Roll Forming Machine--Cutting Station--Output Table

Parameters of L-Shaped Profile Making Machine

| List | Name | Specification | Remark | |

1 | Raw Material | Type | GI Strip and PPGI | |

Material Thickness | 0.3-0.4mm Gi Steel | Thickness increased based on products size | ||

Yield Strength | Comply with international Standard | |||

| 2 | Production Speed | 0-30m/min Adjustable for L Angle Profile Roll Forming Machine | ||

3 | Product Accuracy | Product Section Size | According with drawing or Sample | |

| Surface Quality | No obvious shrink, irregularity, scratch, spur etc. | |||

| 4 | Power Supply | AC415V, 50HZ, 3-Phases or to be customized as per request |

Main Components of L-Shaped Profile Making Machine

1)Decoiler for L-Shaped Profile Making Machine

KINGREAL CEILING MACHINERY passive decoiler for the L Angle Profile Roll Forming Machine efficiently decoils raw material and produces galvanized steel strip. The decoiler can handle coils up to 500 kg, with an inner diameter range of 450-530 mm and an outer diameter of up to 1300 mm, ensuring a stable supply of material.

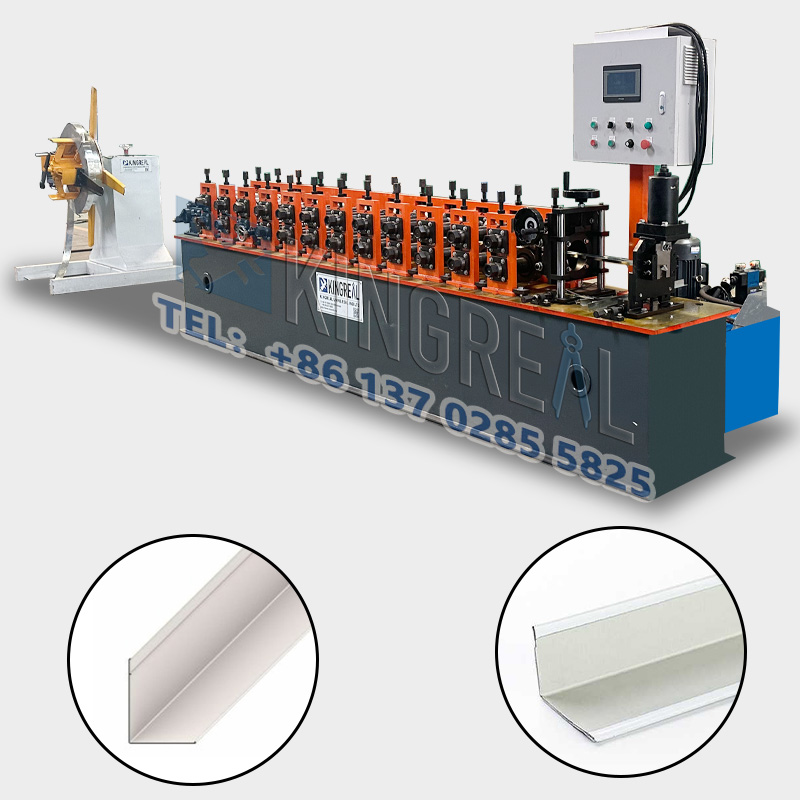

2)Roll Forming Machine for L-Shaped Profile Making Machine

The forming unit of the L Angle Profile Roll Forming Machine is equipped with a 40 mm diameter shaft, CR12 steel rollers, and 9rollers group. The main motor is a 3.0 kW all-copper wire motor with a chain drive. The production speed is adjustable up to 30 m/min, allowing users to adjust the speed based on actual production conditions and enhance production flexibility.

3)Cutting Station for L-Shaped Profile Making Machine

KINGREAL CEILING MACHINERY has equipped the L Angle Profile Roll Forming Machine's cutting station with high-performance components, including CR12 steel cutting blades, to ensure precise cutting of the material. The cutting power is 3.0 kW, and the L-Shaped Profile Making Machine's power supply is 415V, 50Hz, three-phase, ensuring smooth operation.

4)Electrical and Hydraulic System for L-Shaped Profile Making Machine

The L Angle Profile Roll Forming Machine is controlled by a PLC and servo motors. KINGREAL CEILING MACHINERY uses high-quality components to construct the L-Shaped Profile Making Machine's electrical system, which is equipped with a 10-inch touchscreen with multi-language support. Users simply enter system parameters (such as production speed and cutting length), and the L Angle Profile Roll Forming Machine will operate smoothly as required.

Complete Open Cell Ceiling System

1)L-Shaped Profile Making Machine

The L Angle Profile Roll Forming Machine plays a key role in the open cell ceiling system, producing Wall-mounted L-profiles tailored to the open cell ceiling's dimensions for installation. Its maximum production speed reaches 30m/min, significantly improving production efficiency.

2)Open Cell Ceiling Making Machine

Based on customer needs, KINGREAL CEILING MACHINERY offers open cell ceiling machines for U10/U15 grilyato ceilings for T15/T24 grid systems. These open cell ceiling machines can punch holes to meet customer needs, with adjustable punching distances available in eight sizes: 50/60/75/86/100/120/150/200mm. The standard perforation patterns produced are as follows:

Aperture diameter ø1.50mm, 22% free opening, 3mm pitch.

Aperture diameter ø2.50mm, 19% free opening, 5mm pitch.

In addition, the open cell ceiling machine's roller system allows for automatic width adjustment, allowing it to produce grilyato ceilings of varying sizes to meet diverse market demands.

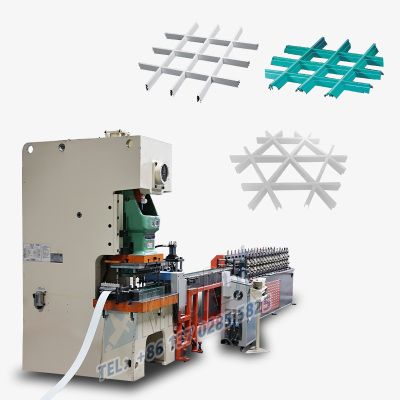

3)Sheet Metal Punching Machine

The sheet metal punching machine is capable of producing open cell ceiling connectors of various sizes. Primarily made from galvanized steel sheet, the sheet metal punching machine undergoes multiple, efficient process steps, including uncoiling, material straightening, servo feeding, punching, and finished product conveying, ensuring high-quality connectors that work seamlessly with open cell ceiling machines.

Grilyato Ceiling Installation

A complete open cell ceiling installation typically requires the following components:

1.Grilyato main profile 2400 mm long

2.Grilyato module (consists of bottom and top profiles with a length of 600 mm)

3.Grilyato longitudinal profile, length 600 mm

4.Wall-mounted L-profile, length 3000 mm

5.Grilyato suspension

6.Connecting piece for basic profiles with a length of 2400 mm

Open Cell Ceiling Installation Guide:

Ceiling Marking: Determine the horizontal plane for the suspended ceiling installation and mark the wall L-Profile. The distance between the suspended ceiling and the main ceiling should be at least 150mm. Installation of Wall L-Profiles: Wall L-Profiles are installed using dowels, with the dowels spaced 300-500 mm apart.

Marking and Installation of 2400 mm Main Profile Hanging Rods: The hanging rods are secured to the main ceiling using anchor bolts, spaced 800-1000 mm apart.

Frame Installation of 2400 mm Main Profiles and 600 mm Longitudinal Profiles: The main profiles are secured to the hanging rods and connected using connectors.

Assembling and Installation of the open cell ceiling: The main frame is secured to the hanging fixtures and connected using connectors.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)