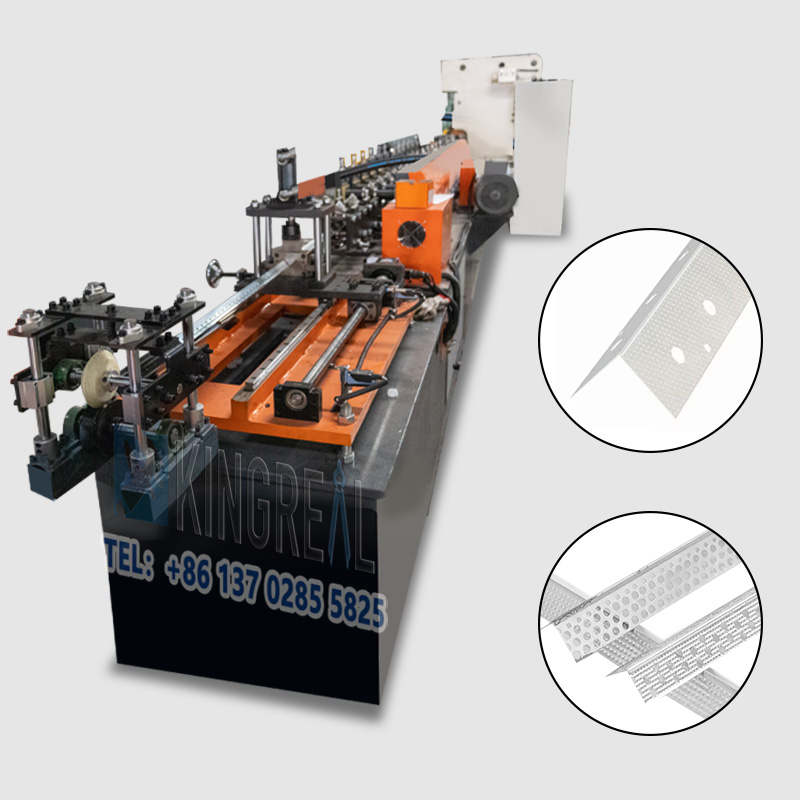

Perforated corner bead making machine in partition system

2025-08-23 17:00

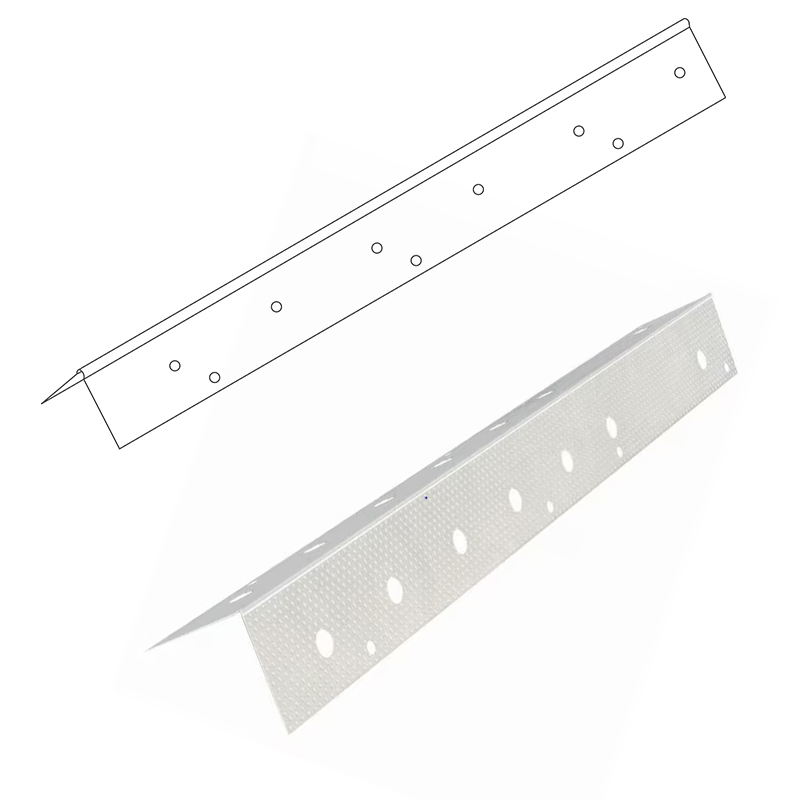

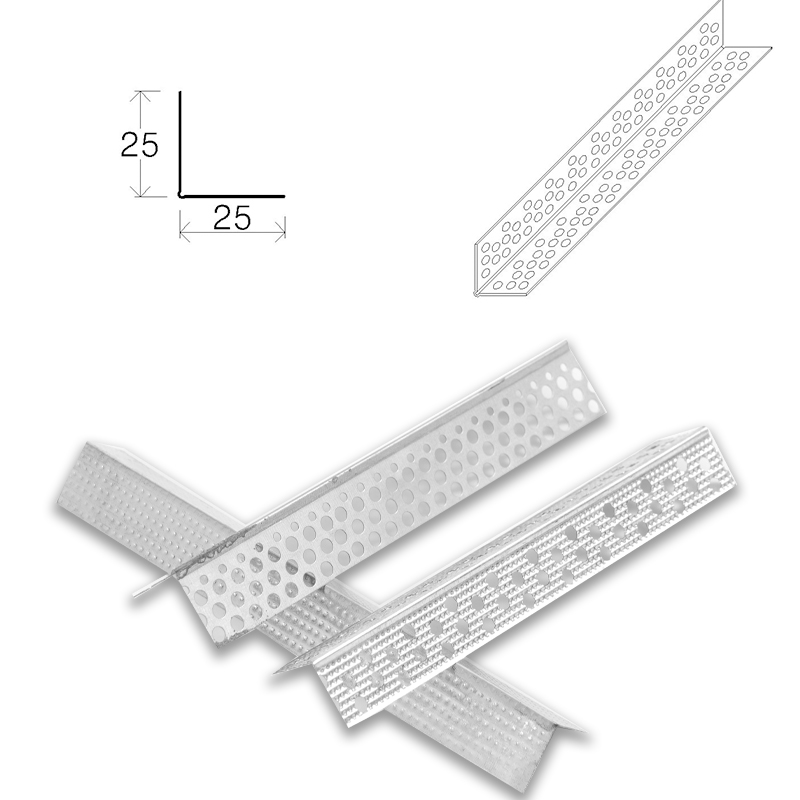

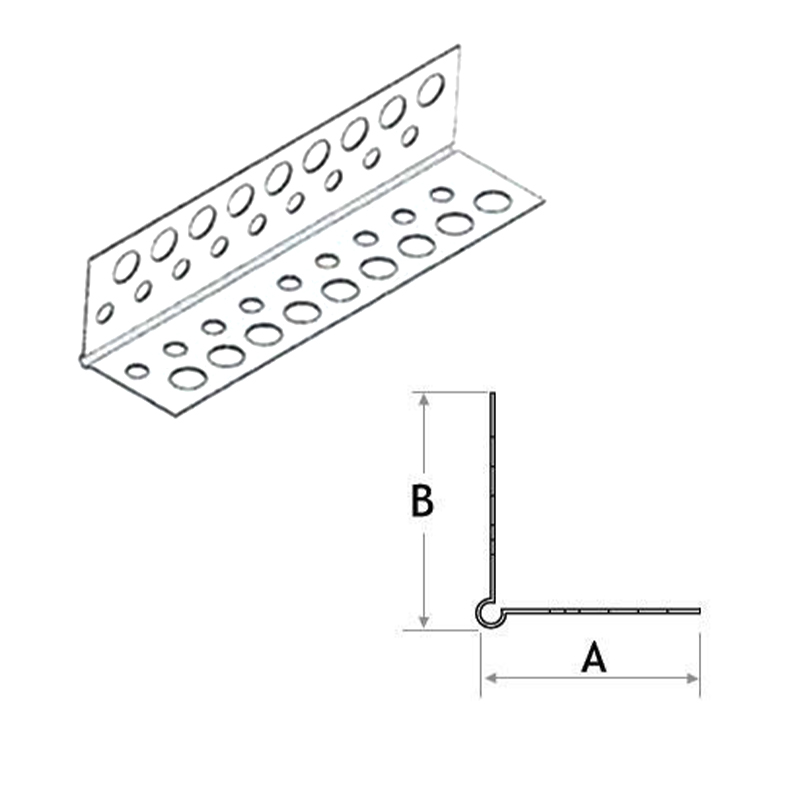

Perforated corner bead making machines can produce precise perforated corner bead of varying specifications. They play a key role in partition wall systems. KINGREAL CEILING MACHINERY drywall metal angle bead making machines can process a variety of metal materials, such as galvanized steel, stainless steel, and aluminum, with thicknesses ranging from 0.2 to 0.5 mm. KINGREAL CEILING MACHINERY perforated corner bead making machines can produce finished products in a variety of specifications, with standard lengths ranging from 2.4 to 3 meters and widths of 20 mm x 20 mm and 30 mm x 30 mm. Customization is also possible.

With the construction industry's continuous pursuit of material quality and construction efficiency, drywall metal angle bead making machines, due to their high efficiency and precision, have become the preferred equipment for many companies. This article will delve into the working principles, key components, application scenarios, and importance of perforated corner bead making machines in partition wall systems.

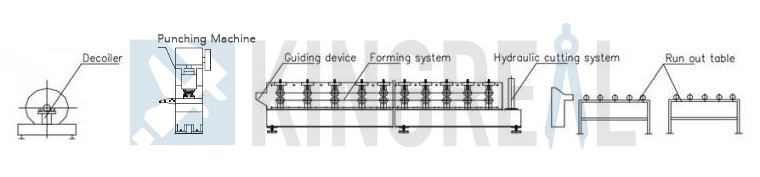

1/ Workflow of Drywall Metal Angle Bead Making Machine

Decoiler - Leveling Machine- Punching Machine - Roll Forming Machine - Shearing Station - Output Table - Auto Packing Machine (Optional)

2/ Key Components of Perforated Corner Bead Making Machine

1. 2-in-1decoiler & leveling machine for drywall metal angle bead making machine

KINGREAL CEILING MACHINERY typically equips its perforated corner bead making machines with a 2-in-1decoiler and leveling machine. This component is designed to efficiently and quickly unwind the metal coil and smooth out any wrinkles on the coil surface. This process not only lays a good foundation for subsequent punching but also significantly improves punching accuracy. This design reduces equipment footprint and improves production efficiency.

2. Punching machine for drywall metal angle bead making machine

The punching machine is the core component of the perforated corner bead making machine. KINGREAL CEILING MACHINERY punching machines deliver efficient punching performance and can customize punching dies according to customer drawings. For finished products requiring different hole shapes or diameters, simply changing dies allows for easy production of a wide range of products using a single drywall metal angle bead making machine. Furthermore, this punching machine features high safety features, enabling rapid shutdown in the event of an emergency, ensuring operator safety.

3. Roll forming machine for perforated corner bead making machine

The roll forming machine is crucial to the final shape of the perforated corner bead. KINGREAL CEILING MACHINERY equips the roll forming machine rollers with high-hardness wheels to ensure precise and stable forming. Furthermore, the unique arch design enhances perforated corner bead making machine stability during operation, extending the equipment's service life.

4. Cutting station for drywall metal angle bead making machine

Controlled by a PLC control panel, the cutting station accurately identifies the required length and cuts the corner bead. High cutting speed and burr-free finished surfaces ensure the quality and aesthetics of each corner bead. This process is particularly important in large-scale production, as it directly impacts the yield rate of the finished product.

5. Auto packaging machine for perforated corner bead making machine

To further improve production efficiency, KINGREAL CEILING MACHINERY can equip the drywall metal angle bead making machine with a packaging machine. The perforated corner bead are automatically transported to the packaging machine for bundling, packaging, and stacking. This automated process not only effectively improves production efficiency but also frees up manpower for a more streamlined production process.

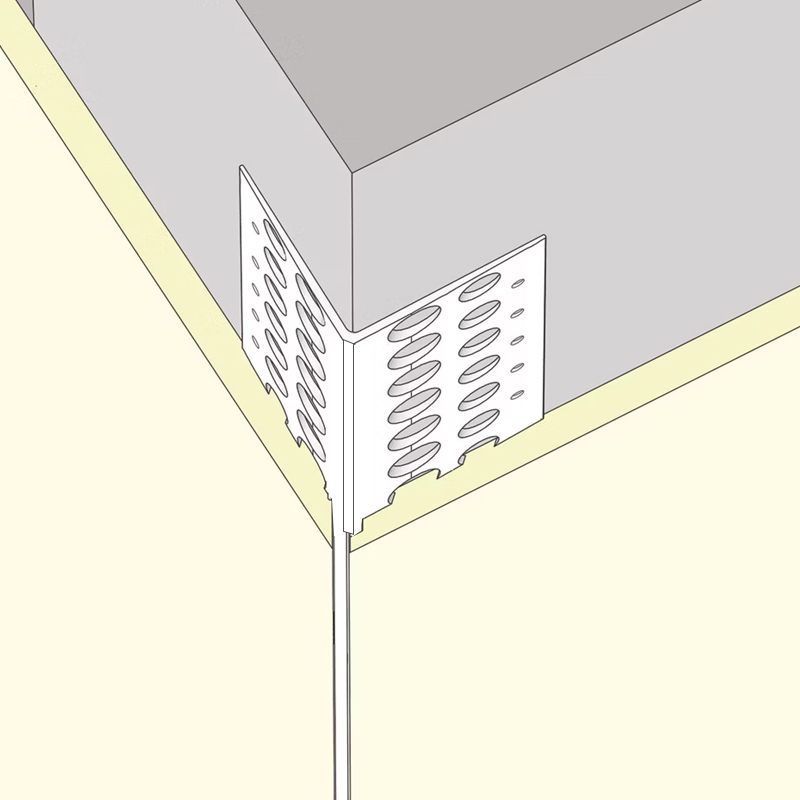

3/ Applications of Drywall Metal Angle Bead Making Machine

Whether in home renovation, office design, libraries, hotels, or restaurants, the perforated corner bead produced by the perforated corner bead making machine are an essential component of partition systems. In practice, designers and construction workers often select corner bead of appropriate specifications and materials based on the needs of each space to achieve the best decorative effect and functionality.

4/ Features of Corner Bead

1. Protection

Punched corner bead effectively protect the edges of walls and partitions, reducing damage caused by collisions and friction. Using corner beads makes wall corners less susceptible to external impacts, effectively extending the lifespan of the walls.

2. Aesthetics

Perforated corner beads can create smoother joints at corners, improving the overall decorative effect. They avoid the unsightly appearance of exposed wall surfaces and create a more harmonious and aesthetically pleasing overall space.

3. Improved Structural Strength

The installation of corner beads enhances the structural stability of partition walls, especially by providing additional support against external impacts. By increasing the rigidity and strength of the wall, perforated corner beads prevent deformation or damage from external forces.

4. Crack Prevention

Perforated corner beads can effectively prevent cracks at wall corners. Perforated corner beads enhance the strength of corners, maintain the integrity and aesthetics of the wall, and reduce subsequent maintenance costs.

Get the latest price? We'll respond as soon as possible(within 12 hours)