Drywall Wall Angle Profile Machine | 2025

2025-08-19 17:00

Drywall wall angle profile machines play an increasingly important role in the modern construction industry. Besides guaranteeing the quality and looks of the final product, this l-shaped profile making machine increases production efficiency.The range of use of drywall wall angle profile machines keeps growing as construction requirements vary, therefore rendering them an absolute necessity in construction.

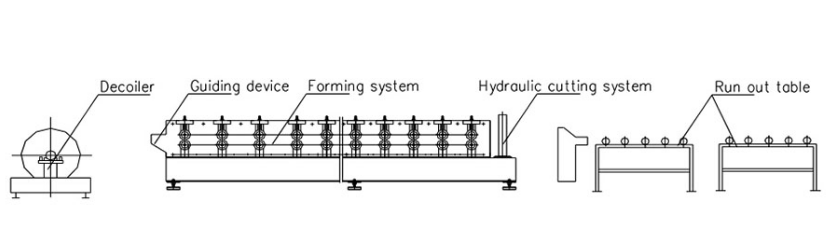

1/ Working Process of L-shaped Profile Making Machine

Hydraulic Decoiler--Main Roll Forming Machine--Fly Shearing System--Product Table

2/ Main Features of Drywall Wall Angle Profile Machine

1) Material processing for l-shaped profile making machine

The core of a drywall wall angle profile machine lies in its material processing capabilities. This gypsum ceiling channel making machine typically uses galvanized steel coils or strips, ensuring strength and durability during the forming process. Feeding the steel coils into a roll-forming process enables the gypsum wall angle making machine to efficiently produce the desired corners or corner beading.

2) Roll forming process of l-shaped profile making machine

The roll-forming process is a key step in a drywall wall angle profile machine. The metal coil is progressively shaped into a particular wall angle as it passes through the rollers and shaping parts of the l-shaped profile making machine.By guaranteeing accurate and uniform angles, this process guarantees that the final product perfectly fits between the wall and ceiling joints.Ensuring that every corner conforms to specifications and quality, the drywall wall angle profile machine precisely shapes galvanized steel into wall angle profiles.This accuracy is vital in building because even the tiniest departure can undermine the general appearance and structural integrity.

3) Wall angle profile forming for l-shaped profile making machine

Made for great production efficiency, this device runs at speeds of up to 120 m/min.Besides enhancing production capacity, this great speed drastically cuts down production cycle times, therefore helping developers to finish projects in less time.

4) High-speed operation for l-shaped profile making machine

To satisfy particular ceiling installation needs, the adjustable drywall wall angle profile machine can create wall angle profiles of different sizes, thicknesses, or forms.Builders may satisfy varied design needs and improve project flexibility thanks in part to this customizing feature.

5) Customization and precision engineering for l-shaped profile making machine

Although the initial expenditure on a gypsum wall angle making machine can be rather large, the longrun cost advantages are considerable.By lowering labor expenses, minimizing material waste, and speeding production times, construction businesses may greatly improve their profitability.

6) Integration into ceiling systems

The l-shaped profile making machine's formed drywall wall angle profiles are a crucial component in gypsum board ceiling installations. They not only provide structural support but also ensure a clean edge, resulting in a professional finish. This feature makes the l-shaped profile making machine an indispensable component of the entire suspended ceiling system.

3/ Advantages of Drywall Wall Angle Profile Machine

1) Cost-effective l-shaped profile making machine

Modern drywall wall angle profile machines may be programmed to produce a great range of wall angle types.This adaptability lets builders quickly meet the demands of several projects, whether employing conventional wall angles or unique custom forms.

2) Versatile drywall wall angle profile machine

Modern l-shaped profile making machines may be programmed to produce a great range of wall angle types.This adaptability lets builders quickly meet the demands of several projects, whether employing conventional wall angles or unique custom forms.

3) Sustainability for drywall wall angle profile machine

The effective performance of gypsum wall angle making machines turns into less material waste and a lower carbon footprint as the construction industry keeps moving toward sustainability.Accurate cutting and formability abilities help to preserve the environment by reducing material loss during the manufacturing process.

4/ Specifications of Drywall Wall Angle Profile Machine

| Product Name | L-shaped profile making machine |

Applicable Industries | Hotels, Clothing Stores, Building Materials Stores, Machinery Repair Shops, Manufacturing Plants, Food and Beverage Plants, Farms, Restaurants, Home Furnishings, Retail, Food Stores, Print Shops, Construction Engineering, Energy and Mining, Advertising Agencies |

| Material | Galvanized Steel |

| Conventional Dimensions | 25mm x 25mm x 3000mm |

| Core Components | PLC, Motor |

| Production Speed | 120m/min |

| Automation Level | Fully Automatic |

| Features | Fully Automatic, Adjustable Size |

| Control System | PLC |

| Automatic | Automatic Length and Quantity Control |

| Cutting | Non-Stop Cutting |

5/ Applications of Drywall Wall Angle Profile Machine

Drywall wall angle profile machines are widely used in the construction industry. Usually constructed of metal or plaster, l-shaped profiles offer a clean, polished edge where walls and ceilings meet or across several wall parts.This l-shaped profile making machine’s accuracy and efficiency guarantee structural integrity, prevent damage, and greatly improve the appearance of the finished goods.

Using a gypsum wall angle making machine enables construction workers to quickly create precise, durable, and aesthetically pleasing corners or beading. This automated process ensures consistency and precision that are difficult to achieve with traditional manual methods, significantly improving the quality and speed of construction projects.

The efficient performance of l-shaped profile making machines continues to enhance the quality of ceiling installations across a variety of residential, commercial, and industrial projects. Whether in large-scale commercial buildings, hotel renovations, or home renovations, gypsum wall angle making machines demonstrate their unique advantages.

As a vital piece of equipment in the modern construction industry, gypsum wall angle making machines are increasingly popular due to their superior performance and versatility. With the continuous advancement of construction technology, gypsum wall angle making machines will continue to play a vital role in improving construction efficiency, reducing costs, and achieving sustainable development. In the future, with the application of more innovative technologies, the market prospects for l-shaped profile making machines will be even broader, bringing more possibilities to the construction industry.

Tags: Gypsum Wall Angle Making Machine, Gypsum Ceiling Channel Making Machine, Gypsum Board Wall Angle Machine, Drywall Wall Angle Profile Machine, L-Shaped Profile Making Machine

Get the latest price? We'll respond as soon as possible(within 12 hours)