What is the function of a perforated metal making machine?

2025-08-15 17:00

A perforated metal making machine is a type of advanced metalworking equipment widely used in industrial manufacturing. Its primary function is to process various metal materials into products with specific hole shapes and diameters, providing efficient and precise solutions.

Metal perforating machines come in many kinds according on different techniques, including coil to coil perforation line, sheet metal perforating machine, and perforated metal ceiling panel machine.Meeting varied customer demands, these metal perforating machines can handle a great range of metallic materials including galvanized metal, iron, stainless steel, copper, and aluminum.

About Metal Perforating Machine

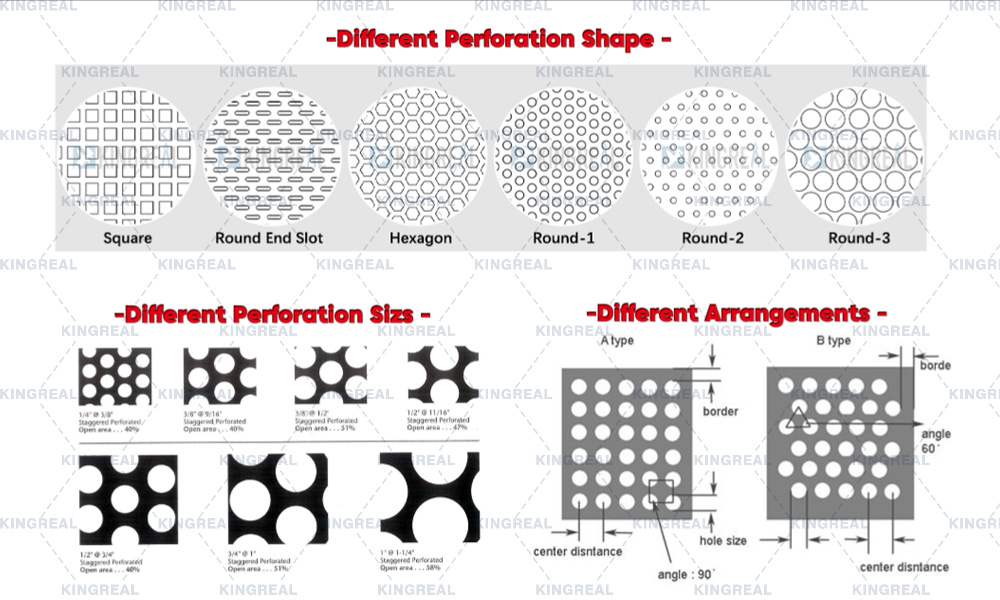

Perforated metal making machines are used to punch custom holes in various metal surfaces. The hole shape and diameter are freely selectable by the customer, and KINGREAL CEILING MACHINERY will manufacture customized punching dies. For example, round holes, long round holes, square holes, triangle holes, diamond holes, hexagonal holes, and crossed holes can all be created by KINGREAL CEILING MACHINERY metal perforating machines.

Perforated metal making machines can create precise holes in metal surfaces. Replacing traditional manual punching, metal perforating machines significantly improve production efficiency and enhance the precision of machine punching, ensuring consistent hole size and shape.

Diverse Functions of Perforated Metal Making Machine

Metal perforating machines have a wide range of functions. Below, KINGREAL CEILING MACHINERY will detail ten of their key functions.

1. Material Processing

One of the fundamental functions of a perforated metal making machine is to shape sheet metal into specific shapes and sizes. A metal perforating machine can give clients metal goods that satisfy their design needs by carefully punching holes.

Higher processing accuracy is obtained by this approach, therefore guaranteeing that every drilled hole fulfills consumer expectations. Moreover, it increases manufacturing efficiency.

2. Weight Reduction

Punching holes on a metallic surface with a perforated metal making machine will help to significantly lower the weight of metallic elements. Metal perforating machines cut material consumption while preserving structural integrity.

This is especially crucial in sectors like aerospace and car manufacture, where weight reduction not only raises fuel efficiency but also increases general performance.

3. Airflow

Metal perforating machine allows metal components to allow for free air or liquid movement in cooling and ventilation systems. Metal perforating machines assist to improve ventilation and maximize heat dissipation by piercing the metal surface.This is very important when designing ventilation ducts or cooling systems.

4. Aesthetic Design

Apart from its usefulness, perforated metal making machine gives decorative patterns that improve the look of a product.It can, for instance, be used to construct stairways and perforated screens, thereby bringing some creative flair to architectural and interior designs.

Based on their own tastes, consumers may choose from a range of hole patterns and patterns, therefore enabling metal perforating machine's flexibility to fulfill several design needs.

5. Acoustic Control

Perforated metal making machine also has a significant application in acoustics. By creating perforated ceilings and wall panels, it effectively absorbs sound and improves indoor acoustics.

This is particularly important in concert halls, conference rooms, and other venues requiring acoustic control, enhancing the overall listening experience.

6. Filtration

Metal perforating machine can also be used to create filters capable of separating solids and liquids. Through precise pore size design, perforated metal making machine can meet diverse filtration requirements and is widely used in water treatment, air filtration, and other fields. This functionality makes metal perforating machine a valuable environmental and hygienic tool.

7. Anti-slip Surface

Perforated metal making machines in some uses raise the friction of metal surfaces, therefore enhancing their anti-slip qualities.In places needing safety measures like stairs and platforms, where it effectively prevents slips and falls, therefore guaranteeing safety, this function is especially vital.

8. Electromagnetic Shielding

Metal perforating machine is increasingly common in electrical equipment. Through the appropriate placement of holes, it effectively prevents electromagnetic interference and ensures the proper functioning of equipment. This is crucial for electronics, communications, and other fields, improving product reliability and stability.

9. Heat Exchange

In heat exchangers, perforated metal making machine improves heat exchange efficiency. By perforating the metal surface, it increases the heat exchange area and optimizes heat transfer performance. This has important applications in air conditioning, refrigeration, and heating equipment.

10. Strengthening Structural Strength

At last, metal perforating machine can improve the stiffness and sturdiness of metal constructions by carefully placing holes.The design of perforating metal making machine takes into account the mechanical characteristics of the substance, therefore guaranteeing weight reduction without compromising structural stability and toughness.This attribute has made it quite useful in several sectors, including machinery manufacture and construction.

If you require a metal perforating machine, KINGREAL CEILING MACHINERY offers customized punching dies and perforated metal making machine solutions to meet your requirements for various hole shapes and diameters.

Whether you're processing metal coils with a thickness of 0.4-1.0mm or even thinner or thicker materials, KINGREAL CEILING MACHINERY engineers can tailor a satisfactory solution to your specific production needs. The future of metal perforating machines promises to be even brighter.

Get the latest price? We'll respond as soon as possible(within 12 hours)