What is a metal ceiling tile perforation line used for?

2025-08-13 17:00

Process metal coils such aluminum and iron, metal ceiling tile perforation lines create perforated ceiling panels with different apertures and specs. Common sizes include 300x300mm, 600x600mm, and 1200x600mm; common apertures are 1.8mm and 2.5mm.

Especially in public areas like school classrooms, offices, shopping centers, cinemas, and computer rooms—where demand for them is rather high—these perforated ceiling panels are crucial in current architecture and interior design.

1/ Function of Metal Ceiling Tile Perforation Line

Perforated metal ceiling making machine mostly turns metal coils into metal ceiling panels with particular apertures.

Perforated ceiling tiles are meant for both utility and beauty. Good sound insulation is a big benefit of perforated ceilings. Sound waves vibrate the air within the micro-pores when they hit the surface of a porous material.

The air within the micro-pores converts some of the sound energy into heat through frictional and viscous resistance as well as heat conduction, therefore providing sound absorption. Many public areas would find perforated ceilings to be the perfect solution because of this feature.

Metal ceiling panels made on a metal ceiling tile perforation line in school classrooms greatly lower noise and enable pupils to concentrate more. In offices, soundproofing improves employee productivity.

In cinemas and large shopping malls, ceiling panels produced on a metal ceiling tile perforation line create a more comfortable viewing and shopping environment. Furthermore, perforated ceiling panels are indispensable in places with extremely high acoustic requirements, such as computer rooms.

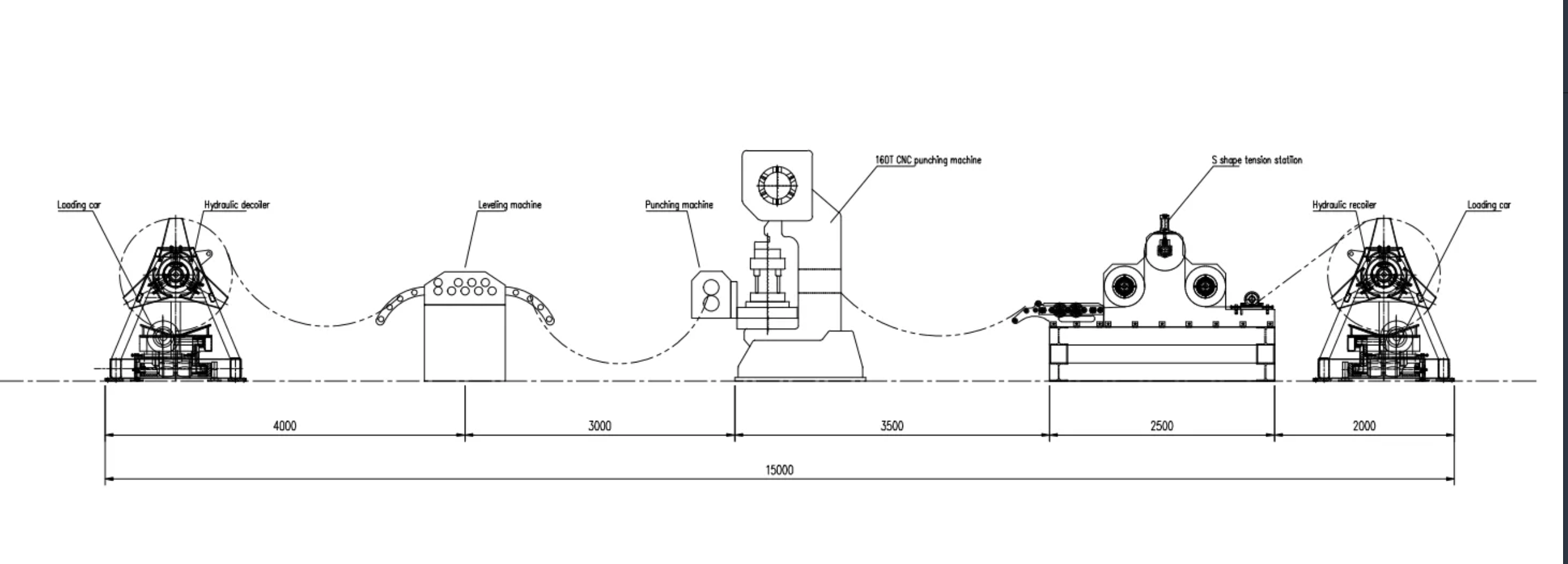

2/ Workflow of Perforated Metal Ceiling Making Machine

Decoiler - Precision Straightener - Punching Machine - Notching and Shearing Press - Second Precision Straightener - Bending Forming Press

3/ Advantages of Perforated Metal Ceiling Making Machine

1. Customized punching dies for metal ceiling tile perforation line

Customization of punching dies by KINGREAL CEILING MACHINERY is based on particular client needs.

Besides regular circular and square hole designs, KINGREAL CEILING MACHINERY experts can also meet particular customer demands including cross holes, diamond, hexagonal, oblong, and triangular holes.This tailored service guarantees the die is exactly aligned with the perforated metal ceiling making machine, therefore enabling high-precision punching.

2. Wide thickness range for metal ceiling tile perforation line

KINGREAL CEILING MACHINERY perforated metal ceiling making machines typically process metal coils with a thickness range of 0.4-1.0mm.

This thickness range meets the vast majority of market demands. If customers require thinner or thicker metal materials, KINGREAL CEILING MACHINERY welcomes further inquiries to explore metal ceiling tile perforation line manufacturing solutions.

3. Different punching machines for perforated metal ceiling making machine

KINGREAL CEILING MACHINERY offers punching machines of varying tonnages for our metal ceiling tile perforation making machines, tailored to customer production needs. Typically, perforated metal ceiling making machines are equipped with 120-ton or 125-ton punching machines, depending on the customer's desired production speed.

For larger widths and thicknesses, KINGREAL CEILING MACHINERY also offers 160-200-ton punching machines. The specific tonnage of the punching machine is determined by a calculation formula to ensure sufficient tonnage to punch the desired holes.

4/ Optional Configurations for Metal Ceiling Tile Perforation Line

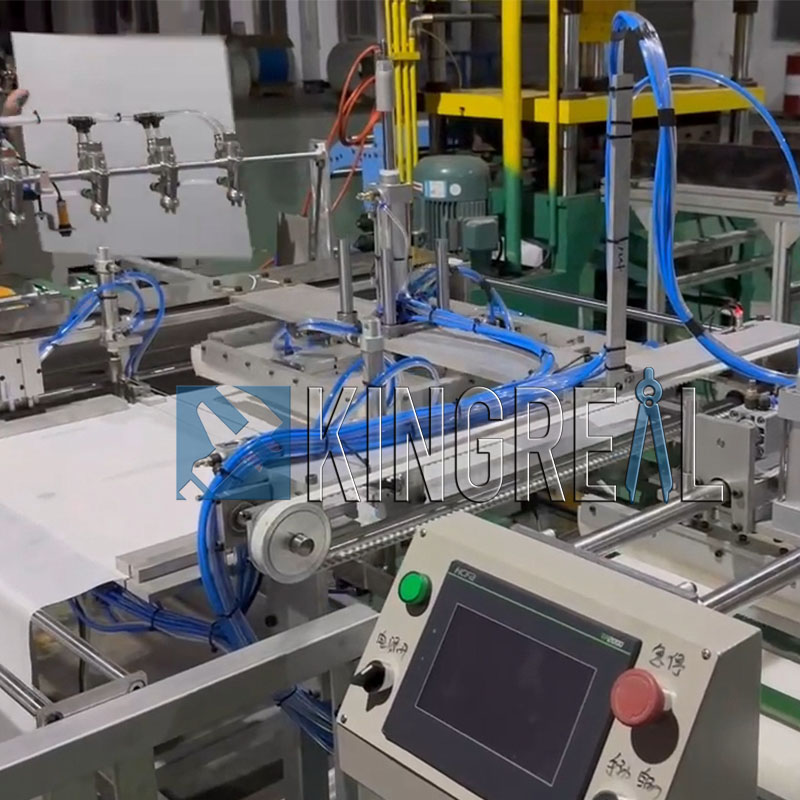

To further improve production efficiency, ensure fully automated perforated metal ceiling making machine operation, and enhance production accuracy, KINGREAL CEILING MACHINERY offers a variety of accessories for metal ceiling tile perforation making machines, providing a more intelligent perforated metal ceiling making machine manufacturing solution.

1. Feeding trolley for metal ceiling tile perforation line

The perforated metal ceiling making machine can be equipped with a feeding trolley, eliminating the need to manually transport large coils to the decoiler.

The feeding trolley automatically transports the coils, saving manpower and ensuring production speed. This configuration not only improves work efficiency but also reduces worker intensity.

2. Metal sheet cleaning machine for metal ceiling tile perforation line

Perforated ceiling panels produced by the perforated metal ceiling production line may retain oil or dust on the surface.

To address this issue, KINGREAL CEILING MACHINERY offers a high-speed metal sheet cleaning machine that efficiently cleans the ceiling surface and dries both sides.

This allows the finished product to be used or sold directly without any additional processing, greatly improving customer convenience.

3. Acoustical ceiling tile textile stick machine for metal ceiling tile perforation line

To further enhance the sound insulation of the perforated ceiling, the perforated metal ceiling making machine can be equipped with an acoustical ceiling tile textile stick machine.

This equipment applies non-woven fabric to metal ceiling panels, enhancing their sound absorption. Customers simply need to prepare rolls of ceiling material that meet specifications, and production can begin directly, eliminating unnecessary steps.

By carefully processing metal coils, the metal ceiling tile perforation line not only offers aesthetically pleasing ceiling materials but also satisfies the sound insulation and safety criteria of many public areas.

Through its customized services, great processing capabilities, and effective perforated metal ceiling making machine configuration, KINGREAL CEILING MACHINERY provides clients very competitive solutions for metal ceiling tile perforation line.

KINGREAL CEILING MACHINERY will keep concentrating on technical improvements and service enhancements to provide more value for clients as demand for metal ceiling tile perforation lines increases in the market.

Perforated metal ceiling making machines help to make the surroundings more pleasant everywhere, whether in schools, offices, major malls, or theaters.

Get the latest price? We'll respond as soon as possible(within 12 hours)