Cases: Sheet Metal Perforating Machine

Sheet metal perforating machine is KINGREAL CEILING MACHINERY featured machine. We have established close cooperative relations with customers in many countries, including the United States, United Arab Emirates, Egypt, India, Greece, Saudi Arabia, Brazil and Indonesia. This article will share some actual cases to show how KINGREAL CEILING MACHINERY metal sheet perforation machine meets the needs of different customers. If you want to know more about the sheet metal perforating machine or parameter data, please feel free to consult KINGREAL CEILING MACHINERY!

Case 1: Metal Sheet Perforation Machine in United Arab Emirates

Customer Background: The customer in the United Arab Emirates is a large metal processing company that mainly produces building materials. Their needs are mainly focused on the diversification of punching hole types and hole diameters, and they expect to achieve punching of multiple different hole types in one sheet metal perforating machine to improve production efficiency and market competitiveness. |  |

Metal Sheet Perforation Machine Manufacturing Solution:

KINGREAL CEILING MACHINERY provides customized sheet metal perforating machines. According to the United Arab Emirates Customers' specific drawings, KINGREAL CEILING MACHINERY designed a variety of punching dies for them. United Arab Emirates Customers only need to change the die to produce metal sheets with different hole types on the same metal sheet perforation machine. This flexible design not only saves United Arab Emirates customers' money, but also greatly reduces the time and space required for production, making the overall operation more efficient.

Metal Sheet Perforation Machine Manufacturing Results:

Through this metal sheet perforation machine, the United Arab Emirates customer successfully improved production efficiency by about 30% and obtained higher orders in the market. The United Arab Emirates customer was very satisfied with KINGREAL CEILING MACHINERY solution and believed that this sheet metal perforating machine would bring them greater benefits in the future.

United Arab Emirates Customer Feedback:

"We are very grateful for KINGREAL CEILING MACHINERY support. This metal sheet perforation machine not only improves our production efficiency, but also gives us an advantage in market competition."

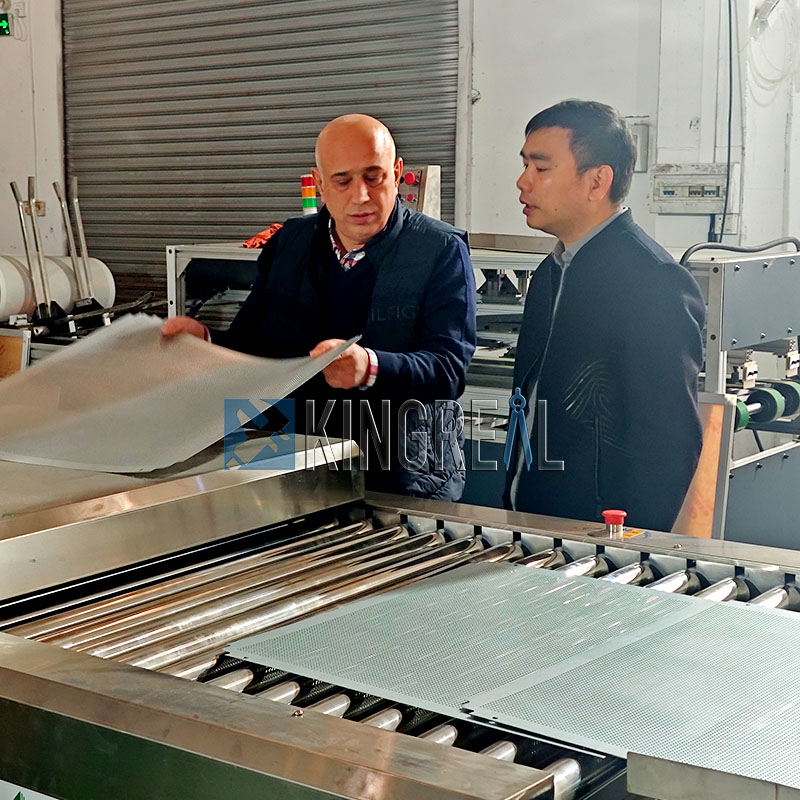

Case 2: Sheet Metal Perforating Machine in Greece

Customer Background: A metal processing company in Greece focuses on the construction industry. Greek customers need to punch out very small holes, mainly for the manufacture of metal wall panels. Since the common hole diameters on the market are usually 1.8mm and above, 1.0mm punching is difficult, and many manufacturers cannot meet this demand. |  |

Metal Sheet Perforation Machine Manufacturing Solution:

In response to the special needs of Greek customers, KINGREAL CEILING MACHINERY designed a punching die that can manufacture a minimum hole diameter of 1.0mm. KINGREAL CEILING MACHINERY sheet metal perforating machine has high-precision processing capabilities and can punch out the required hole diameter stably and efficiently. This solution enables Greek customers to successfully produce standard metal wall panels and meet the market demand for high-quality products.

Metal Sheet Perforation Machine Manufacturing Results:

By using KINGREAL CEILING MACHINERY sheet metal perforating machine, Greek customers have successfully improved the product qualification rate, received good market feedback, and quickly occupied the high-end market.

Greek Customer Feedback:

"KINGREAL CEILING MACHINERY sheet metal perforating machine has greatly improved our production capacity, especially in the small-diameter punching, we are very satisfied."

Case 3: Coil to Coil Perforation Line in Brazil

Customer Background: A manufacturing company in Brazil faced the problem of oil and stains on the surface of the sheet during the production process, resulting in substandard quality of the finished product. The Brazilian customer hopes to find a solution to ensure that the product meets the cleaning standard before leaving the factory. |  |

Coil to Coil Perforation Line Manufacturing Solution:

KINGREAL CEILING MACHINERY provides it with a coil to coil perforation line equipped with a metal sheet cleaning machine. After production, the metal perforated sheet is directly transported to the metal sheet cleaning machine for cleaning to ensure that there is no oil residue. The design of the coil to coil perforation line makes the entire production process smoother and reduces manual intervention.

Coil to Coil Perforation Line Manufacturing Results:

Brazilian customers reported that after adopting this coil to coil perforation line, the cleanliness and qualification rate of the product have been significantly improved, Brazilian customer satisfaction has also increased, and the order volume has increased by 25%.

Brazilian Customer feedback:

"The metal sheet cleaning machine design of the coil to coil perforation line is really our savior. The quality of the product has been greatly improved, and customers are more satisfied."

Case 4: Perforated Metal Ceiling Panel Machine in India

Customer Background: An Indian customer wants to produce 300x300mm clip-in and lay-in metal perforated ceiling tiles, and requires the metal ceiling board to have super high sound absorption function. This demand puts higher requirements on the flexibility and functionality of the perforated metal ceiling panel machine. |  |

Perforated Metal Ceiling Panel Machine Manufacturing Solution:

The perforated metal ceiling panel machine KINGREAL CEILING MACHINERY designed is equipped with an acoustical ceiling tile textile stick machine, which can produce two different types of metal perforated ceiling tiles on the same perforated metal ceiling panel machine by changing the mold. The flexibility of the perforated metal ceiling panel machine allows Indian customers to quickly switch production modes according to market demand, improving production efficiency.

Perforated Metal Ceiling Panel Machine Manufacturing Results:

Through this perforated metal ceiling panel machine, Indian customers not only successfully met market demand, but also received high recognition from Indian customers for the sound absorption effect of the metal perforated ceiling board, further enhancing brand influence.

Indian Customer Feedback:

"We are very satisfied with KINGREAL CEILING MACHINERY perforated metal ceiling panel machine. The flexible design has significantly improved our production capacity."

Case 5: Coil to Coil Perforation Line in Saudi Arabia

Customer Background: A manufacturing company from Saudi Arabia wanted to minimize manpower and increase production speed when producing motorcycle mufflers. The Saudi Arabian customer hoped to reduce labor costs through automated coil to coil perforation line. |  |

Coil to Coil Perforation Line Manufacturing Solution:

The coil to coil perforation line KINGREAL CEILING MACHINERY provides is equipped with a feeding trolley, which can automatically convey large rolls of metal coils to the decoiler for unwinding. In this way, there is no need for manual handling during the production process, which significantly improves production efficiency and safety.

Coil to Coil Perforation Line Manufacturing Results:

Saudi Arabian customers reported that the automated design greatly reduced labor costs, while the production speed increased by 50%, making the product more competitive in the market.

Saudi Arabian Customer Feedback:

"The degree of automation of this coil to coil perforation line exceeded our expectations, and the production efficiency was significantly improved. We are very satisfied."

Case 6: Sheet Metal Perforating Machine in Egypt

Customer Background: A customer in Egypt needs to produce bread trays and faces challenges in production efficiency and cutting accuracy. Egyptian customers hope to achieve efficient cutting and punching. |  |

Metal Sheet Perforation Machine Manufacturing Solution:

The sheet metal perforating machine KINGREAL CEILING MACHINERY provides is equipped with an intelligently operated cutting station, which can perform precise cutting according to the input parameters. The preset length of the Egyptian customer can be accurately achieved, ensuring the quality of each bread tray.

Metal Sheet Perforation Machine Manufacturing Results:

Through this sheet metal perforating machine, the Egyptian customer's production efficiency has increased by 40%, and the product qualification rate has also increased significantly. The Egyptian customer is very satisfied with the performance of the metal sheet perforation machine.

Egyptian Customer Feedback:

"KINGREAL CEILING MACHINERY sheet metal perforating machine not only improves our production efficiency, but also ensures high cutting accuracy. We are very grateful."

Case 7: Sheet Metal Perforating Machine in Indonesia

Customer Background: A customer in Indonesia involves two processes in the production process: metal sheet perforation machine and coil to coil perforation line. The Indonesian customer hopes to achieve two different production modes on the same sheet metal perforating machine. |  |

Metal Sheet Perforation Machine Manufacturing Solution:

KINGREAL CEILING MACHINERY designed a sheet metal perforating machine for them, equipped with a recoiler and a cutting station. When winding is required, the Indonesian customer can turn on the recoiler; when shearing is required, the cutting station can be turned on. This design not only improves production efficiency, but also provides Indonesian customers with greater flexibility.

Metal Sheet Perforation Machine Manufacturing Results:

Indonesian customers said that this flexible sheet metal perforating machine can better cope with market changes, production capacity has been significantly improved, and the order volume has also increased.

Indonesian Customer Feedback:

"We are very satisfied with the sheet metal perforating machine provided by KINGREAL CEILING MACHINERY. Its flexibility and efficiency perfectly meet our needs."

Through the above seven cases, we show how KINGREAL CEILING MACHINERY metal sheet perforation machine can provide flexible and efficient solutions to meet the needs of different countries and different customers. KINGREAL CEILING MACHINERY sheet metal perforating machine can not only meet the diverse hole type and hole diameter requirements, but also improve production efficiency and reduce labor costs through intelligent design.

If you have more requirements for the metal sheet perforation machine or want to know the specific technical parameters, please feel free to contact KINGREAL CEILING MACHINERY. KINGREAL CEILING MACHINERY looks forward to working with you to jointly open up a broader market!

Get the latest price? We'll respond as soon as possible(within 12 hours)