What is perforated metal machine?

2025-07-15 17:00

KINGREAL CEILING MACHINERY perforated metal machines usually punch out different hole types required by customers on the surface of large rolls of metal coils of different materials such as iron plates, stainless steel plates, aluminum plates, galvanized plates, nickel plates, etc., including round holes, long round holes, square holes, triangle holes, diamond holes, hexagonal holes, crossed holes, etc. Usually, the thickness of the coils processed by these steel perforated machines is within 0.4-1.0mm. The materials produced by the perforated metal machine will be processed later to finally produce perforated wall panels, stair treads, perforated ceilings, filters, silencers, bread trays, etc., which are widely used in the construction industry, chemical industry, industrial industry, etc. The steel perforated machine fully demonstrates its value in many industries. |  |

1/ Working Process of Perforated Metal Machine

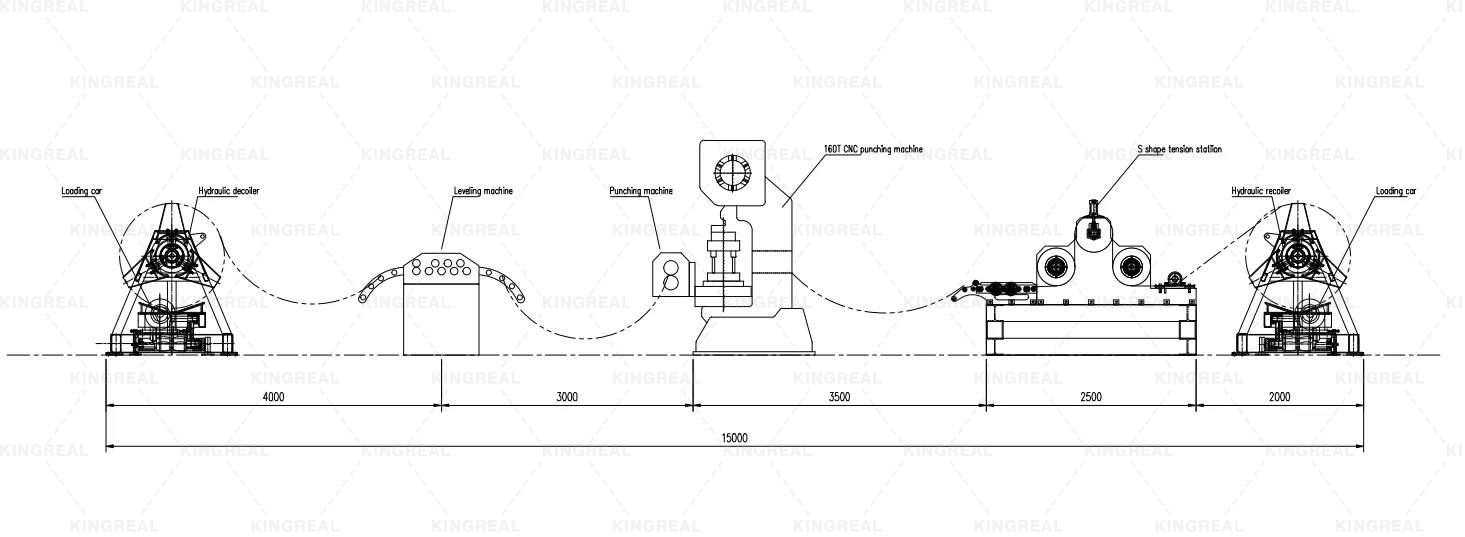

Hydraulic Decoiler -- Precision Leveling Machine -- Metal Punching Machine -- Cutting Station or Recoiler

2/Steel Perforated Machine Suitable Material Specification

Material: carbon steel (cold rolled), galvanized, aluminum, stainless steel...

Material thickness: 0.4-1mm

Hole type: round hole, long round hole, square hole, triangle hole, diamond hole, hexagonal hole, crossed hole...

Maximum punching distance: 20mm

Production method: Coil-to-coil / Coil-to-sheet / Sheet-to-sheet

3/Technical Data of Perforated Metal Machine

Nominal Pressure: 2000KN

Nominal Pressure Stroke: 2mm

Slide Stroke: 20mm

Max. Speed: 180SPM

Max. Die Height: 420mm

Die Height Adjustment: 50mm

Distance Between Uprights(FBxLR):500x1600mm

Bottom Size of Slide(FBxLR):750x1450mm

Main Motor Power:30KW

Aperture Accuracy ±0.1mm

4/Features of Steel Perforated Machine

The maximum stroke of the KINGREAL CEILING MACHINERY perforated metal machine can reach 180 SPM, which greatly improves production efficiency. This steel perforated machine is specially used for precise punching of metal coil surfaces and uses a punching die manufactured by a slow wire cutting process. The die material is made of high-strength CR12MOV or M2 steel to ensure its durability and stability. In addition, the punch needle uses M42 high-speed steel from Japan, which further improves the accuracy and efficiency of punching. In terms of safety, the KINGREAL CEILING MACHINERY perforated metal machine is equipped with a metal punching machine with a high safety factor and an emergency stop button to ensure that users can stop the machine in time in an emergency and ensure the safety of operators. |  |

Another major feature of KINGREAL CEILING MACHINERY perforated metal machine is that it can meet customers' demand for micro-apertures. At present, it can achieve excellent performance with a minimum aperture of 1mm. This steel perforated machine is very competitive in the market because there are great difficulties in the manufacture of punching dies and the configuration of perforated metal machines for micro-apertures. First, the manufacture of dies with tiny apertures requires higher technical standards and process levels to ensure the accuracy and wear resistance of the dies. Secondly, the steel perforated machine needs to have higher stability and precision during operation to prevent deviations during the punching process, which will affect product quality. |  |

With the growing market demand for perforated plates of different types and specifications, KINGREAL CEILING MACHINERY perforated metal machine has demonstrated its unique flexibility and adaptability. The steel perforated machine can flexibly adjust production parameters according to the specific requirements of customers to produce perforated plates of various specifications. By replacing different punching dies, KINGREAL CEILING MACHINERY perforated metal machine can realize the production of perforated metal plates with various hole types and apertures on the same production line. In addition, in order to better meet customers' diverse needs for production processes, KINGREAL CEILING MACHINERY has also designed three special steel perforated machines, including coil to coil perforation line, metal sheet perforated machine and metal ceiling tile perforation line. These perforated metal machines not only improve production efficiency, but also provide customers with more choices, ensuring that every customer can get high-quality products that meet their specific needs. |  |

5/Different Steel Perforated Machine Manufacturing Solutions

KINGREAL CEILING MACHINERY is good at providing customized perforated metal machine manufacturing solutions based on customers' actual production needs and drawings. Therefore, the parameters, performance and components of the steel perforated machines manufactured by KINGREAL CEILING MACHINERY are not exactly the same.

At the same time, KINGREAL CEILING MACHINERY can also sell other machines in combination to provide customers with complete perforated metal machine solutions. The following are the featured steel perforated machine manufacturing solutions:

The perforated metal machine is equipped with a recoiler and a cutting station.

In order to meet customers' needs for different production processes, KINGREAL CEILING MACHINERY can equip the steel perforated machine with a recoiler and a cutting station at the same time. When customers need to produce a specified length of punched sheet, they only need to turn on the shearing station to accurately cut it according to the customer's preset length. When customers need to reel the punched coils to accommodate long-distance transportation and subsequent secondary processing, they only need to turn on the recoiler. Note that these two machines will not operate at the same time. The design of this perforated metal machine saves customers the cost of purchasing multiple coil to coil perforation line, metal sheet perforated machines, and saves the manpower and cost of manually operating two machines.

The steel perforated machine is equipped with a feeding trolley.

In order to maximize production efficiency, the perforated metal machine with a feeding trolley only needs to place the heavy metal coils on the feeding trolley, and the feeding trolley will automatically transport them to the decoiler for unwinding. Improve production efficiency and ensure quality.

The steel perforated machine is equipped with a metal sheet cleaning machine.

During the punching process, oil stains and dust may appear on the surface of the punched coil. KINGREAL CEILING MACHINERY can equip the perforated metal machine with a metal sheet cleaning machine. This accessory will be connected to the steel perforated machine and will be transported to the metal sheet cleaning machine to start cleaning the surface after the punching is completed. This eliminates the need for customers to clean the punched sheet later. One perforated metal machine provides customers with punched sheets with high precision and high cleanliness.

The steel perforated machine is equipped with a unloading trolley.

When the coil to coil perforation line completes the recoiling of the punching coil, the unloading trolley equipped by KINGREAL CEILING MACHINERY will unload the punching coil from the reel, and then the unloading trolley will deliver the coil to the location specified by the customer. Increase the speed and reduce the probability of safety hazards in production.

Steel perforated machine with metal ceiling machine.

When the metal ceiling tile perforation line and metal ceiling machine are equipped together, different types of perforated ceiling tiles can be produced, such as 300x300mm, 600x600mm, 600x1200mm and other sizes and clip in ceiling tile, lay in ceiling tile, tegular ceiling tile and other types of ceiling tiles.

Equip the perforated metal machine with metal punching machines of different tonnages.

The metal punching machine is an important part of the steel perforated machine. It is used to punch holes on the surface of metal coils. The tonnage of the metal punching machine usually depends on the production requirements of the customer, such as the hole type, material width, material type, and material thickness. KINGREAL CEILING MACHINERY can usually provide 120 tons/125 tons/160 tons/200 tons punching machines for the perforated metal machine. Generally, large-tonnage punching machines are used for production needs with large width, large thickness, and many holes. Sufficient tonnage is required to punch out the holes required by customers. KINGREAL CEILING MACHINERY has a calculation formula and gives suggestions based on KINGREAL CEILING MACHINERY engineers' many years of experience in manufacturing perforated metal machines.

6/Full Support During Your Steel Perforated Machine Purchase Journey

Factory visit.

KINGREAL CEILING MACHINERY welcomes customers from all over the world to visit the KINGREAL CEILING MACHINERY factory to visit the perforated metal machine in person. Here, KINGREAL CEILING MACHINERY staff will accompany customers throughout the process and give customers the most professional answers to questions related to steel perforated machines. Customers can see and input the actual production parameters of various types of perforated metal machines with different parameters and performances to operate the machine, and measure the punching plates to test the accuracy.

Personalized steel perforated machine solutions.

KINGREAL CEILING MACHINERY staff will provide customers with personalized perforated metal machine manufacturing solutions based on the drawings provided by customers and dig deep into customers' production needs. Among them, they will design multiple sets of punching dies for customers based on customers' drawings, design steel perforated machines that meet customers' production efficiency, and equip the perforated metal machines with more components that improve production efficiency or safety performance according to customers' special needs.

Machine manufacturing.

KINGREAL CEILING MACHINERY has its own factory to manufacture steel perforated machines, so it can guarantee quality and product delivery. During the perforated metal machine manufacturing stage, KINGREAL CEILING MACHINERY has a professional inspection team that goes to the workshop to inspect the machine parts produced and follow up on the steel perforated machine manufacturing to ensure that the perforated metal machine manufacturing can be completed before the promised date.

Machine inspection.

After the steel perforated machine is manufactured, KINGREAL CEILING MACHINERY will install and test the perforated metal machine in the factory, mainly testing whether the steel perforated machine can meet customer requirements for smooth operation, efficient production, adaptability to different production parameters, punching accuracy, etc. Only qualified perforated metal machines will be sent to the customer's factory.

Machine installation.

When the steel perforated machine is sent to the customer's factory, KINGREAL CEILING MACHINERY will send engineers to install the perforated metal machine and help customers debug the parameters for the machine so that the customer can use it directly.

Machine operation training.

KINGREAL CEILING MACHINERY engineers will also provide steel perforated machine operation training to workers to ensure that every worker is proficient in machine operation.

Get the latest price? We'll respond as soon as possible(within 12 hours)