Ceiling T Bar Machine to Dominica

Earlier this month, KINGREAL CEILING MACHINERY delivered a high-precision ceiling t bar machine to a customer's factory in the Dominican Republic. KINGREAL CEILING MACHINERY is dedicated to offering dependable and effective ceiling t grid machine and services for customers.

This ceiling t grid machine features integrated punching and shearing capabilities, capable of achieving a high production speed of 30 m/min. The Dominican customer's large-scale production requires the ceiling t bar machine to operate for extended periods, sometimes for over ten hours a day. Therefore, KINGREAL CEILING MACHINERY engineers specially equipped the ceiling t grid machine with a hydraulic oil cooler. This design effectively reduces the risk of overheating, which can lead to reduced efficiency and ceiling t bar machine damage during extended operation, ensuring smooth and continuous production for the Dominican customer.

Packing and Shipping Process of Ceiling T Bar Machine

KINGREAL CEILING MACHINERY instituted a strict packaging and shipping procedure before the ceiling t grid machine was prepared for delivery to guarantee that every ceiling t bar machine arrived safely and precisely at its recipient. immediately. The stages in this process are many:

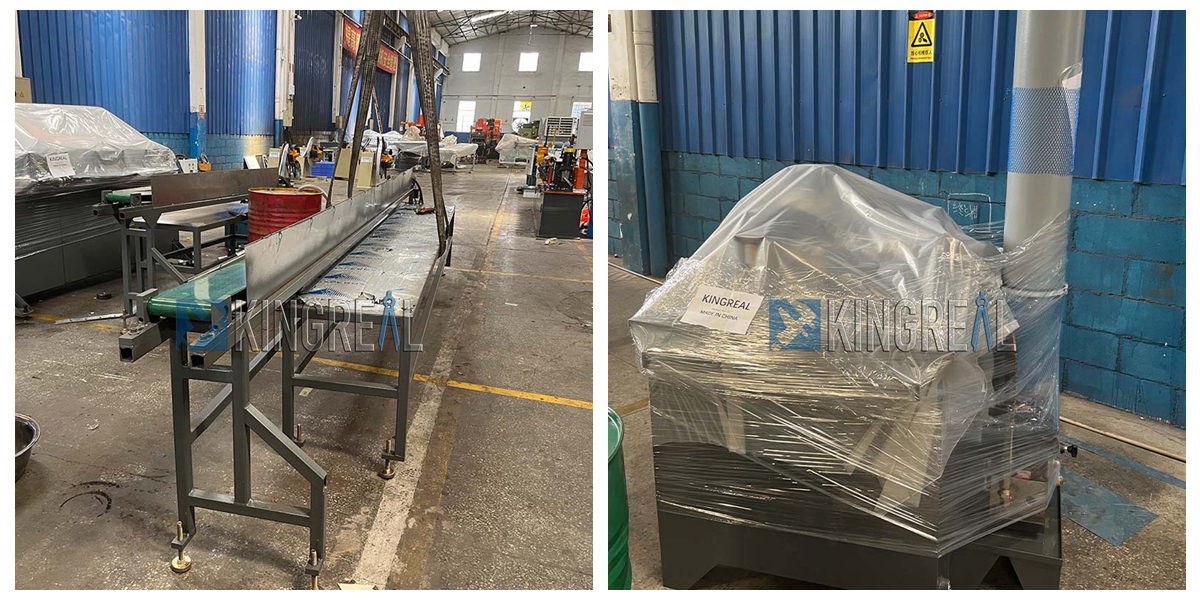

1) Verifying Ceiling T Bar Machine Components

The first step in packaging and shipping is a thorough verification of all ceiling t grid machine components. KINGREAL CEILING MACHINERY staff carefully inspect each component against the checklist, including the hydraulic decoiler, main roll forming machine, punching and shearing station, product table, electrical system, hydraulic system, and punching die. They particularly carefully check the brand of the low-voltage components within the electrical cabinet to ensure that all components are consistent with the ceiling t bar machine's manufacturing plan agreed upon with the Dominican customer. Accuracy in this process is directly related to the ceiling t grid machine's proper operation and the Dominican customer's production efficiency.

2) Precision Packaging of Ceiling T Grid Machine

After completing the inspection, KINGREAL CEILING MACHINERY staff begin the precise packaging of the ceiling t bar machine's components. This procedure includes scientific and logical handling suited to the unique features of every component, not just simple packing. Plastic film or wooden crates are used to contain both fragile or delicate parts and stronger ones. Furthermore, relevant papers like the ceiling t grid machine's operating and maintenance manuals are offered to guarantee the Dominican customer may operate the machine with ease and swiftly start manufacturing.

3) Ceiling T Bar Machine Loading onto the Truck

Using tools like a crane, KINGREAL CEILING MACHINERY personnel meticulously carried the ceiling t grid machine components to the rear of the truck once they had been packaged. To guarantee safety during transit, KINGREAL CEILING MACHINERY employees firmly fastened the parts with ropes to avoid harm from braking or other unexpected events.

4) Ceiling T Bar Machine Loading onto the Ship

After the truck gently transported the ceiling t grid machine parts to the port, KINGREAL CEILING MACHINERY employees loaded them onto the ship for delivery to the customer's manufacturing facility in the Dominican Republic. KINGREAL CEILING MACHINERY observed every element to guarantee the safety and stability of the ceiling t bar machine in transit during this process. KINGREAL CEILING MACHINERY personnel gave the Dominican customer real-time progress feedback throughout the whole packaging and shipping procedure via pictures and videos, therefore guaranteeing they had a better fostering consumer trust and clear knowledge of the most recent ceiling t grid machine advances.

Dominican customer' trust in KINGREAL CEILING MACHINERY keeps increasing together with the arrival of the ceiling t grid machine. KINGREAL CEILING MACHINERY will keep refining its machinery design and manufacturing methods going forward so that every ceiling t bar machine satisfies customer demands. KINGREAL CEILING MACHINERY will keep refining its technology and create more high-performance and effective gear as demand for effective production ceiling t grid machine rises worldwide. By constant work, KINGREAL CEILING MACHINERY hopes it can find its place in the future of machine building.

Get the latest price? We'll respond as soon as possible(within 12 hours)