Morocco Project: Steel Perforated Machine

In the metalworking industry, steel perforated machine installation and commissioning are critical steps to ensure smooth production. KINGREAL CEILING MACHINERY recently successfully completed a perforated metal machine project in Morocco. After several steps, including plan confirmation, steel perforated machine manufacturing, and commissioning, the perforated metal machine was shipped to Morocco in June. This month, KINGREAL CEILING MACHINERY engineer visited the customer's factory to perform installation and commissioning.

01/Pre-Departure Preparations

Before departing for Morocco for the steel perforated machine installation, KINGREAL CEILING MACHINERY engineer undertook thorough preparations. Along with the plan for the perforated metal machine and the required installation tools, they also brought a thorough steel perforated machine maintenance guide and instruction manual. Ensuring they could rapidly react to several events during the installation process, these papers included the operating methods, troubleshooting, and regular maintenance measures for the perforated metal machine. Moreover, the KINGREAL CEILING MACHINERY engineer made sure that all tools and accessories were well stocked for a flawless operation by bearing in mind the possible difficulties of international transportation. Factory installation at the customer in Morocco.

Read more: Coil to coil perforation line

02/Steel Perforated Machine Inspection

Upon arrival at the customer's factory in Morocco, KINGREAL CEILING MACHINERY engineer immediately began working with the local workers. They first took out a checklist and individually verified the completeness of each perforated metal machine component. Using forklifts and other auxiliary equipment, KINGREAL CEILING MACHINERY engineer placed the steel perforated machine after verifying all components were in good form and untouched. Preparing for installation, perforated metal machine elements based on the layout of the Moroccan customer’s factory. This step is very important as any errors or damage might impact later perforated metal machine setup and commissioning.

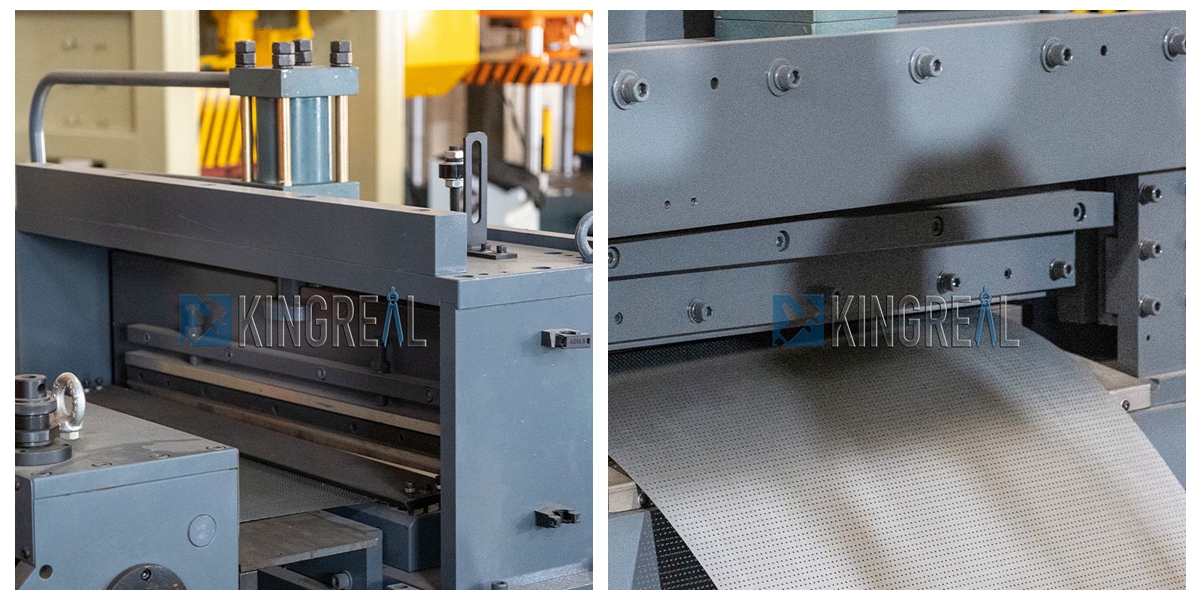

03/Steel Perforated Machine Installation

Perforated metal machine installation is the core of the entire project. KINGREAL CEILING MACHINERY engineer worked closely with the Moroccan workers to install each component of the steel perforated machine, including the decoiler, leveling machine, metal punching machine, cutting machine, and recoiler. Based on the Moroccan customer's requirements, KINGREAL CEILING MACHINERY equipped the perforated metal machine with a cutting machine and recoiler, meeting both punching and winding and punching and shearing processes. During the installation process, KINGREAL CEILING MACHINERY engineer also paid special attention to the installation of the punching dies, ensuring they were positioned accurately to ensure smooth subsequent production.

Read more: Sheet metal perforation machine

04/Steel Perforated Machine Trial Run

After installation, KINGREAL CEILING MACHINERY engineer started a test run of the perforated metal machine after installation, feeding the metal coils and performing a power-on test. KINGREAL CEILING MACHINERY engineer adjusted criteria like preset cutting length and production speed throughout this process to guarantee the steel perforated machine could create high-precision finished goods under several manufacturing environments. Ensuring the perforated metal machine satisfies the Moroccan customer and serves as a thorough confirmation of the installation process for the steel perforated machine depends on this step.

Read more: Metal ceiling tile perforation line

05/Perforated Metal Machine Commissioning

After the trial run, KINGREAL CEILING MACHINERY engineers conducted a detailed analysis of the steel perforated machine's operation and carried out targeted commissioning. The purpose of commissioning was to further optimize the perforated metal machine's performance and ensure it fully met the production requirements of the Moroccan customer. Through meticulous adjustments, KINGREAL CEILING MACHINERY engineer ensured that the steel perforated machine operated stably under all production parameters, achieving optimal results.

06/Perforated Metal Machine Operation Training

After confirming that the steel perforated machine could meet the daily production requirements of the Moroccan customer, KINGREAL CEILING MACHINERY engineer provided comprehensive machine operation training to the Moroccan workers. The training covered how to start and shut down the perforated metal machine, how to set and modify parameters on the control panel, and how to change punching dies to produce finished products with different hole shapes and diameters. Through this training, the Moroccan workers not only mastered basic operating skills but also became able to flexibly respond to various situations in actual production.

KINGREAL CEILING MACHINERY engineer also emphasized the importance of routine steel perforated machine maintenance. To guarantee the long-term, stable operation of the steel perforated machine, they described the perforated metal machine maintenance procedure comprising frequent inspections, cleaning, and lubrication. KINGREAL CEILING MACHINERY hopes that the Moroccan employees will be able to keep the perforated metal machine running perfectly and so prolong its life with these directions.

Read more: Steel perforated machine

This after-sales service was not only a technical support experience, but also forged a deep bond between KINGREAL CEILING MACHINERY, its Moroccan customers, and its workers. Throughout the steel perforated machine installation and training process, KINGREAL CEILING MACHINERY engineers and Moroccan workers assisted each other, fostering mutual understanding and trust. The Moroccan customer expressed satisfaction with the comprehensive service provided by KINGREAL CEILING MACHINERY.

In a subsequent video conference, the Moroccan customer even expressed a desire to return to China for a face-to-face meeting with the KINGREAL CEILING MACHINERY team, particularly regarding the purchase of additional machines. Both parties expressed interest in further deepening their cooperation. This perforated metal machine project in Morocco showcased KINGREAL CEILING MACHINERY expertise in steel perforated machine installation and customer service. Through thorough preparation, meticulous installation, and comprehensive training, KINGREAL CEILING MACHINERY not only successfully provided its customers with high-quality perforated metal machine, but also established a trustworthy image in their hearts. KINGREAL CEILING MACHINERY looks forward to further cooperation with its Moroccan customers and thanks them for their trust and support.

Get the latest price? We'll respond as soon as possible(within 12 hours)