Case: Coil to Coil Perforation Line in Morocco

In the global manufacturing industry, KINGREAL CEILING MACHINERY is committed to providing customers with efficient and high-quality metal processing equipment. KINGREAL CEILING MACHINERY coil to coil perforation line has been highly praised by customers in many countries, including Greece, the United Arab Emirates, Turkey, Saudi Arabia and India. Today, KINGREAL CEILING MACHINERY will focus on sharing a case of a coil to coil perforated making machine that has been successfully operated in a Moroccan customer's factory to demonstrate KINGREAL CEILING MACHINERY continued efforts and achievements in the international market. |  |

Project Background

The Moroccan customer is a company specializing in metal processing. They hope to improve production efficiency and product quality by introducing advanced coil to coil perforation lines. In many communications with KINGREAL CEILING MACHINERY, the Moroccan customer clarified the specific needs of the coil to coil perforation line, including efficient production capacity, flexible aperture setting and convenient subsequent processing capabilities.

To this end, KINGREAL CEILING MACHINERY customized a coil to coil perforated making machine for Moroccan customers to meet their needs for diversified finished products. The design of this coil to coil perforation line fully considers the actual use of customers to ensure stable operation under high load.

Features of Coil to Coil Perforated Making Machine

Rewinding function

This coil to coil perforation line is equipped with a recoiler, which can effectively rewind the perforated metal coils for subsequent long-distance transportation. Moroccan customers can use this coil to coil perforation line to process a variety of products, including perforated baffle ceilings, perforated screens, perforated filter elements and perforated bread trays, which greatly meets the diverse finished product needs of Moroccan customers.

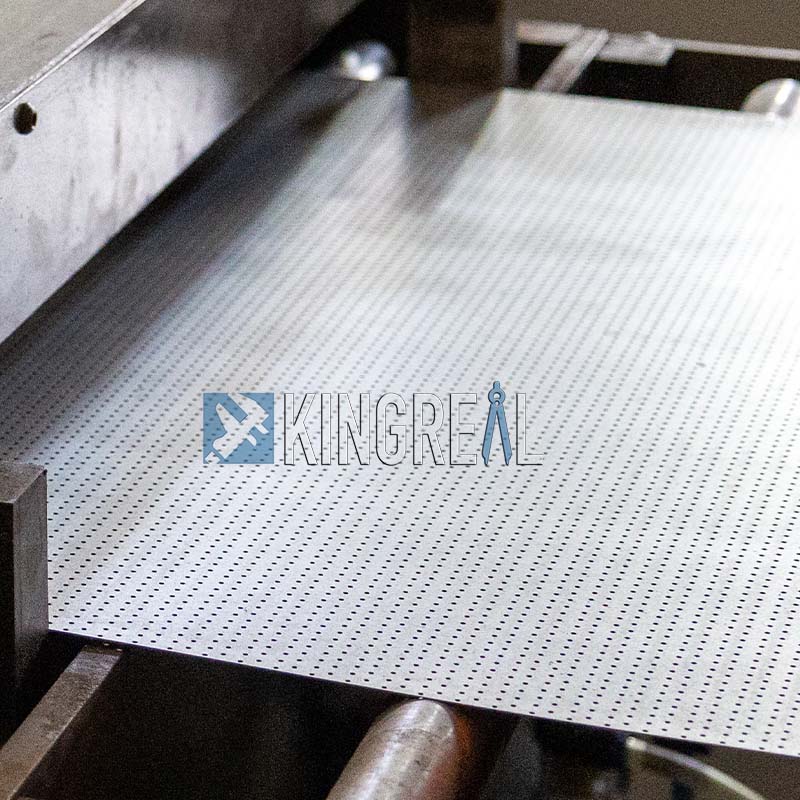

Flexible aperture setting

This coil to coil perforated making machine can produce holes of different apertures. It is worth mentioning that this coil to coil perforated making machine can punch out micro holes as small as 1.5mm! By replacing the punching die, Moroccan customers can easily adjust the production specifications. KINGREAL CEILING MACHINERY designs and manufactures punching dies according to the drawings provided by customers to ensure the accuracy and consistency of punching to meet the specific needs of Moroccan customers.

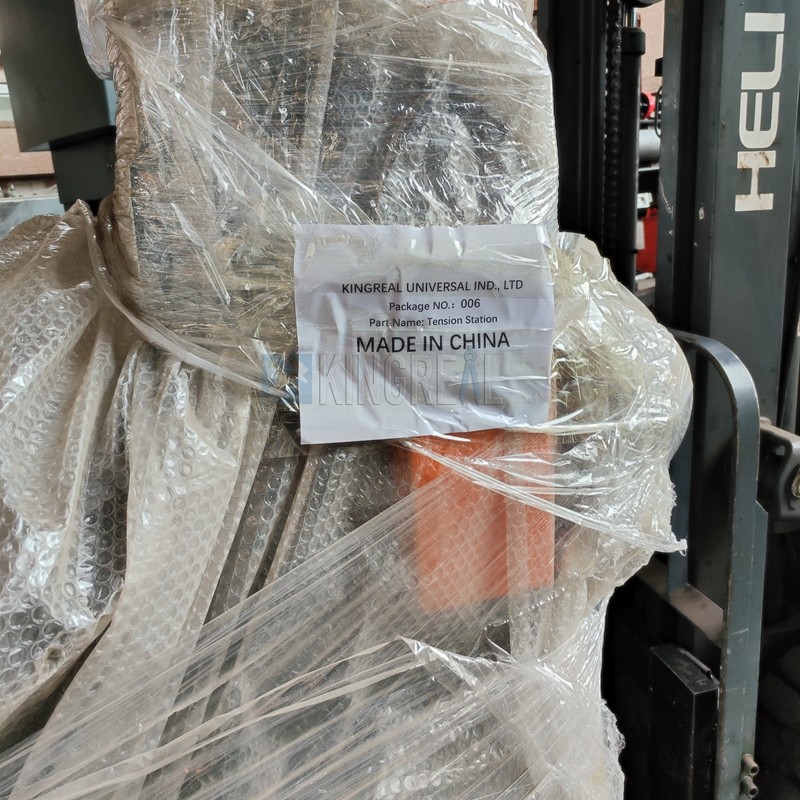

Packing & Delivery Service

Installation and Commissioning of Coil to Coil Perforation Line

After the coil to coil perforated making machine arrived in Morocco, KINGREAL CEILING MACHINERY engineering team immediately went to the customer's factory for installation and commissioning. In order to ensure that the Moroccan workers could master the operation of the coil to coil perforation line, the engineers conducted detailed training.

1. Installation process

On site, KINGREAL CEILING MACHINERY engineers first conducted a comprehensive inspection of the coil to coil perforated making machine to ensure that all parts were intact. Then, the team began to install the coil to coil perforation line:

Equipment positioning: According to the layout of the factory, the engineers and the customer's staff jointly confirmed the best location of the coil to coil perforated making machine to ensure the efficiency of the production process.

Electrical connection: During the installation process, the engineer explained in detail the precautions for electrical connection to ensure that the coil to coil perforation line can operate normally.

Commissioning and operation: After the coil to coil perforated making machine was installed, the engineer conducted preliminary commissioning to ensure that all functions were operating normally.

2. Training and interaction

Next to the coil to coil perforation line, the engineers conducted detailed operation training for the Moroccan workers. During the training, the workers actively asked questions according to their own questions, and the engineers patiently answered every question to ensure that they could fully understand the operation and maintenance of the coil to coil perforated making machine.

Mold replacement teaching: KINGREAL CEILING MACHINERY engineers particularly emphasized the mold replacement process, because this is the key to ensuring production flexibility and efficiency. They demonstrated step by step how to change the punching die safely and quickly, and involved the Moroccan workers in the process to deepen their understanding.

Troubleshooting: KINGREAL CEILING MACHINERY engineers also introduced common faults and their troubleshooting methods to ensure that workers can deal with problems in a timely manner in daily production and reduce downtime.

Customer Feedback on Coil to Coil Perforation Line

After several days of installation and training, the coil to coil perforated making machine was finally put into production smoothly. Moroccan customers expressed high satisfaction with KINGREAL CEILING MACHINERY coil to coil perforation line and services. They especially mentioned that the high-efficiency performance and flexible aperture settings of the coil to coil perforation line greatly improved their production capacity and were able to respond quickly to market demand.

At a feedback meeting, the Moroccan customer representative excitedly said: "This coil to coil perforated making machine not only meets our production needs, but more importantly, it makes our production process more efficient. KINGREAL CEILING MACHINERY is very much looking forward to more such coil to coil perforation line and services in future cooperation."

Through the successful cooperation with Moroccan customers, KINGREAL CEILING MACHINERY has once again demonstrated its professional capabilities in the field of coil to coil perforated making machines. KINGREAL CEILING MACHINERY goal is to provide customers with efficient and flexible production solutions to help them stand out in the highly competitive market.

If you are interested in KINGREAL CEILING MACHINERY coil to coil perforation line or want to know more parameter information, please feel free to contact KINGREAL CEILING MACHINERY. KINGREAL CEILING MACHINERY looks forward to working with you to explore a broader market and provide the best solution for your production needs!

Get the latest price? We'll respond as soon as possible(within 12 hours)