KINGRAL CEILING MACHINERY Open Cell Ceiling Machine

2025-05-10 17:00

KINGRAL CEILING MACHINERY is a machine manufacturer with more than 20 years of experience, focusing on the production and manufacturing of open cell ceiling machines. With rich industry experience and advanced technology, KINGRAL CEILING MACHINERY grilyato ceiling machines have been running smoothly in customer factories in many countries around the world, significantly improving production efficiency. KINGRAL CEILING MACHINERYopen cell ceiling machines have been widely used in countries such as Russia, Vietnam, Turkey, India and Saudi Arabia, and have won unanimous praise from customers. This article will focus on KINGRAL CEILING MACHINERY grilyato ceiling machines, showing its unique advantages in design, function and service.

KINGRAL CEILING MACHINERY Open Cell Ceiling Machine vs. Other Suppliers’

Production efficiency

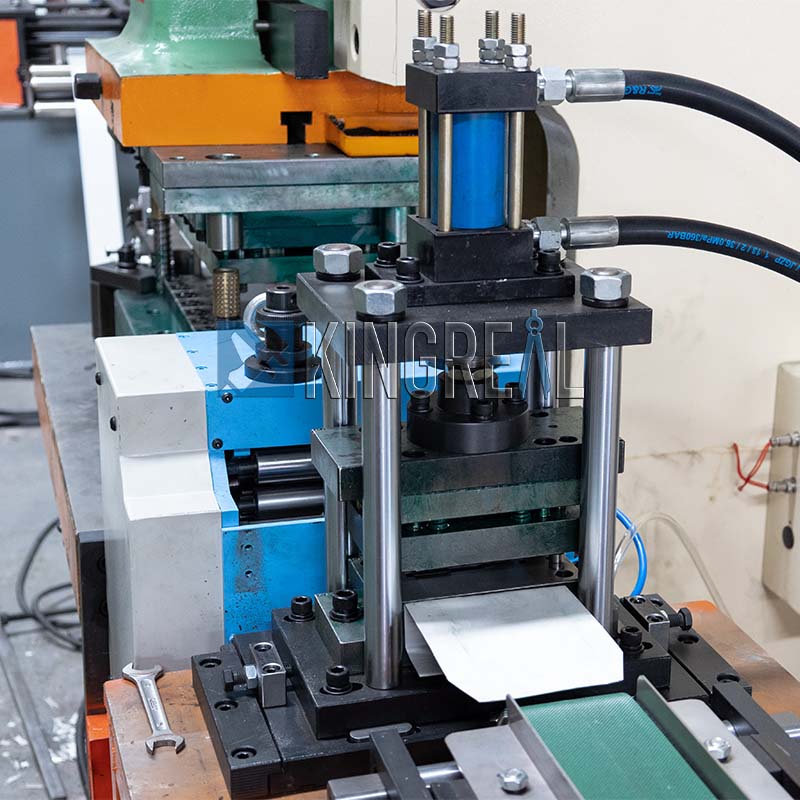

In order to maximize the production efficiency of customers, KINGRAL CEILING MACHINERY engineers have comprehensively upgraded the open cell ceiling machine. From the previous 16-ton punch press to a 63-ton punch press, this change has significantly improved the production capacity of the grilyato ceiling machine. After the upgrade, the open cell ceiling machine can punch a row of holes at a time instead of just one hole. This innovative design not only improves production efficiency, but also greatly reduces the production cycle, allowing customers to respond to market demand at a faster speed.

Open cell ceilings of different specifications

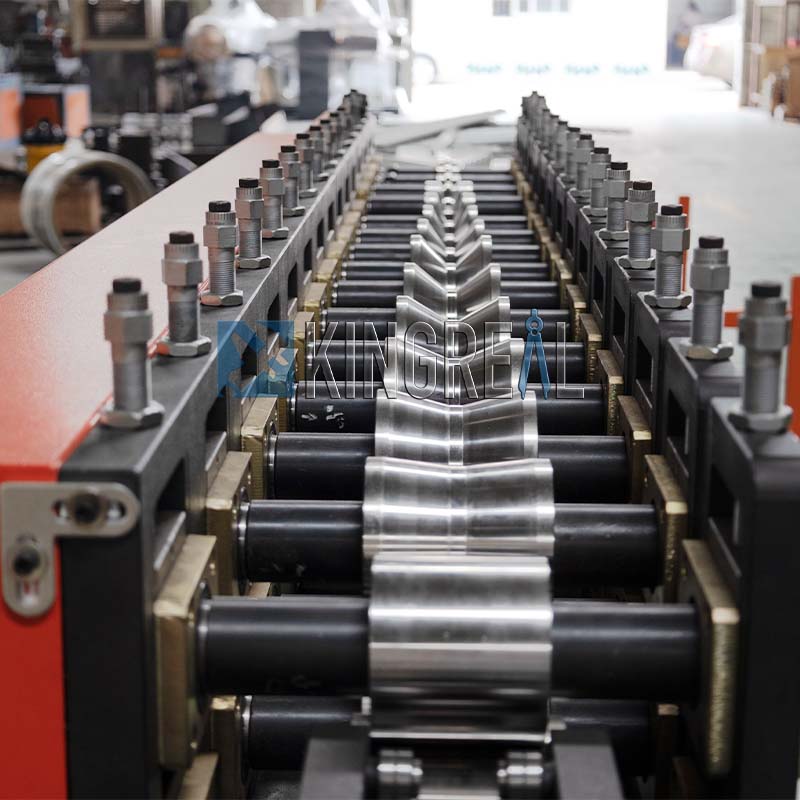

KINGRAL CEILING MACHINERY grilyato ceiling machine can produce open cell ceilings of various sizes, including 25x25mm, 30x30mm, 38x38mm, 50x50mm and 65x65mm, etc. The open cell ceiling machine is equipped with a roll forming machine roller that can automatically adjust the width and narrowness. Users can easily achieve the production of grilyato ceilings of different sizes with simple operations. This flexibility enables KINGRAL CEILING MACHINERY grilyato ceiling machine to meet the diverse needs of different customers and adapt to various market changes.

Flexibility

KINGRAL CEILING MACHINERY open cell ceiling machine excels in material compatibility, and can be compatible with two metal raw materials: 0.25-0.4mm iron and 0.3-0.4mm aluminum. The grilyato ceiling machine’s fastest production speed can reach 30m/min, and users can flexibly adjust the speed according to actual production conditions. This flexibility enables customers to optimize the configuration according to different production tasks, improving the overall efficiency of the open cell ceiling machine.

Machine selection

KINGRAL CEILING MACHINERY has designed a variety of open cell ceiling machines for different customers' production needs, including C-type grilyato ceiling machines, U-type grilyato ceiling machines, pyramid grilyato ceiling machines, standard open cell ceiling machines, high-end open cell ceiling machines, and open cell ceiling machines with protective shield. In addition, KINGRAL CEILING MACHINERY has also designed customized grilyato ceiling machines for Vietnamese customers to meet their special finished product requirements and parameter requirements. Through these customized solutions, KINGRAL CEILING MACHINERY ensures that every customer can get open cell ceiling machine that fully meets their production needs.

High precision

In terms of machine manufacturing, KINGRAL CEILING MACHINERY always adheres to the principle of excellence. Whether it is the overall structure of the grilyato ceiling machine or the tiny screws, KINGRAL CEILING MACHINERY requires it to perfectly match the relevant components. The roller of the open cell ceiling machine is made of CR12Mov material with a hardness of HRC58-60 degrees, ensuring efficient forming and cutting accuracy. In addition, the blade of the shearing station is also made of high-hardness material, which further enhances the cutting ability of the grilyato ceiling machine. Through strict quality control and trial open cell ceiling machine testing, KINGRAL CEILING MACHINERY ensures the high precision and high quality of the finished product.

After-sales service

KINGRAL CEILING MACHINERY also performs well in after-sales service. KINGRAL CEILING MACHINERY professional engineers will go to the customer's factory for offline installation and provide grilyato ceiling machine operation training to ensure that workers can operate the open cell ceiling machine correctly. Through this thoughtful service, KINGRAL CEILING MACHINERY not only helps customers get started quickly, but also provides strong support for their subsequent production.

Product Display

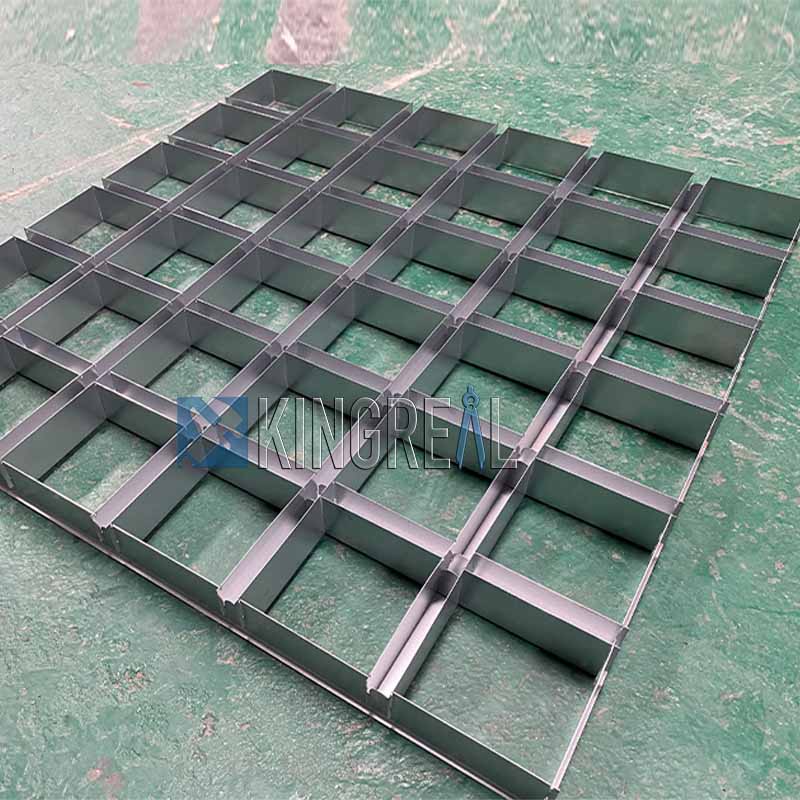

KINGRAL CEILING MACHINERY grilyato ceiling machine with its excellent production capacity and exquisite manufacturing process, can produce burr-free and highly consistent open cell ceilings. These finished products are widely used in various open spaces such as subway station passages, airports, high-speed rail stations, offices, shopping malls, clubs and restaurants with their excellent appearance and practicality. These application scenarios not only reflect the industrial value of the open cell ceiling machine, but also demonstrate its important role in modern architecture and design.

1. High-quality open cell ceilings

The grilyato ceilings produced by the KINGRAL CEILING MACHINERY grilyato ceiling machine have the characteristics of burr-free, ensuring the perfect visual and tactile experience of each product. This high-quality finished product not only improves the installation efficiency when installed, but also reduces the trouble of later maintenance. Because the edges of the open cell ceiling are smooth, it is not easy to cause scratches or damage, ensuring safety and comfort during use.

2. Consistency and beauty

Another major advantage of the KINGRAL CEILING MACHINERY open cell ceiling machine is the consistency of its products. This means that the size, shape and appearance of each open cell ceiling can be highly consistent and meet strict industrial standards. This consistency enables the grilyato ceiling to be seamlessly connected when used on a large scale, improving the overall aesthetics. For example, in places with high traffic such as subway station passages and airports, the uniformity of the open cell ceilings can significantly enhance the visual effect of the space, making it look more modern and professional.

3. Application scenarios

-Subway station passages

-Airports and high-speed rail stations

-Offices and shopping malls

-Clubs and restaurants

Get the latest price? We'll respond as soon as possible(within 12 hours)