Sheet Metal Punching Machine

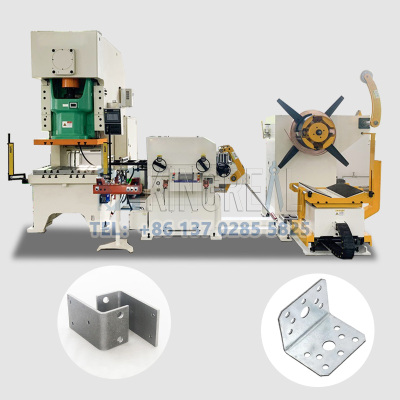

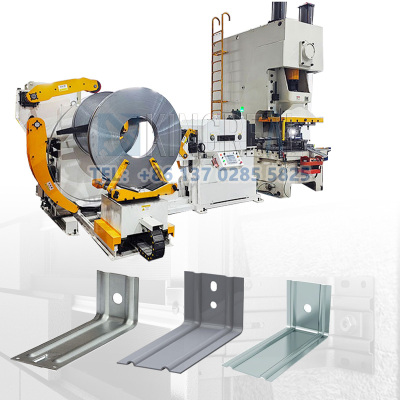

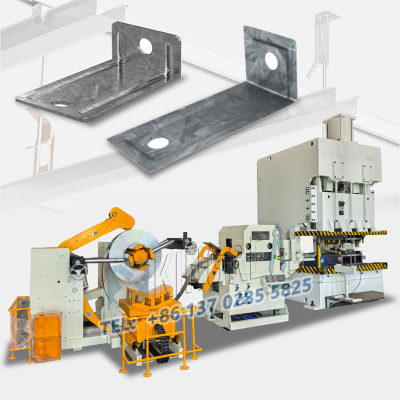

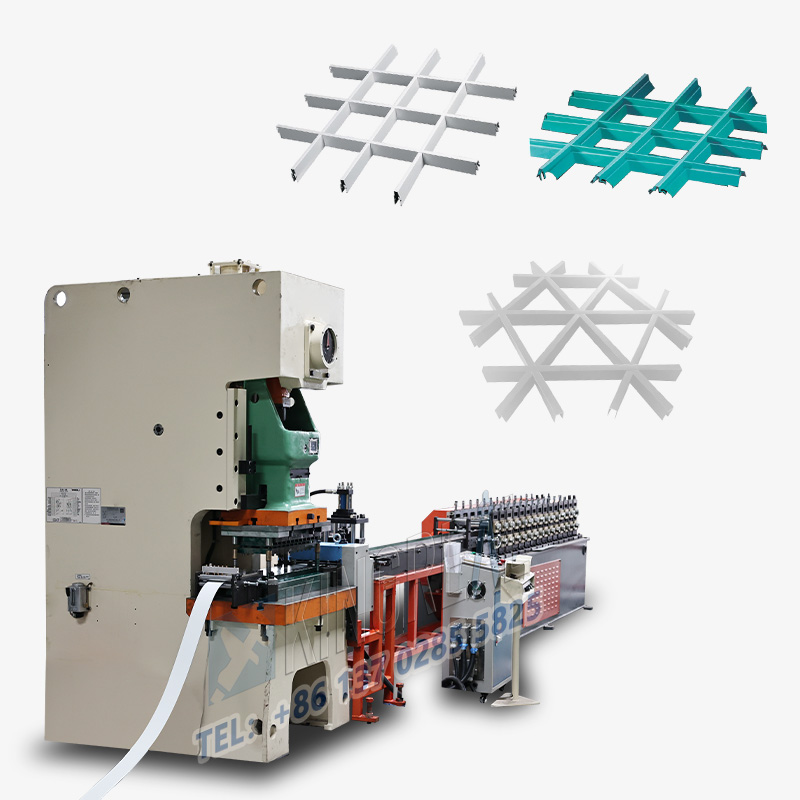

KINGREAL CEILING MACHINERY sheet metal punching machine is specifically designed for producing open cell ceiling connectors, critical components for securing open cell ceilings to building structures. Primarily using galvanized steel sheets, the metal part stamping machine incorporates a series of efficient process steps, including unwinding, material straightening, servo feeding, punching, and finished product delivery. This sheet metal punching machine works well with an open cell ceiling machine.

- KINGREAL CEILING MACHINERY

Details

Video About Sheet Metal Punching Machine

Description of Sheet Metal Punching Machine

KINGREAL CEILING MACHINERY sheet metal punching machine is specifically designed for producing open cell ceiling connectors, critical components for securing open cell ceilings to building structures. Primarily using galvanized steel sheets, the metal part stamping machine incorporates a series of efficient process steps, including unwinding, material straightening, servo feeding, punching, and finished product delivery. This sheet metal punching machine works well with an open cell ceiling machine.

The fully automated operation of this sheet metal punching machine not only improves production efficiency but also ensures high precision and stability. Its minimal operator requirements make it suitable for a wide range of businesses. Through optimized design and efficient production processes, KINGREAL CEILING MACHINERY provides customers with an ideal solution for seamless open cell ceiling installation, ensuring quality and efficiency.

Complete Open Cell Ceiling Solution

This metal part stamping line, combined with an open cell ceiling machine, forms a complete grilyato ceiling system. Open cell ceilings of varying sizes produced by the KINGREAL CEILING MACHINERY open cell ceiling machine are then joined with support profile connectors produced by the metal part stamping machine to smoothly complete the open cell ceiling installation. This system solution not only simplifies the procurement process and reduces the need for customers to navigate multiple suppliers, but also ensures a perfect match between the sheet metal punching machine and the open cell ceiling machine, improving overall production efficiency and construction quality. With the KINGREAL CEILING MACHINERY metal part stamping machine, customers not only receive high-quality products but also enjoy convenient service and support. The efficiency and reliability of this sheet metal punching machine will provide strong support for customers' open cell ceiling installation projects.

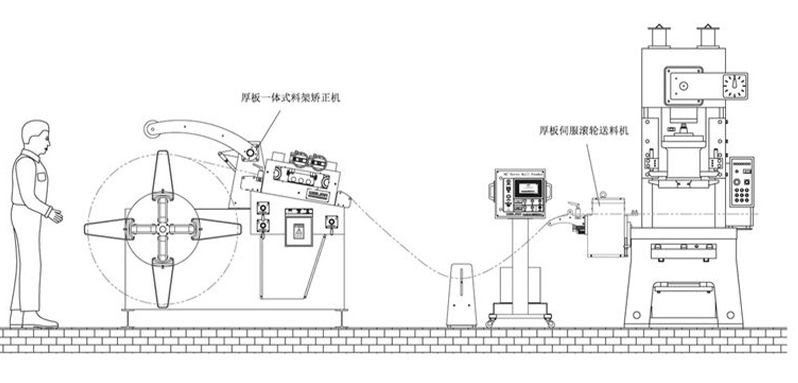

Working Process of Sheet Metal Punching Machine

Raw Material Uncoil → Material Straightening →Servo Feeder → Auto Punching → Products Output

Components of Sheet Metal Punching Machine

| List | Name | Type | Qty | Description |

| 1 | Combine Decoiler & Straightener | Single Head | 1 Unit | Passive Decoil, hydraulic Expanding, Auto leveling |

| 2 | Servo Feeder | NC roll Feeder | 1 Unit | High precision servo roller feeder |

| 3 | 25ton Automatic Punch press | 1 Unit | Yangli Brand, high precision 25 tons capacity press | |

| 4 | Electrical Control system | 1 set |

Parameters of Sheet Metal Punching Machine

| Nominal force | 250kN |

Nominal Stroke | 2.5mm |

| Slide Stroke | 60mm |

| Strokes per minute | 80-100 |

| Maximum mold height | 180mm |

| Mold height adjustment | 70mm |

| Slide center to machine | 210mm |

| Worktable size (FB*LR) | 400x600mm |

| Blanking hole size | Φ120mm |

| Worktable thickness | 70mm |

Body worktable hole size | 180x180mm |

Slide bottom size | 210x250mm |

Mold handle hole size | Φ40x70mm |

| Distance between columns | 330mm |

| Motor | 3KW |

Metal Part Stamping Machine Component Details

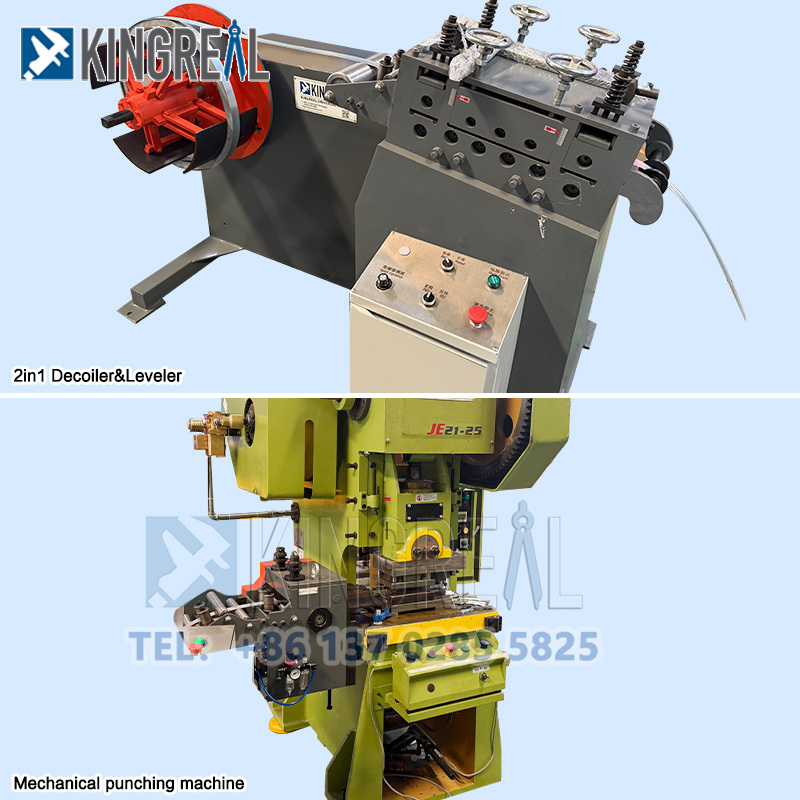

1) 2-in-1 decoiler and leveler for sheet metal punching machine The 2-in-1 decoiler and leveler equipped with the metal part stamping machine features a hydraulic tensioning frame with a load capacity of up to 2,000 kg and manual feeding and tensioning functions. The decoiler can handle material with an inner diameter of 460 mm to 520 mm, with a maximum outer diameter of less than 1,400 mm. The leveler utilizes a horizontal roller design, effectively straightening coils with a thickness range of 0.5 to 3.2 mm. The straightening rollers are made of GCr15, tempered, finely ground, chrome-plated, and polished to ensure high durability and precision. KINGREAL CEILING MACHINERY has equipped the sheet metal punching machine with a 2-in-1 decoiler and leveler, which takes up minimal space and significantly improves production efficiency. |  |

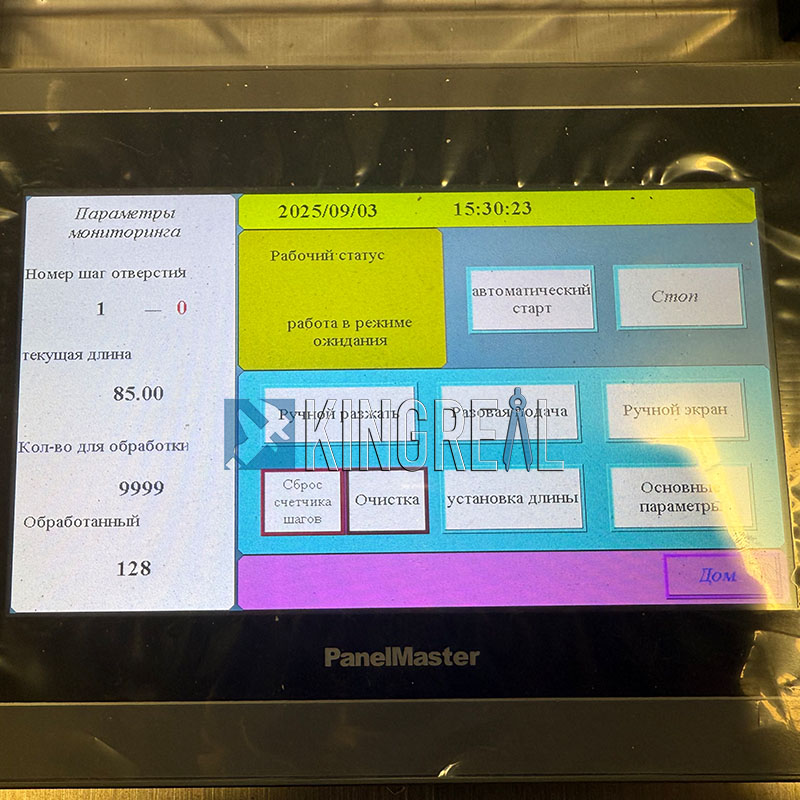

2) Servo feeder for metal part stamping machine The servo feeder for the metal part stamping line utilizes a Yaskawa servo motor, a Panasonic PLC, and a 7-inch color display, enabling efficient and effective coil feeding. This advanced feeding system ensures accurate feeding every time, making the entire production process smoother and more efficient. |  |

3) Punch press for sheet metal punching machine KINGREAL CEILING MACHINERY 25-ton punch press for the metal part stamping machine boasts powerful punching capacity and can be used with progressive dies to precisely punch and cut coils. The press can reach 80-100SPM, ensuring efficient production. The press's design also prioritizes structural stability and durability, ensuring long-term reliability. |  |

4) Electrical control system for sheet metal punching machine The metal part stamping machine utilizes a PLC control system, allowing users to conveniently set production speed and output. The control system utilizes well-known Japanese and Taiwanese servo motors and PLCs, combined with a 7-inch human-machine interface, ensuring simple and intuitive operation. Product specifications, speed, and output can all be easily configured on the interface, making production management more efficient. |  |

Advantages of Sheet Metal Punching Machine

1) Innovative design for metal part stamping machine

The sheet metal punching machine features a completely redesigned structure, making it both economical and practical. It offers ample operating space, a movable workbench that can be easily removed from the frame for mold installation, and a simple and aesthetically pleasing design. This innovative design makes it an essential piece of metal part stamping machine for producing support profile connector for open cell ceiling, meeting market demand for a wide variety of open cell ceiling connectors.

2) Professional guidance and customization for metal part stamping machine

KINGREAL CEILING MACHINERY engineers provide professional advice on metal part stamping machine procurement, helping customers select the most suitable metal part stamping line to save costs and improve production efficiency. The sheet metal punching machine can be customized to suit the appropriate motor power and voltage based on the customer's regional power system, ensuring safe and efficient operation worldwide.

3) High quality and reliability for metal part stamping machine

Leveraging strong technical expertise and years of production experience, KINGREAL CEILING MACHINERY provides high-quality sheet metal punching machine to customers worldwide. A variety of models are available, each customized to meet specific application requirements.

4) Safety and ease of use for metal part stamping machine

This sheet metal punching machine is designed for precision and stability, ensuring safe and convenient operation. KINGREAL CEILING MACHINERY is committed to meeting customer needs, ensuring this sheet metal punching machine is a reliable choice for open cell ceiling system installations. Various safety features are incorporated into the design to protect operators.

FAQ About Sheet Metal Punching Machine

1/ Is metal stamping hard?

Using a KINGREAL CEILING MACHINERY metal part stamping machine is a convenient method for metal stamping. By choosing a sheet metal punching machine with the appropriate pressure capacity, you can easily obtain high-quality finished products.

2/What does a metal part stamping machine do?

Sheet metal punching machines use processes such as bending, punching, embossing, or coining to transform metal sheets into parts or products of specific shapes. By applying high pressure through dies, they can produce a wide range of products, from simple components to complex precision parts.

3/What industries use metal part stamping machines?

KINGREAL CEILING MACHINERY sheet metal punching machine is widely used in the automotive, electric mobility, electronics, and medical device manufacturing industries. For more information, please contact KINGREAL.

4/Can metal part stamping machines be customized?

Absolutely! KINGREAL CEILING MACHINERY sheet metal punching machines can be customized according to customer requirements. KINGREAL CEILING MACHINERY engineers will tailor a metal part stamping machine specifically for you, based on the needs of your particular production tasks.

5/What safety features are included in sheet metal punching machines?

KINGREAL CEILING MACHINERY metal part stamping machines are equipped with various safety features, such as emergency stop buttons, light curtains, safety interlocks, and enclosed operating areas, to protect operators during machine operation. These systems automatically stop the machine when a dangerous situation is detected, thus reducing the likelihood of accidents.

Information About Sheet Metal Punching Machine

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)