Kazakhstan Project: Facade Panel Making Machine

This week, KINGREAL CEILING MACHINERY engineers successfully completed the installation of a facade panel making machine for a customer in Kazakhstan. As an important piece of equipment in the modern construction industry, facade panel roll forming machines are widely used in the construction of building facades and interior walls. In this article, KINGREAL CEILING MACHINERY will delve into the entire process of collaborating with our Kazakhstan customer, reviewing the important milestones and key aspects of the facade panel making machine project.

◀Facade Panel Roll Forming Machine Project Background

With the rapid development of the construction industry, Kazakhstan's demand for efficient and precise construction materials and facade panel making machine has gradually increased. Leveraging its technological advantages in the field of facade panel roll forming machines, KINGREAL CEILING MACHINERY collaborated with a local customer. This facade panel making machine not only improves production efficiency but also ensures the quality of wall cladding panels, meeting the diverse needs of the market for building materials.

◀Facade Panel Roll Forming Machine Inspection Phase

After the facade panel making machine was manufactured, the KINGREAL CEILING MACHINERY team immediately initiated a detailed inspection procedure. To ensure that the facade panel roll forming machine met the requirements of the Kazakhstan customer, KINGREAL CEILING MACHINERY staff first conducted comprehensive performance tests on the facade panel making machine. The tests included equipment positioning and installation, parameter debugging, no-load trial runs, and full-load cutting tests. Every step was strictly controlled to ensure that the facade panel roll forming machine could be stably put into subsequent production. Through multiple adjustments and inspections, all performance indicators of the facade panel making machine ultimately met the preset standards and were approved by the Kazakhstan customer. The customer was very satisfied with the performance of the facade panel roll forming machine and agreed to proceed with shipment.

◀Facade Panel Making Machine Shipment Process

KINGREAL CEILING MACHINERY staff meticulously packaged each key component of the facade panel making machine, such as the decoiler, leveling machine, roll forming machine, and cutting station. To prevent dust and scratches during transportation, all components were protected with film wrapping. At the same time, KINGREAL CEILING MACHINERY staff affixed corresponding labels to each component of the facade panel roll forming machine, indicating the component name, to facilitate quick verification by the Kazakhstan customer upon receipt.

During shipment, the KINGREAL CEILING MACHINERY team efficiently and smoothly loaded all components of the facade panel making machine onto a large truck using electric pallet trucks and overhead cranes. After loading, multiple high-strength straps were used for reinforcement and securing to ensure safe and stable transportation. The entire shipping process strictly followed operational procedures; every step, from component protection and labeling management to loading and securing, was implemented. This comprehensive set of protective measures not only ensured the integrity of the facade panel roll forming machine during transportation but also facilitated the subsequent receiving and verification process for the Kazakhstan customer, ensuring the efficiency and orderliness of the entire shipment.

◀Facade Panel Making Machine Installation and Commissioning

After the facade panel roll forming machine successfully arrived at the Kazakhstan customer's factory, KINGREAL CEILING MACHINERY immediately dispatched professional engineers to the site for installation. The KINGREAL CEILING MACHINERY engineers systematically carried out their work at the Kazakhstan customer's factory, from unpacking the facade panel making machine and assessing the appearance of each component to the installation of all parts. The entire process was very orderly.

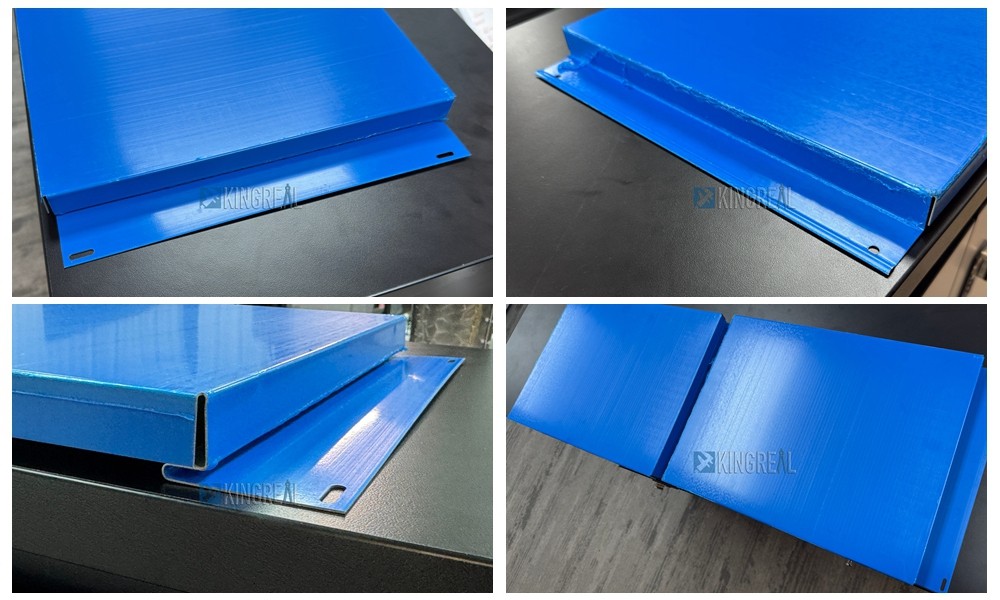

With the assistance of the Kazakhstan workers, the facade panel roll forming machine was quickly installed. After the installation, the KINGREAL CEILING MACHINERY engineers conducted a test run of the facade panel making machine, using metal coils for production testing, observing the equipment's operating status and the quality of the finished products. During the commissioning process, the KINGREAL CEILING MACHINERY engineers adjusted the facade panel roll forming machine parameters in real time based on the operating status to ensure the equipment operated at its optimal state.

◀Facade Panel Making Machine Operation Training

After the facade panel making machine installation was completed, to ensure that the Kazakhstan customer could successfully operate the facade panel roll forming machine, KINGREAL CEILING MACHINERY engineers also conducted a series of operation training sessions. The training included how to correctly start and stop the facade panel making machine, how to adjust production parameters, and how to change molds, among other key operations.

KINGREAL CEILING MACHINERY goal was to ensure that the Kazakhstan workers could independently operate the facade panel roll forming machine and respond quickly to any problems. Through repeated demonstrations and practice, all Kazakhstan workers were ultimately able to skillfully operate the facade panel making machine.

Conclusion

The successful implementation of this facade panel making machine project in Kazakhstan fully demonstrates KINGREAL CEILING MACHINERY professional capabilities and service level in facade panel roll forming machine manufacturing, transportation, and installation and commissioning. Currently, the facade panel making machine is operating stably in the Kazakhstan customer's factory, providing the customer with efficient production and high-precision finished products that meet market demand standards.

The Kazakhstan customer expressed their sincere gratitude to the KINGREAL CEILING MACHINERY team, believing that KINGREAL CEILING MACHINERY professional service provided strong support for their production efficiency and product quality.

Get the latest price? We'll respond as soon as possible(within 12 hours)