Case:Linear Strip Ceiling Machine

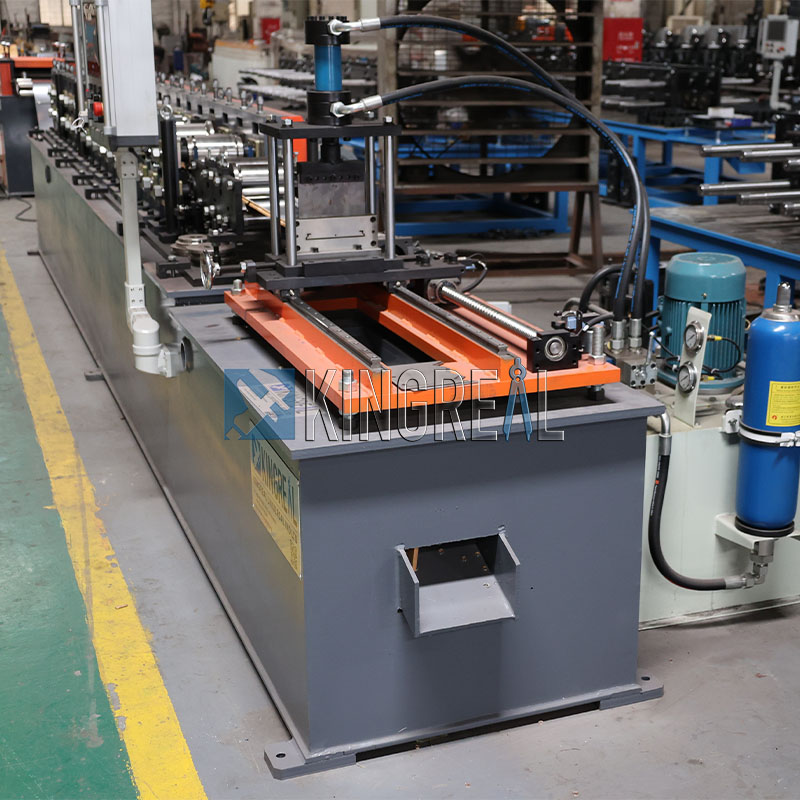

The linear strip ceiling machine is KINGREAL CEILING MACHINERY featured equipment, which can provide linear strip ceiling solutions of various types and sizes according to the actual production needs of customers. So far, KINGREAL CEILING MACHINERY linear strip ceiling making machines with punching station, multi-specification linear strip ceiling machines, single-specification linear strip ceiling machines and other types have been successfully shipped to customer factories in Qatar, the United States, the United Kingdom, the Netherlands, Russia and other countries. In this article, KINGREAL CEILING MACHINERY will introduce the different manufacturing solutions of the linear strip ceiling making machine in detail and share several successful project cases. If you are interested in the linear strip ceiling machine, please come to consult KINGREAL CEILING MACHINERY! |  |

Linear strip ceiling making machine with punching station in the UK

Demands of British customers

This British customer is from the construction industry and focuses on the production of perforated linear strip ceilings. They hope to be able to directly manufacture perforated linear strip ceilings during the production process. Previously, their production process required punching holes with a machine first, and then putting the punched metal coil into the linear strip ceiling machine for processing. This process is not only time-consuming, but also requires the use of two machines, which greatly reduces the overall production efficiency. In addition, British customers have specific requirements for the aperture and shape of the punching holes, hoping to achieve personalized customization.

Solution Discussion KINGREAL CEILING MACHINERY engineers discussed their needs in detail with the British customers and proposed a solution to equip the linear strip ceiling making machine with a punching station. This punching station can complete the entire process of punching and forming on the same linear strip ceiling making machine, thus simplifying the production process. In order to meet the British customers' requirements for punching hole diameter and hole type, KINGREAL CEILING MACHINERY provides customized punching die design to ensure the accuracy and consistency of each hole position. With this design, British customers can not only improve production efficiency, but also reduce equipment investment and operation complexity. |  |

UK customer feedback After using this linear strip ceiling machine with punching station, British customers expressed great satisfaction. They found that production efficiency was significantly improved, the production process became smoother, and the frequency of linear strip ceiling machine maintenance was reduced. At the same time, British customers also highly praised the accuracy and consistency of punching, believing that such linear strip ceiling making machine greatly enhanced their market competitiveness. |  |

Multi-specification linear strip ceiling machine in Russia

Russian customer needs

This Russian customer is a linear strip ceiling seller, focusing on providing linear strip ceilings of various specifications for the construction and decoration industries. Due to the diverse needs of its customer base, they hope to be able to produce linear strip ceilings of various sizes with one linear strip ceiling making machine instead of purchasing multiple devices to meet different production needs. Russian customers hope that this linear strip ceiling machine can quickly and flexibly adjust production parameters to adapt to different order requirements.

Solution discussion KINGREAL CEILING MACHINERY designed a multi-specification linear strip ceiling making machine to meet the needs of Russian customers. By modifying the parameters on the control panel, the roller of the roll forming machine can automatically adjust the width to produce linear strip ceilings with a width range of 150-300mm. This design enables Russian customers to quickly switch production modes to meet the order needs of different customers. In addition, KINGREAL CEILING MACHINERY also ensures the stability and production efficiency of the linear strip ceiling machine, and the linear strip ceiling making machine can still maintain efficient operation even when the parameters are frequently adjusted. |  |

Russian customer feedback Russian customers expressed great satisfaction after using this multi-specification linear strip ceiling making machine. They believe that this flexible design not only avoids the need to purchase multiple devices, but also greatly saves money and production space. The production efficiency of Russian customers has increased by more than 30%, and at the same time, it can better meet the changing needs of the market and enhance their competitiveness. |  |

Single-specification linear strip ceiling machine in India

Demands of Indian customers

This Indian customer focuses on producing linear strip ceilings of a single size, mainly for the construction and decoration industry in the local market. Indian customers hope to have a fully automated linear strip ceiling making machine to improve production efficiency, reduce labor costs, and ensure the quality consistency of each linear strip ceiling. Due to its large production volume, Indian customers particularly emphasize the requirements for linear strip ceiling machine operation stability.

Solution discussion KINGREAL CEILING MACHINERY staff had in-depth exchanges with customers and confirmed the types and specifications of linear strip ceilings to be produced. In order to meet the needs of Indian customers, KINGREAL CEILING MACHINERY designed a fully automatic linear strip ceiling machine equipped with precision components such as decoiler, precision leveling machine, roll forming machine, shearing station, etc., forming a complete linear strip ceiling making machine. This fully automated design not only reduces the need for manual intervention, but also ensures the efficiency and consistency of the production process. |  |

Feedback from Indian customers After using this fully automatic linear strip ceiling machine, Indian customers gave extremely positive feedback. They pointed out that the high degree of automation of the linear strip ceiling machine greatly liberated human resources and increased production efficiency by more than 50%. At the same time, Indian customers were also satisfied with the consistency of production and believed that the introduction of this linear strip ceiling making machine enabled them to better meet market demand. |  |

Linear strip ceiling making machine in Canada

Demands of Canadian customers

Customers from Canada have rich experience in the manufacture of aluminum products. They need a linear strip ceiling making machine with high leveling accuracy, which is specially used for processing aluminum coils. Canadian customers pay special attention to the leveling effect and require the equipment to be able to process aluminum coils with a thickness of 0.4-0.6mm to ensure the quality of the final product.

Solution discussion In order to meet the high leveling needs of Canadian customers, KINGREAL CEILING MACHINERY equipped the linear strip ceiling machine with a leveling machine with 21 rollers. The more rollers, the better the leveling effect, which can effectively eliminate the deformation and corrugation of aluminum coils. In addition, KINGREAL CEILING MACHINERY has also optimized the design according to the characteristics of aluminum coils to ensure that the material will not be damaged during the processing, thereby improving production efficiency and product quality. |  |

Feedback from Canadian customers After using this linear strip ceiling machine, Canadian customers expressed great satisfaction with the leveling effect. They believe that the production speed is fast and the quality of the linear strip ceilings has been significantly improved, which meets their high standards for products. Canadian customers said that the performance of the linear strip ceiling making machine exceeded their expectations and they will continue to cooperate with KINGREAL CEILING MACHINERY in the future. |  |

Linear strip ceiling machine & linear strip ceiling carrier machine in Qatar

Customer needs in Qatar

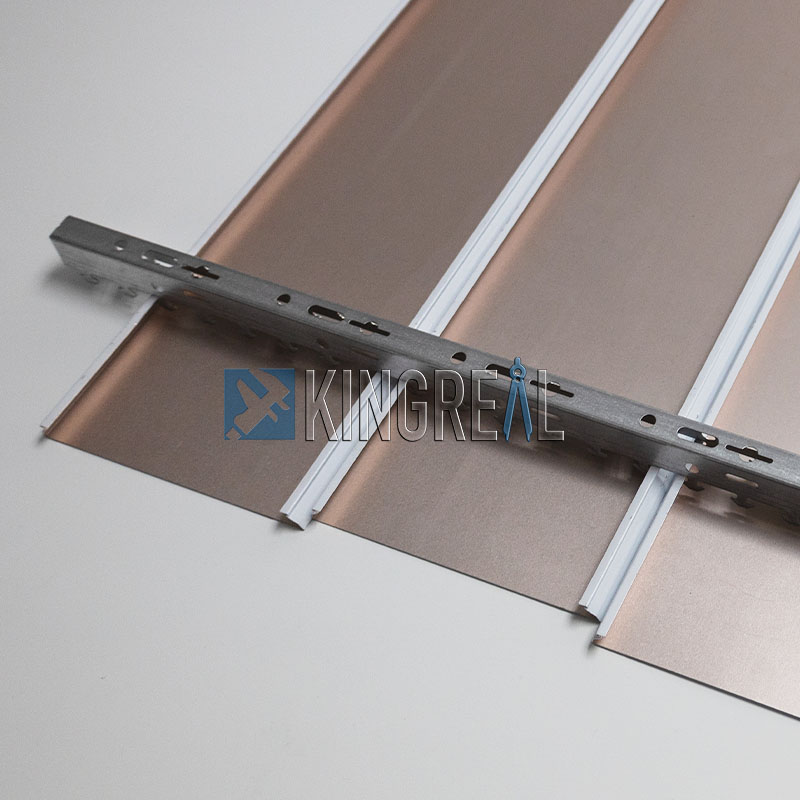

Customers in Qatar hope that KINGREAL CEILING MACHINERY can provide a complete linear strip ceiling system, including a linear strip ceiling making machine and a linear strip ceiling carrier machine. Customers in Qatar hope that the two devices can be perfectly matched in parameters and performance to achieve efficient production.

Solution discussion KINGREAL CEILING MACHINERY staff recommended a combination of a linear strip ceiling machine and a linear strip ceiling carrier machine to Qatar customers. The linear strip ceiling making machine is responsible for producing linear strip ceilings, while the linear strip ceiling carrier machine is used to produce the linear strip ceiling carrier used with the linear strip ceilings. With this combination, Qatar customers can complete a complete linear strip ceiling system, greatly improving production efficiency and product consistency. |  |

Feedback from Qatar customers Qatar customers purchased these two machines from KINGREAL CEILING MACHINERY and expressed great satisfaction. They believe that the parameters between the linear strip ceiling machine and linear strip ceiling carrier machine can be well matched, they are very smooth to use, and production efficiency has been significantly improved. In addition, Qatar customers also said that having a complete production system enables them to better meet market demand and improve business flexibility. |  |

Get the latest price? We'll respond as soon as possible(within 12 hours)