Linear Strip Ceiling Machine in Vietnam

In January this year, KINGREAL CEILING MACHINERY engineers traveled to Vietnam to install a linear strip ceiling machinefor a customer. This process not only demonstrated KINGREAL CEILING MACHINERY strength and experience as a professional linear strip ceiling production line supplier but also further consolidated KINGREAL CEILING MACHINERY position in the international market. So far, KINGREAL CEILING MACHINERY has successfully shipped high-quality and efficient linear strip ceiling machines to many countries such as India, Indonesia, the United Arab Emirates, Russia, Greece, Turkey, and Canada, accumulating rich industry experience along the way.

Linear Strip Ceiling Machine Installation Process

The installation of the linear strip ceiling machine is a multi-faceted process that requires careful planning and execution. During the installation in Vietnam, KINGREAL CEILING MACHINERY engineers first laid out the various components of the linear strip ceiling production line one by one. These components include the decoiler, precision leveling machine, main roll forming machine, and shearing stations. Each component is indispensable and plays a crucial role in the overall functionality of the linear strip ceiling machine. A reasonable installation sequence and precise debugging are key to ensuring smooth production.

1. Check Component Status

Before starting the installation, KINGREAL CEILING MACHINERY engineers meticulously checked the surface status of each component of the linear strip ceiling production line. This inspection was essential to ensure that there were no scratches, dents, or other damages that could hinder the performance of the machine. By detecting any potential issues at this early stage, the engineers were able to avoid downtime and losses that could arise from component problems during production.

2. Step-by-Step Installation

The installation process unfolds in several systematic steps:

1

Decoiler Installation

The first step involved installing the decoiler, which is responsible for unwinding the coils of material that will be processed. Engineers ensured that the decoiler was securely positioned and capable of handling the weight and dimensions of the coils effectively.

2

Precision Leveling Machine

Following the decoiler, the precision leveling machine was installed. This machine is critical for ensuring that the coils are perfectly flat before they enter the main roll forming machine. Any irregularities in the material could lead to defects in the finished product, so this step is crucial for quality assurance.

3

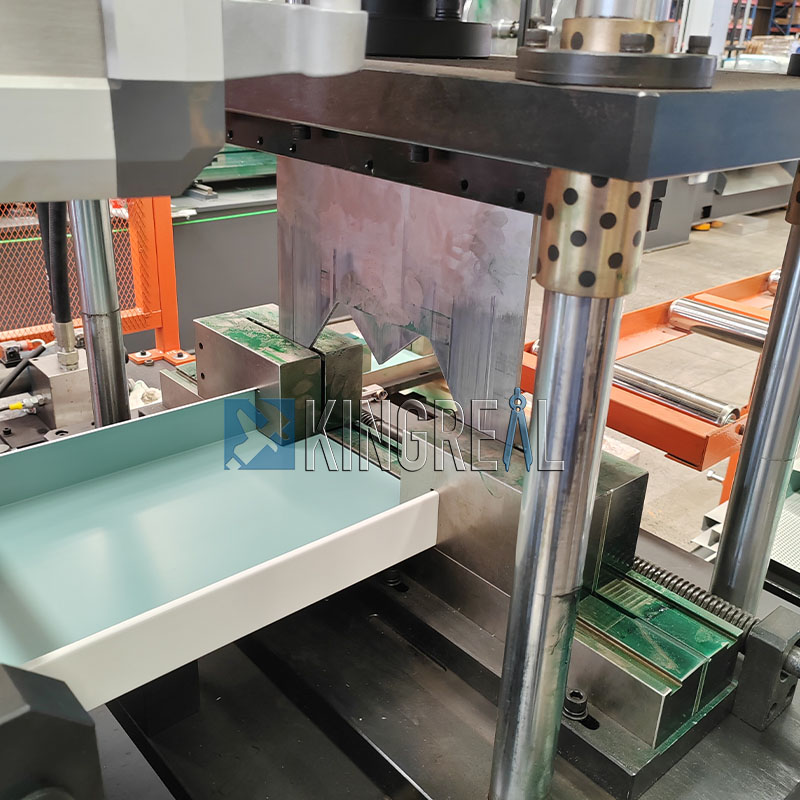

Main Roll Forming Machine

The main roll forming machine is a crucial component of the linear strip ceiling production line. It is responsible for shaping the metal strips into the desired profiles. Utilizing a series of rollers, the machine gradually bends and forms the material to achieve specific cross-sectional shapes required for linear strip ceilings. This process ensures precision and consistency in the product, allowing for high-quality results that meet customer specifications.

4

Shearing Station

The shearing station is another vital part of the assembly. Its primary function is to cut the formed metal strips to the required lengths. Equipped with precision cutting tools, the shearing station ensures clean and accurate cuts, which are essential for maintaining the quality of the finished product. This component allows for flexibility in production, enabling the manufacturer to produce strips of various lengths as dictated by customer needs or project requirements.

3. Adjustment and Testing

After the installation of the linear strip ceiling machine was completed, the engineers proceeded to test its functionality. They loaded Gi steel and aluminum coils into the linear strip ceiling production line and began the calibration process. On the control panel, various parameters were adjusted, and multiple tests were conducted to ensure that the linear strip ceiling machine could produce stably and efficiently.

This testing phase is vital as it directly impacts production efficiency and product quality. The engineers verified that the linear strip ceiling machine could achieve a maximum production speed of 30 m/min and evaluated the quality of the produced linear strip ceilings. This thorough testing ensured that the machine was ready for full-scale production, meeting both quality and performance standards.

Vietnamese Customer Evaluation of Linear Strip Ceiling Machine

After completing the installation and commissioning of the linear strip ceiling production line, the Vietnamese customer expressed high satisfaction with KINGREAL CEILING MACHINERY product. They noted that the linear strip ceiling machine met their current production needs perfectly, especially in terms of fully automated production. The fully automated design not only reduces labor costs but also significantly improves production speed and ensures the accuracy and quality of the finished product.

Improved Production Efficiency

The Vietnamese customer emphasized that the high efficiency of the linear strip ceiling machine enabled them to complete a greater number of production tasks in a shorter time frame. This increase in efficiency has resulted in significant economic benefits for their business. With the ability to produce more in less time, they have gained a competitive edge in a crowded market.

Accurate Production Capacity

Using the control panel, the Vietnamese customer can easily input various production parameters. The forming group rollers can adjust the width according to the specified settings, allowing for the production of linear strip ceilings in different sizes. This flexibility enables the customer to cater to diverse market demands, offering personalized products that meet specific customer requirements.

Through the successful installation of the linear strip ceiling machine in Vietnam, KINGREAL CEILING MACHINERY has showcased its professional technical capabilities and service excellence. The high praise from Vietnamese customers serves as the best testament to the performance and quality of KINGREAL CEILING MACHINERY linear strip ceiling production line.

Looking ahead, KINGREAL CEILING MACHINERY remains committed to providing customers with more efficient and higher-quality linear strip ceiling machine solutions. This commitment not only helps our clients stand out in the fierce market competition but also ensures that KINGREAL CEILING MACHINERY continue to lead in the global market for linear strip ceiling production lines. Our goal has always been to become a leading supplier through continuous innovation and high-quality services, consistently meeting the evolving needs of the industry and our valued customers.

As KINGREAL CEILING MACHINERY expands our reach into new markets and strengthen our existing partnerships, we are excited about the future of KINGREAL CEILING MACHINERY and the role we will play in shaping the future of linear strip ceiling machine manufacturing solutions. Whether it’s through improved technology, better customer support, or innovative design, we are dedicated to helping our clients succeed in the dynamic world of manufacturing.

Get the latest price? We'll respond as soon as possible(within 12 hours)