How to improve efficiency of baffle ceiling machine?

2025-05-08 17:00

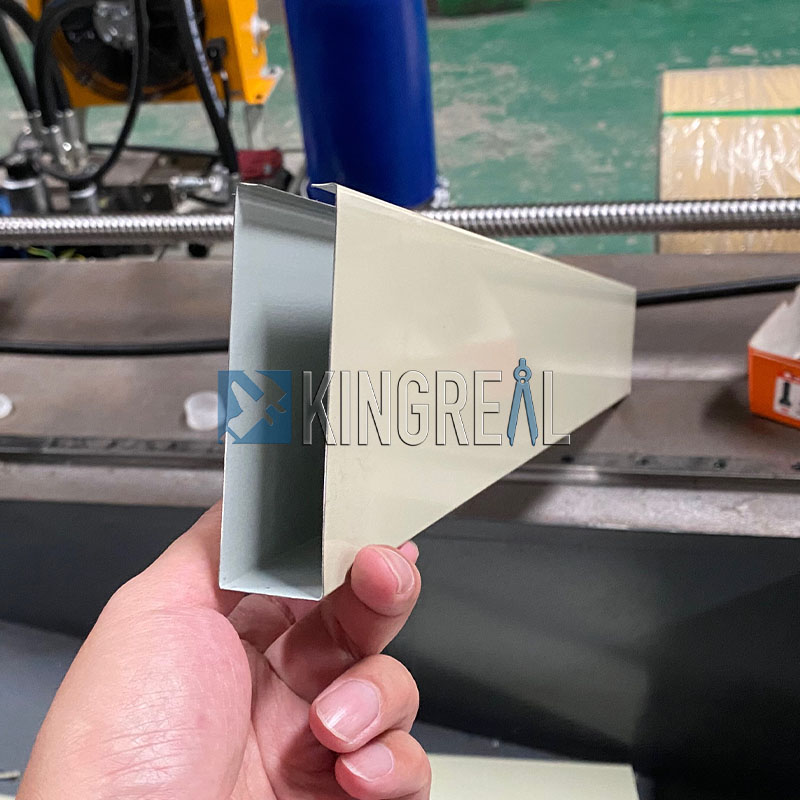

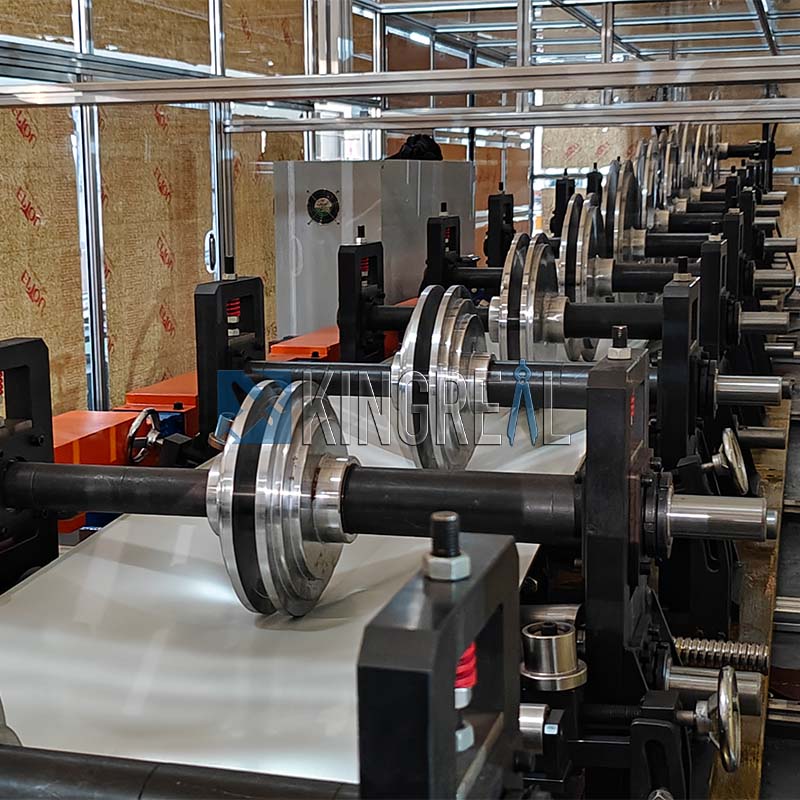

Baffle ceiling machine is a kind of mechanical equipment specially used for producing baffle ceiling. Its main function is to process metal raw materials into baffle products of different sizes and types, such as U-shaped baffle, V-shaped baffle and U-shaped baffle with U-bent, through precision parts such as decoiler, precision leveling machine, main roll forming machine and shearing station.

With the rapid development of the construction and decoration industry, the importance of baffle ceiling making machine in the market is increasing, especially in terms of production efficiency. In this article, KINGREAL CEILING MACHINERY will discuss with you the importance of baffle ceiling machine to the market and propose practical methods to improve the production efficiency of baffle ceiling making machine.

Reasons for Importance of Baffle Ceiling Machine to Market

High degree of automation

The design and manufacturing of baffle ceiling making machine focuses on automation, so that the production process does not require too much human intervention. This efficient automation system not only reduces labor costs, but also significantly improves production speed and product consistency. Through the automated production process, baffle ceiling making machine can complete the production of a large number of products in a short time to meet customer needs.

Wide application of finished products

Baffle ceiling produced by baffle ceiling making machine is widely used in various construction and decoration projects, such as commercial office buildings, public facilities, shopping malls, hotels, etc. Due to the superior performance of baffle ceiling in terms of beauty, sound insulation, ventilation, etc., its market demand continues to increase. This demand has promoted the continuous improvement of baffle ceiling making machine production capacity and efficiency, making it an indispensable and important baffle ceiling machine in the industry.

The necessity of improving production efficiency

In the fierce market competition, improving the production efficiency of baffle ceiling machinehas become an important task for manufacturers. Efficient production can not only reduce the production cost of unit products, but also increase delivery speed and enhance customer satisfaction. Therefore, exploring ways to improve the production efficiency of baffle ceiling making machine is crucial for the long-term development of enterprises.

Video About Baffle Ceiling Machine

Methods to Improve Production Efficiency of Baffle Ceiling Machine

1. Full communication with engineers during design

During the design stage of baffle ceiling making machine, it is very important to fully communicate with engineers. Manufacturers should elaborate on their own production needs and actual conditions to achieve a perfect match between machine parameters and production reality. Through this in-depth communication, engineers can optimize the design of baffle ceiling machine according to factors such as production scale, material type and product specifications, so that it can achieve optimal performance during the production process.

2. Add accessories to improve functions

According to their own production situation, appropriately adding accessories to baffle ceiling machine can significantly improve production efficiency. The following are several recommended accessories and their functions:

2.1 Decoiler equipped with a feeding trolley

Equipping the decoiler with a feeding trolley can realize automatic feeding of the baffle ceiling machine to the decoiler, avoiding the tedious manual handling. This not only improves production efficiency, but also reduces the labor intensity of workers and reduces labor costs. The use of the feeding trolley can greatly increase the supply speed of raw materials and ensure the continuous operation of the baffle ceiling making machine.

2.2 Baffle ceiling machine equipped with a protective shield

The roll forming machine is equipped with a protective shield to effectively protect the safety of workers and prevent accidental injuries during operation from affecting the production progress. The design of the protective shield should meet safety standards and not affect the normal operation of the baffle ceiling machine. A safe working environment can improve the work enthusiasm of workers, thereby indirectly improving production efficiency.

3. Regular maintenance and care

Regular maintenance and care of the baffle ceiling machine is the basis for ensuring its efficient operation. Maintenance should include cleaning, lubrication and inspection of the wear of each component. Through regular inspections, potential problems can be discovered in time to prevent production stagnation caused by baffle ceiling making machine failure. For example, regular inspection and maintenance of the lubrication system can ensure the smooth operation of mechanical parts, reduce friction and wear, and thus extend the service life of the baffle ceiling making machine.

4. Training employees' operating skills

The operating skills of employees directly affect the production efficiency of the baffle ceiling machine. Therefore, regular training of operators to improve their understanding and operation ability of the baffle ceiling machine is an important measure to improve production efficiency. The training content should include basic operation, troubleshooting, maintenance and other aspects of the baffle ceiling making machine. Skilled operators can quickly respond to various problems in production and ensure the smooth operation of the baffle ceiling making machine.

5. Data monitoring and analysis

The development of modern technology has made data monitoring and analysis an important means to improve production efficiency. The baffle ceiling machine can be equipped with an intelligent monitoring system to monitor various data in the production process in real time, such as production speed, product quality and baffle ceiling machine operation status. Through the analysis of data, enterprises can adjust production strategies in time, optimize production processes, and further improve efficiency. For example, if the production speed is detected to be reduced, the cause can be quickly found and adjusted to avoid unnecessary losses.

6. Optimize production processes

Finally, optimizing production processes is the key to improving the production efficiency of baffle ceiling machines. By rationally planning the layout of the production line and reducing the ineffective time between processes, the overall production efficiency can be significantly improved. The optimization of the production process should be adjusted according to the actual production situation to ensure smooth connection of each link and reduce material handling and waiting time.

Get the latest price? We'll respond as soon as possible(within 12 hours)