Kazakhstan Customers at Baffle Ceiling Machine Factory

2025-09-28 17:00

This month, KINGREAL CEILING MACHINERY staff warmly welcomed a customer from Kazakhstan for an in-depth tour of baffle ceiling machine. The Kazakhstan customer, having decided to expand into the baffle ceiling market, sought an efficient and reliable baffle ceiling making machine. The primary purpose of the visit was to evaluate whether KINGREAL CEILING MACHINERY baffle ceiling machine could meet their project needs.

Before the Kazakhstan customer's arrival, KINGREAL CEILING MACHINERY staff conducted extensive online discussions with the customer, gaining a detailed understanding of their needs and evaluation priorities. As a result, upon their arrival at the KINGREAL CEILING MACHINERY factory, the visit was exceptionally well-organized and efficient.

Baffle Ceiling Making Machine Tour Process

1. Confirming PLC Control Panel Functions of Baffle Ceiling Machine

Upon entering the factory, the Kazakhstan customer was first directed to the baffle ceiling making machine's operating area. A KINGREAL CEILING MACHINERY engineer enthusiastically demonstrated the baffle ceiling machine's PLC control panel, a core component that allows for flexible configuration and adjustment of production parameters. The KINGREAL CEILING MACHINERY engineer provided a detailed explanation of how to set parameters such as speed, cutting length, and output using the control panel.

Under the guidance of KINGREAL CEILING MACHINERY engineers, the Kazakhstan customer gained a deeper understanding of the PLC control panel's functions and confirmed its ease of operation and efficiency. This control panel enables the Kazakhstan customer to precisely control the baffle ceiling making machine, ensuring accurate control of every detail in the production process.

2. Evaluating Width Adjustment Capability of the Rollers

Next, the Kazakhstan customer evaluated the width adjustment capability of the roller assembly of the baffle ceiling machine. KINGREAL CEILING MACHINERY baffle ceiling making machine series includes 100mm height, 200mm height, and 300mm height baffle ceiling machines, capable of producing finished products in a wide range of widths and heights. During this visit, KINGREAL CEILING MACHINERY staff demonstrated the 200mm height baffle ceiling machine to the Kazakhstan customer.

The Kazakhstan customer carefully observed the baffle ceiling making machine's adjustment speed and accuracy. The KINGREAL CEILING MACHINERY baffle ceiling machine can quickly and accurately adjust widths. During actual testing, this baffle ceiling making machine successfully completed production tasks with heights ranging from 35-200mm and widths from 30-100mm, fully demonstrating its efficient adjustability.

3. Evaluating Baffle Ceiling Machine's Operation Process

After evaluating the baffle ceiling making machine's adjustability, the Kazakhstan customer further inspected its operation. KINGREAL CEILING MACHINERY staff accompanied the Kazakhstan customer throughout the entire process, demonstrating the baffle ceiling machine's operation. During the observation, the Kazakhstan customer noted that the baffle ceiling making machine can be fully automated simply by setting parameters on the PLC control panel. This not only improves production efficiency but also reduces the complexity of manual operation.

The Kazakhstan customer expressed satisfaction with the baffle ceiling machine's smooth operation and believed that this efficient automated production model is well suited to their future market needs. The smooth operation of the entire production line has given the Kazakhstan customer greater confidence in the overall performance of the KINGREAL CEILING MACHINERY baffle ceiling machine.

4. Evaluating the Baffle Ceiling Precision

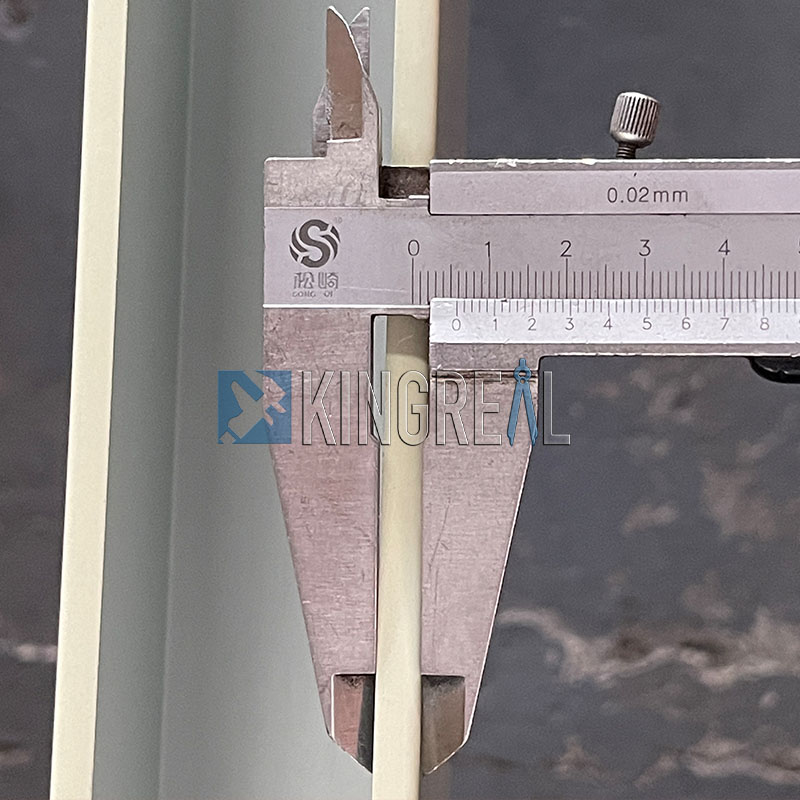

Finally, the Kazakhstan customer evaluated the precision of the finished products produced by the KINGREAL CEILING MACHINERY baffle ceiling machine. To ensure the quality of the baffle ceiling making machine, the Kazakhstan customer prepared measuring tools such as tape measures, calipers, and angle rulers, and conducted detailed measurements of the finished products. According to the Kazakhstan customer's measurement standards, the shearing accuracy of the baffle ceiling produced by the KINGREAL CEILING MACHINERY baffle ceiling machine can reach L ≤ 3000mm ± 1.0mm.

After measurement, the Kazakhstan customer was delighted to find that the finished products produced by the KINGREAL CEILING MACHINERY baffle ceiling making machine not only met the required precision, but also had a smooth, burr-free surface and no roller marks. The base also maintained excellent rigidity and stability. These test results have strengthened the Kazakhstan customer's confidence in the KINGREAL CEILING MACHINERY baffle ceiling machine, believing it can fully meet his needs in expanding into new markets.

The Kazakhstan customer's visit to the KINGREAL CEILING MACHINERY baffle ceiling machine factory fully demonstrated KINGREAL CEILING MACHINERY expertise and technological advantages in the baffle ceiling making machine field. By understanding the functions of the PLC control panel, evaluating the width and narrowness adjustment capabilities of the roller group, observing the baffle ceiling machine operation process and measuring the accuracy of the finished product, the Kazakhstan customer gained a comprehensive understanding of the various performance of the baffle ceiling making machine.

Get the latest price? We'll respond as soon as possible(within 12 hours)